Technologies of the workpiece of bulk feed. "Veliza Novaya", the newspaper MO "Velizky district" of the Smolensk region

Lecture number 6. Subject: Technology billet feed

Green conveyor - this is an uninterrupted supply of animals with green feed during the entire pasture period in size, fully satisfying the need for livestock.

Green feed is considered biologically most complete for animals. In the pasture period, young animals develop all types normally develops, acquires resistance to diseases. Green food is the cheapest. Cost of livestock production in summer period 1.5-2 times lower than in winter.

Cultures of the green conveyor must meet the following basic requirements: to give a stable high yield The green mass of high feed advantages and well-eaten animals, have different expiration date to the blending, to have a beneficial effect on the health and productivity of animals, to be suitable for mechanized cleaning, give cheap food.

The main cultures of the green conveyor in many areas are perennial herbs: from legumes - clover meadow, hybrid and creeping (on pasture), Lucerne, Esparcet, Donnik; From the cereals - Timofeevka meadow, hedgehog team, firewood, datdsy meadow, canary cane, linen, and other hedgehog, fire, can give early green food. Herbs are sown in pure form and in mixtures.

From the early spring crops to the green conveyor include Vika Yarovoy, peas, fodder lupine, lentil, rank, rape, rigors, mustard, mustard, sneakers, depending on local conditions.

Of the disappeared crops in the green conveyor include root, cabbage, messenger, Topinambur.

Three types of green conveyor distinguish: 1. Natural when using only natural pastures and hayfields; 2. artificial when using seeded perennial and annual herbs, feed crops; 3. Combined, using natural and cultural pastures, as well as field feed crops.

The mixed line of the conveyor got the most distribution in all zones of our country. The main part of the green feed in this case, animals are obtained from cultural pastures and natural land, in periods of poor growing grass-with crops Perennial and annual herbs and cultures.

When building a green conveyor, it is important to absolute feed crops correctly, capable of ensuring uninterrupted flow of green kerma during the pasture period.

When organizing a green conveyor, it is important to determine the method of using the herb. Three methods are known: pasture, stall and combined. The pasture way provides for the roasting of grass on the root, it is cheaper than others. Stall method involves the feeding of freshly abundant mass in the feeders; It requires additional funds On mowing, transportation and distribution of mass, but the green mass is better eaten. In the combined method of the thhassic combined with a fantastic green mass in the feeders. The introduction of a green conveyor contributes to uninterrupted livestock provision of full feed throughout the summer season.

Hay. In the feed diet of animals hay makes a significant proportion. Hayer nutrition is high compared to other coarse feeds.

In the creation of a solid feed base, important acquires rational use Senokosov, collecting hay without loss and the best quality.

When cleaning the hay, it should be borne in mind that various parts of the same plants have an unequal feed value. For example, plant leaves, inflorescences, the tops of the stems have more valuable feed advantages.

One of the most important tasks when cleaning herbs on the hay is to obtain the greatest collection of hay and the preservation of its nutritionality, which largely depends on the proper conduct of individual cleaning processes.

Particular attention should be drawn to the fight against losses. Destination with the timing of the cat, improper cleaning, significant gaps between making herbs, shrinking, shocking and discharging lead to great losses. With incorrect drying and non-compliance with other rules of cleaning, the quality of the hay is reduced by 20--25%.

therefore important conditions High quality hay and elimination with cleaning losses - timely mowing of grass, compliance with the required height of the mowing, proper cracking, chopping and springs, mechanization of the main cleaning processes, as well as the proper storage of the hay.

Herbs - one of the main, decisive processes, on which the amount and the quality of the hay depends.

Skill time. The greatest harvest of the hay and raw protein is obtained when graveing \u200b\u200bherbs during a colet or flowering.

Late beveled herbs rough, tough and poorly eaten animals. In addition, when delayed with cleaning on hay-axes appear in a large number of weed herbs, poorly eaten by animals.

As too early, so and very later, the messenger of the grassland is negatively reflected on the productivity of hay roads not only in this year, but also in the next, since the nutrients in plants are accumulated at a period of rings or bootonization and this process ends during the flowering period. In later phases of growth and plant development, the number of these substances decreases.

Second ducks. From the timely conduct of the first Ukhosa depends on the receipt of a full-fledged second force on the hay. With a second force (Otava), it is obtained from 25 to 50% of the hay compared with the harvest of the first hide, and sometimes more. The quality of the hay is usually higher than from the first, which is explained by a more tender mass. Otava Contains a protein of 1.5-2 times more than the grass of the main Ukos.

Grocery grass. When cleaning herbs, it is of great importance and the right handbank, otherwise large losses occur, especially the most nutrient parts of plants - inflorescences and leaves.

Raking the grass is needed in equal rolls, this is facilitated by the subsequent tightening of the hay in the shock or skid. Raking better across the processes, since with such a method less losses than when driving along the processes. Skilled grass can not be left for a long time in processes; In order not to be unnecessary losses, it is best to raw it on the day of mowing.

Drying hay In the shortest possible time reduces losses nutrients. The entire process of drying the grass is reduced to bring water from the plants as a result of removal (evaporation) of water from plants, the moisture content in the hae is not more than 17, and in herbal flour - up to 8-13%. Remove the water from the grass with air drying in the field (in the punks, rolls, on the mandrels, in the copper, etc.) or when drying in the seventures by compulsory ventilation, the usual genuine or heated air. If the grass is dried in drying plants with heated air with high temperature, then such a drying is called artificial.

For drying grass, certain temperatures are needed, relative humidity and air movement. To accelerate drying in the field, sporing, hounding, shock, drying with ventilation, etc., apply the drying of the stems is achieved by their ivy, which is especially important when cleaning thick-seat plants.

With a very fast artificial dryer (a few seconds or minutes) with a temperature in the first period of 800-1000 ° C and in the second - 80-100 ° C, a product (herbal flour) is obtained, in its nutritional value (protein content) and digestibility is almost no different From the source green grass.

During drying, the quality of the hay is improved as a result of biochemical processes, it becomes aromatic.

High quality assessment

The quality assessment of the hay is necessary in order to distribute the hay, depending on the feed dignity, to distribute the hay into groups, and when the content of harmful and poisonous herbs contains it and thereby prevent animal poisoning. In addition, depending on the quality assessment of the Skird Sacre and Stacks, they are distributed to the feeding of one or another cattle species. The best in the quality and nutritionalness of the hay give young cattle, dairy cows and bull-producers.

When evaluating the hay, special attention should be paid to the smell, color, the age of grass (phase of development, during which plants were beveled).

The hay, cleaned timely and in good weather, should be fragrant. The hay, spoiled from the rain, cleaned in crude weather, has a smell of mold; Brown or burned, but well-cooked smell like baked bread.

The color of the hay, cleaned in good weather, also different: cereal herbs - green, alfalfa - bright green, from clover - brownish-green, semelted herbs - Emerald green.

The quality of the hay depends also on the content of dust in it

BUT. Evaluation of botanical composition

B. Assessment of general qualities:

1. Age of plants and cleaning time

2. Color and smell:

The total assessment is as follows: very good hay - 80-100 points, good - 60-80, average - 40-60, bad - 20-40, very bad - below 20 points.

The hay is divided depending on the botanical composition and places of growing plants on the seeded bean, seeded cereal, seeded bean-cereal, natural hayfields.

It must be without signs of burner, as well as without a shallow, mold, rotary and other strangers

The color of the seeded bean and the bean-cereal hay should be from green and greenish-yellow to light-brown, hay of seeded cereal and natural hayfields - from green to yellow-green or green-brown.

Senage Prepared from lied perennial and annual herbs. For obtaining it, sowing of legumes and cereal herbs in its pure form, their mixtures, as well as the herbs of improved natural feed land. In contrast to the usual silo, the safety of which is due to the accumulation of organic acids resulting from fermentation, canning the haypt is achieved due to the physiological dryness of the medium at which the water-holding power of plant tissues exceeds the suspicious force of most bacteria. Only mold mushrooms have a significantly greater sucking force and can develop on the entered grass. Prevent the development of mold mushrooms in the feed can be insulated from air access. In the sinky mass accumulate carbon dioxide and nitrogen. The oxygen that falls into the Senago Mass when bookmarking it in the trench is rapidly consumed by developing microorganisms. Therefore, mold mushrooms that are aerobic organisms cannot develop. Such conditions are favorable for lactic acid bacteria. However, lactic acid fermentation in the Senget flows weaker than when souling, therefore, the significant accumulation of lactic acid does not occur.

The resulting feed in nutrition is almost no different from fresh herbs and willingly eaten by cattle.

Senago cooking technologyincludes the following opeframes:

1. Skill, ivy, implanting and shaking grass, in rolls;

2. Selection of herbs from rolls, its grinding and loading into vehicles;

3. Bookmark of the wedroom grass in the repository;

4. Shelter storages.

Bookmark in the wired grass in the repository. In storages should be reliable protection Senja from air access. The most fully of this requirement is satisfying the construction of a tower type.

To prevent the upper layer of the Senge in the towers of any type, it is necessary to lay a protective layer of a thickness of 30-40 cm above above.

As soon as the storage is filled, the mass in it must be immediately covered for insulation from the air.

Distinctive technological operations when bookmarking the Senate in the trenches are as follows: Tamble and subsequent shelter of the filled trench polyethylene film and layer of land, sawdust and peat.

Bookmark of the Senate in the trenches should continue not more than 3-4 days. Every day, it is necessary to lay a layer of sinking weight of 60-70 cm. On top of the mixed mass, it is advisable to launch], a layer of freshly jammed grass (30-50 cm).

Well ravenly lined with a mass of the Senge on top

Senge quality. It should be without mold, without a pock, mold and other extraneous smells. According to organoleptic and chemical indicators, Senage is divided into I, II and III classes and non-class.

The ebony is attributed to the Senage of Brown and Dark Brown, with a strong smell of honey or freshly baked rye bread, corresponding to the rest of the indicators

standard.

Silia feed

A preservative factor in the souls of feed serves the lactic acid formed by the fermentation of sugars. In addition to lactic acid, acetic, oil and other organic acids are formed in the silo, the accumulation of which adversely affects the quality of the silage.

The more sugar is contained in the plants silos, the easier it is forgotten, the greater the acidity of the silo. Normal acidity silo - pH 4-4.2. Milk acid bacteria form lactic acid mainly of simple sugars. The minimum amount of sugar required to bring the pH to 4.2 is called sugar minimum.

Depending on the ratio of the actual sugar content and sugar minimum, the plants are divided into easy-, difficult-to-seeming and non-coaling. In lightly inconsistent plants, the actual sugars content above the sugar minimum, in hard-following - below.

K. Finely showing corn, sunflower, wicco oatmeal, meadow oatava; to hard-moving - donon, vika, clover; To non-slip - Camel Spiky.

To prevent unwanted microbiological processes, the weight of the mass must be isolated as soon as possible from air access.

As a result of various processes occurring during the silage, the silo differs from "the initial mass of the almost complete absence of sugars, less content of starch and protein, but a large amount of amino acids, milk acid. The protein content in a well-cooked SI LOSE decreases by no more than 10%.

Silos from herbs occupies among juicy feeds one of the first places and in nutrition (protein content) differs little from the green feed, according to the content of digestible protein; | Silos from herbs significantly surpasses other types of silos.

Due to the high feed qualities, the silage of herbs can serve as an excellent feed, especially in winter, contributing to the increase in animal productivity. In the summer, when the insight is exactly green feed, the silos of herbs can also be used as high food.

Silos is prepared from freshly closed or exploded to humidity of 60-75% crushed mass of plants. In the silage of raw materials having a humidity of more than 75, 10-20% crushed straw is added to it.

You can silence with the addition of preservatives, carbamide and other nitrogen-containing chemicals and without them.

A valuable silo raw materials serve Lucerne, China, Pelyushka, Sudanese grass, Magnar, sorghum, as well as bean-cereal mixtures of annual herbs. For scenes you can use the grass with natural hayfields. With timely misement in these areas, you can get the second, and sometimes the third bump, especially after feeding with mineral fertilizers. When, long rainy weather, part of herbs on haysticks is advisable to clean on the silage, which, with timely cleaning, will be valuable in winter or in summer with a lack of green feed.

Technology, silage cooking. For high quality silage workpiece, not only the correct definition of the tightness of the green mass, but also carrying out the cleaning itself. First of all, you need to make as many green grass as you can remove and lay on the same day on the silage, otherwise the grass quickly loses nutritionality (sugar losses, starch, carotene); In addition, the green mass is worsened, and with long lying, it becomes unsuitable for silence due to the large loss of moisture. In unfavorable weather, a mowed green mass must be immediately shaken.

When preparing silo, the mass must be crushed. This contributes to its best seal, ousting air and thereby reducing losses as a result of the vital activity of aerobic microorganisms. The greater the humidity of the mass, the less the degree of grinding is necessary.

An important factor of scenes is a mass seal. It is necessary to compact it continuously, layerly at 20-30 cm. Fill a trench needed for 3-5 days. Immediately after filling, the silo mass is covered with Earth (20-50 cm) or a polyethylene film with a thickness of at least 0.12 mm. It can be covered with a layer of straw, but the loss of nutrients increases.

In the silage of feed rich in proteins, for example, clover, it is advisable to make frivas of lactic acid bacteria. A trench method of scenes is widespread. Trenches can be recessed, semi-brewed and ground. They must have lined walls and a solid base. The width of the earthen trenches is 9-15, the height is 2.5-3.5 m. The weight of the mass is needed daily to align over the entire surface of the trench. Before laying a silo, weigh all the green mass. Silo occurs in the amount of mass of the mass minus 15% on the so-called avgar. This is a rather inaccurate method-weight of the silage depends on the specific conditions of silaps. Approximately its mass is determined by weight of 1 m3 a month after the bookmark. Knowing the mass of 1 m3 of the silo and the volume of trenches or coarse, calculate the mass of the silo throughout the construction.

Silos cooked from cereals can be used in 12-18 days, and from legumes - in 50-90 days.

Silo quality. Silo quality requirements are given in GOST 23638-79. To evaluate its quality, a combined sample is selected by a mass of at least 2 kg.

The silage should be characterized by a well-pronounced structure of parts of plants - leaves, inflorescences, stems, to be an unhappy consistency, without ease of illegality, stale, mold, rotary and other stares.

According to chemical and organoleptic indicators, it is divided into I, II, III classes and non-class.

The eclated silage of brown and dark brown color, with a strong smell of honey or freshly baked rye

A source: General Director of SKK "Victoria-Agro", Professor Taratorkin V.M.

It is known that the content of metabolic energy in the feed is a calculated indicator defined by several most important. In this regard, we will write below about feeds with a high content of exchange energy, implying a whole complex of indicators of evaluation of feed quality.

To obtain cheap high quality feed, it is necessary:

- purchase trailed mower - air conditioning plots for rapid green mass;

- purchase rake - hike consumers, with a width of the grip twice the width of the gripping of mowers - ultrasters;

- purchase reliable and high-performance forage harvester with roller picker and herbal harvest;

- to bring in a good condition of the silo: install the slabs where they are not. Shoot cement mortar The slots between the plates, concrete - the irregularity of the bottom of the silo and damage to the entrances, seal all the joints between the bitumen plates;

- purchase a polyethylene film for pre-covering the walls of silos and shelting the rambling green mass;

- prepare a grint, for example, to collect and caring to silos old automobile and tractor tires for their use as a negle;

- cat with green masses to carry out: cereals - in the phase of exit to the tube, legumes - during the period of bootonization;

- green mass cutting length - 5 ... 6 cm.

In fig. 1 ... 6 shows examples of trailed machinery and tractor and self-propelled units to perform technological operations of the suspension workpiece.

Fig. 1. Casation of herbs for a sieney with ivy and laying of mass in the processes: Trailed mower-plot with air-conditioned grip width 3.6 m

Fig. 2. Sgshring two borders of a crumpled green mass in the roller: a rake-rod with a field copying system

Fig. 3. Self-propelled forage harvester on the selection of rolled green masses on a sieuten with grinding and loading into vehicles. Tractor trailer with rising green mass to increase body capacity

Fig. 4. Tractor type K-700 with a bulldozer hide - the best on the grinding of green mass, but the thickness of the trambly layer should be no more than 0.3 - 0.4 m, otherwise the layer is not tightly lost

Fig. 5. The rammed green mass is covered with two layers of the film, the oppression of the rift from the old car tires is placed. In the process of scenes, the "avgar" and shrinkage of the mass occurs.

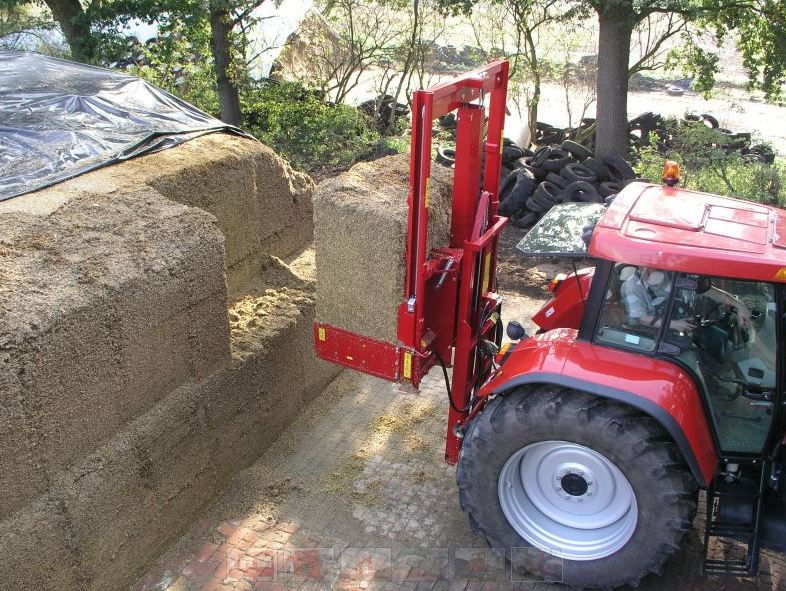

Fig. 6. Smooth cut without shaking the array of Senge - it is very important

Main indicators of food harvesting technology

When choosing and implementing the technology of the harvesting of feed, physiological requirements of animals are of great importance, the time of ukosa, the duration of the green mass, canning, a set of cultures.

Consider the physiological needs of animals

Dairy cows need a sufficient and balanced amount of fiber supplied with feed. The optimal content of the structure-forming fiber in the feed diet is especially important for the normal functioning of the digestive system. Structural efficiency of the diet. Recall that in a daily diet, a cow is needed at least 2.4 kg of structure-forming fiber. On the other hand, the fiber content in the diet should be limited, since from the point of view of physiology to chew 1 kg of fiber from coarse cow, it is necessary for 3 hours and the process of chewing cannot last a total of more than 9 hours a day. Therefore, the middle cow can eat no more than 3 kg of raw fibers per day.

In practice, we mainly encounter rations with a high content of fiber, but with a low content of exchange energy that reduce animal productivity. In addition, excess fiber reduces the absorption of nutrients and energy. An attempt to compensate for the emerging energy deficit due to an increase in the dose of concentrated feed leads to a hazardous result - displacing fiber from the diet.

The task of the livestock is to ensure the physiologically necessary amount of fiber, not allowing its displacement from the diet. It is economically expressed in reducing feed costs while simultaneously growing productivity.

Concept of production of feed

The first step towards improving the productivity and economic efficiency of animals is to increase the energy value of the main feed when optimizing the content of fiber in it. There is a pattern: the higher the level of the milk productivity of cows and the larger the share of herbal silage in the diet, the lower the fiber content should be.

To improve the quality of the basic feed, it follows using the optimal deadlines for good conditions preserving, prevent overly high fiber content and caused by insufficient absorption of metabolic energy. The ratio of mass of leaves, stems, colors and seeds, as well as chemical composition Separate fractions change in the process of growth. Therefore, the nutritional value of the green feed plant largely depends on the moment of its use. Favorable for harvesting bean grass and gracious crops Time is considered when the tissue content in a dry matter ranges from 22 to 26%. This time is usually limited to 10 days. The greatest productivity of cows can be achieved when using feed, harvested on May 20 (for the conditions of the central district of the non-black-earth zone of Russia) - the loss of potential annual Nadoy on the cow is zero.

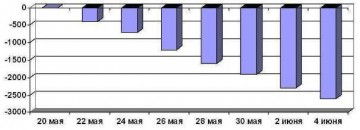

It was experimentally established that tightening the start of work for only two days, it leads, for example, to a decrease in the consumption of herbal silo by 0.5 kg of dry matter and reduce the productivity of the main diet for 2 kg of milk per day for each cow, therefore we lose 400 kg at once Every cow per year, for 10 days - 2000 kg!

In the main phase of the vegetation of the first hide, the daily increase in crude fiber is from 4 to 5 g per each kg of dry matter. At the same time, the energy value of the diet is reduced by 0.1 MJE net-energy for lactation (NEL) and, accordingly, its potential productivity is 185 kg of milk for each cow per year. Given the above, it is necessary to consider issues related to the yield, from the point of view of plant valuables. The limit productivity of feed is determined by the period of vegetation of harvested feed and the content of crude fiber in the main feed.

Fig. 7. Losses of the milk productivity of cows when tightening the timing of the harvesting of feed (example for the conditions of the central regions of Russia)

Table 1. Dependence of the quality of feed from the plant development phase

| Plants | Phase of development\u003e | Concentration of exchange energy, MJ / kg | |||

|---|---|---|---|---|---|

| Green mass | Hay 86% | Senage 35% | Herbal flour | ||

| Legumes and beans-cereal | Before the bootonization | 11,1 | - | - | 10,9 |

| Botonization | 10,5 | 9,8 | 10,8 | 10,8 | |

| Start blossom | 10,4 | 9,5 | 10,3 | 10,2 | |

| Full flowering | 9,9 | 8,7 | 9,7 | 9,9 | |

| End of blossom | 8,8 | 8,3 | 8,6 | - | |

| Seeded cereals | To cosseling | 11,6 | - | 11,3 | 10,6 |

| Start a colet | 11,6 | 10,2 | 10,6 | 10,0 | |

| Full peel | 10,4 | 9,6 | 10,0 | 9,2 | |

| End of Kick | 11,1 | 8,5 | 9,6 | - | |

| Bloom | 10,5 | 8,1 | 8,8 | - | |

| Corn | Bloom | 9,8 | - | 9,4 | - |

| Dairy ripe | 10,7 | - | 10,1 | - | |

| Milk-wax ripeness | 10,6 | - | 10,5 | - | |

| Wax ripe | 11,5 | - | 11,1 | - | |

| Otava Bobov | Before the bootonization | 10,7 | - | - | 11,3 |

| Botonization | 10,5 | 8,6 | 10,1 | 10,2 | |

| Start blossom | 9,6 | 8,2 | 9,2 | 9,5 | |

| Otava seedes Zlatkov | 30 days | 11,2 | - | - | 10,8 |

| 45 days | 10,4 | 9,0 | 9,5 | 10,0 | |

| 60 days | 9,9 | - | - | 9,6 | |

Table 2. Sugar content in feed

| Name of feed | Sugar content | |

|---|---|---|

| g / kg nv feed | % in stub | |

| Corn in the flowering phase | 16,0 | 10,0 |

| Corn phase of dairy and milk-wax ripeness | 55,0 | 18,5 |

| Corn in the phase of waxing | 30 | 9,0 |

| Timofeevka in the phase of rings | 19,0 | 6,0 |

| Wireless fire in the Phase | 26,0 | 8,0 |

| Oats in the throwing pan | 25,0 | 8,1 |

| Oats in the phase of milk ripeness | 35,0 | 11,0 |

| Peas in the phase of flowering and the formation of beans | 21,0 | 15,0 |

| Vika in the phase of flowering | 12,0-17,0 | 5,0 |

| Clover meadow in the phase of bootonization and starting bloom | 9,0-14,0 | 8,0 |

| Lucerne in the phase of bootonization and the beginning of flowering | 10,0-17,0 | 6,0 |

| Gorokha-oatmeal mixture in the phase of flowering and the formation of beans | 32,0 | 13,0 |

| Vika in the phase of | 12,0-17,0 | 5,0 |

| Vico-oatmeal in the phase of the beginning of blooming wiki and swelling oats mela | 20,0-27,0 | 9,0 |

| Oatmeal mixture in the formation phase of oats grain and pea blossom | 33,0 | 11,0 |

| Clover-thymofeteful mixture in the phase of Timofeevka | 25,0 | 3,0 |

| Clover-Tymofer mixture in the cholever flowering phase | 30,0 | 8,0 |

| Hay gracious good quality | 42,0 | 5,2 |

| Hay bean-cereal good quality | 42,0 | 5,5 |

| Hay bean-cereal bad quality | 11,0 | 1,5 |

| Hay clover-timoforichny good quality | 47,0 | 5,0 |

| Hay clover poor quality | 12,0 | 1,5 |

| Hay Lucerne High Quality | 26,0 | 3,0 |

| Hay Lucernea Bad Quality | 9,0 | 1,0 |

| Tymofeteful hay in the flowering phase | 32,0 | 4,0 |

| Silo of ordinary brewing | 1,7-3,0 | 1,0 |

| Silos from the grained herbs | 2,0-8,0 | 2,6 |

| Senage | 28,5 | 5,5 |

Table 3. Content of SV, OE and SP in Senget of cereal herbs

| Phase development | St.,% | Content in 1 kg of sv | ||||

|---|---|---|---|---|---|---|

| SZ, G. | SP, G. | SK, G. | Chell, MJ | OE, MJ | ||

| To cosseling | 35 | 114 | 187 | 220 | 6,6 | 10,8 |

| Start a colet | 35 | 111 | 168 | 258 | 6,1 | 10,2 |

| End of Kick | 35 | 113 | 150 | 290 | 5,9 | 10,0 |

| Bloom | 35 | 114 | 129 | 319 | 5,6 | 9,5 |

| After flowering | 35 | 116 | 120 | 348 | 5,2 | 8,9 |

| Otava less than 4 weeks | 35 | 132 | 192 | 214 | 6,0 | 10,0 |

| Otava 4-6 weeks | 35 | 124 | 168 | 254 | 5,7 | 9,6 |

| Otava more than 6 weeks | 35 | 112 | 150 | 295 | 5,2 | 8,9 |

Table 4. Forage value of the grain plant in the phase of the end of milk ripeness grain

| Culture | St.,% | In 1 kg of sv, g | Digestibility,% | In 1 kg of sv | |||||

|---|---|---|---|---|---|---|---|---|---|

| SZ | SP. | SC. | Organic mass | OE | RP, G. | Chell, MJ | OE, MJ | ||

| Rye | 40 | 40 | 80 | 340 | 61 | 57 | 40 | 5,1 | 8,6 |

| Wheat | 40 | 40 | 90 | 310 | 64 | 60 | 50 | 5,4 | 9,3 |

| Oats. | 40 | 70 | 80 | 310 | 63 | 59 | 40 | 5,3 | 9,1 |

| Barley | 40 | 50 | 90 | 280 | 67 | 63 | 50 | 5,7 | 9,6 |

|

Barley-cellax |

50 | 70 | 110 | 280 | 68 | 64 | 70 | 5,8 | 9,7 |

Table 5. Nutrition of corn shynaments

Green mass breakage duration

After the grinding of the green mass, the intensive processes of breathing begin, in which the easily soluble carbohydrates of the cell juice are combined (oxidized). These carbohydrates playing an important role and as power supplies for lactic acid bacteria, and as suppliers of exchange energy for animals are irrevocably lost. This process stops when the share of dry matter is reached, about 80%. With breathing, it is released 15 times more thermal energy than with ferry fermentation. Noticeable heating of the green mass in the roll or when it is stored, is the main loss indicator. The increase in the temperature of the green mass by 10 degrees reduces the energy value of the silo by about 1%. At temperatures above 50 degrees, protein destruction occurs.

The length of the cutting also has a significant effect on this process. The average fiber increases at 7, 12 and 10 g / kg of dry matter, if the cutting length is 5, 10 and 20 mm respectively.

Easy tools for cereal and legumes is mandatory, as it significantly improves their silos and reduces or completely prevent losses due to the formation of silage juice. On the other hand, the longer the bevelled mass remains in the field, the higher the loss of breathing and washing the nutrients in the event of rain. Already after 2 days of finding the miserable mass in the field, the expected loss of productivity of the main diet of animals, even under good weather conditions, reach 2 and more kg of milk on the cow per day. It is necessary to strive to ensure that the beveled green mass is not long in the field. Rapid drying of green mass is feasible due to cats with glare, turning and flaws. The early Early Equipment (for Russia) and intensive reassembly. Optimal time There is no mash in the field - less than 24 hours.

Dirt in the feed - the first enemy of the productivity of cattle

A negative effect on the quality of the Senge also has a high content of raw ash. This deteriorates the quality of the feed, the silo plant is reduced. Contaminated Senage, due to negative impact on digestion processes in the RubE, has a negative effect on the health and productivity of animals.

The permissible content of crude ashes in the Senget is no more than 80 ... 100 g per 1 kg of dry matter and, accordingly. With increasing pollution, the concentration of energy in the Senget is reduced. This is due to the effect of breeding and undesirable fermentation processes with the formation of oil acid, which are accompanied by large losses of energy.

Pollution causes mainly soil particles that fall on food when hitting the rain drops about the ground, soil units raised into the air due to wind erosion, flooding and random dust impurities during cleaning. The latter cannot be completely avoided, but you can reduce.

Pollution due to splashes from rain droplets or wind erosion depend on the degree of soil coating by plant mass. It is regulated by treatment in the process of vegetation by mesh harrow and rolling in the spring, hurdling grass, as well as the intensity of use. Dense turf with rich grass - prerequisite for unpolluted haygoing. At grounds with stains of naked soil, the risk of srench pollution rises.

Small mammals and rainworms can be thrown into the surface of the field 8 for 1 year (average number), 25 (high) or even 80 (very high) tons of land for each hectare. Lack of mice (traps, petitions for birds of prey), careless care for the turf and low slice can lead to contamination of the Senge.

Low slice (less than 5 ... 7 cm) not only favors the development of unwanted plant species, but also contributes to the formation of loose turf.

Organic fertilizers, especially when non-compliance with the technology of their introduction, can also lead to contamination of the Senaging Mass. The underlining manure and null compost must be made in winter with the subsequent sealing in the soil by the harrow. Dung Zhip. It is necessary to make small doses (less than 25 m3 per hectare) and dilute (dry matter content of about 5%) directly to the sword. It should ensure the passability of machines on the field without the formation of a gauge with an increased soil density, which increases the risk of sexual pollution.

The dung alive must be made directly to the soil, and not on vegetative plants, while the technique cutting fertilizers into the soil can have a negative effect on the turne.

Setting up cleaning machines significantly affects the contamination of the Senge. The studies have established that the lower the cutting of the plants, the higher the soil content in the Senget, and the risk of pollution increases with each of the next green mass. Squares that are predisposed to the contamination of the Senag Mass due to the high content of humus, the presence of rodents, irregularities and sections without vegetation, it is necessary to rinse with a slice height of at least 7 cm.

The use of mowers-ultrasters on dense turf does not lead to an increase in the content of raw ash in a srench. On the contrary, fast drying and, if possible, the failure of the flavor contributes to a decrease in pollution. The high dry matter content does not always mean low ash content, but, since the moisture-loving oily acid bacteria due to the growth of osmotic pressure multiplies slowly, the breaking contributes to the better quality of fermentation.

With an increase in the width of the capture with the cat, foaming and vote formation, you should pay more attention to good copying of the field surface. The width of the seizure of module modules should not exceed 3 m. Rake-vote-consumptioners and rake-foaming agents are adjusted so that the gap between the soil surface and fingers across the entire width was about 4 cm. Plighted particles of the soil and stones indicate that the mower slice is too low. Motion speed (rake-troops 5, rake-vote-consumption not more than 10 km / h) and using the supporting wheels (Multitest system) contribute to a clean and gentle turner work.

High performance should be achieved due to a larger number of cars or greater capture width, but not increasing the operating speed.

The type of harvesting technique (grass grinders, trailers, press picks) does not have a significant effect on the pollution of the green mass, if the turf dense and picks up correctly, if accurate copy is provided with the help wheels.

The condition of transport routes also affect pollution of green mass, especially in wet or dry dusty weather conditions. The entrance to the sieuzer must have a solid coating. With adverse weather conditions, it is impossible to enter the Senaskhannaya or to drive to the unloading bourge. The most favorable, from the standpoint of possible pollution, the silage of feed in the film sleeves.

Silosal additives do not reduce feed pollution, but negative phenomena in the process of fermentation are inhibited. The use of bacterial preparations that accelerate the fermentation process and overwhelmingly acid bacteria, with timely miserable and sufficient content of affordable sugar, is quite acceptable. If the mass is wet and contaminated for preserving, then preference should be given to chemical preservatives.

Every day there should be a fiber from 3 to 5 g / kg of dry matter in the field, which is significantly higher with adverse weather. Every day the delay leads to a decrease in milk productivity by 150 kg per year on a cow.

The effect of the duration of the Silo laying (time from the start of the pit bookmark to full laying, the ending of the breakdown and shelter film) is even more noticeable - the increase in fiber is up to 5 g / kg of dry matter per day or more. The time of staying on the field and bookmarks of the green mass is the main problem of the billet of feed, it should not exceed 36 ... 72 hours.

Canning feed

In the green mass, after its bookmark in the silo, various "contests" between microorganisms proceed. Whether dairy bacteria will benefit or lose, depends on the content of dry matter, sugars, the ability of the green mass to resist the decrease in pH, as well as on the number of microorganisms in the feed, the degree of contamination, mass seal and prevent air access. At the same time, the first clocks of the green mass bookmark are decisive, however, in any case, the silo or Senage cannot be better than the source green mass.

After 4 ... 6 weeks after laying a green mass, the silage or hayll ripening phase is completed, a stable state occurs. It must be remembered that even with optimal souling there is an increase in fiber content by 10 ... 15 g / kg of dry matter. An increase in fiber content by more than 3% indicates unsatisfactory scenes, which can lead to a decrease in milk productivity by 500 ... 1000 kg per cow per year.

Silo or Senage can be stored long enough without further worsening quality. However, when the silage is selected in the conditions of air access, the risk of nutrient destruction occurs. Than more square The selection and the less the density of the silo into the trench, as well as the higher the content of easily soluble carbohydrates and the longer the air access takes place, the more intense the destruction process. The formation of steam at the place of selection in the silo, at the site of intermediate storage or in the feeders, on the feed table - signs of losses.

Preservatives are used to improve the fermentation and stabilization of the Senate:

- chemicals - contribute to the development of milk-acid bacteria and suppress the development of oil and oily, mold and rot;

- biological - an additional amount of milky acidic bacteria contribute;

- supplements that help milky-sour fermentation - feed sugar, patterns, grain, ascorbic acid, yeast extraty, carbohydrate substances.

Depending on the initial raw materials, weather conditions, various preservatives or additives are used:

- for difficult plants (cereal and legumes with a dry matter content of less than 25% and sugar less than 75 g / kg of dry matter) - use chemical preservatives;

- for medium and easily-free plants with a small content of dry matter (cereal and legumes 25 ... 30% dry matter, sugar content from 75 to 100 g / kg of dry matter) - use milky-sour bacteria, plus saham-containing additives.

- for medium and easily-free plants with a large dry matter content (intensively rolling plants with a dry matter content from 28 to 40%, sugar-rich more than 100 g / kg of dry matter - corn, corn products, monocorminal hayrs in the beginning of wax ripeness) - Use milky-acid bacteria.

Structure of sowing

When developing the structure of sowing areas, preference should be preferred. The optimal mixture contains 50% alfalfa or clover, and the other 50% are cereal herbs, while the mixture may consist of many components. Preferred various varieties Rights, with the predominance of the Russian and cereal-leguminous-leguminous mixtures of the clover meadow, clover inverted with Timofeevka and Raigra. This recommendation is due to the fact that the ray of the greatest sugars content and the longest period of high metabolic energy content. The large content of sugars is very important for the occurrence of the proper preservation process of feed.

Special attention should be paid to the preparation of shenage from corn for new-product high-productive cows, bringing their volumes to a third of the planned feed. Corn Senage -Practicular type of feed, allowing to balance nitrogen content in the tab. Without corn hayll, the long-term feeding of cows with concentrated feeds with a high content of digestible protein and exchange energy without risk of accumulation of ketone bodies, therefore, without it, it is impossible to achieve high riders. Corn Senage Feed value is only when the raw materials for canning serves as a raw material with a grain of waxing 50% and above, the humidity of the crumpled raw material is 60 ... 65%. It is possible to obtain corn with cobs and grain of wax ripeness using ultra-spile hybrids, such as Hungarian selection. To achieve humidity 60 ... 65% can be harvested by corn after frosts

Senja blank technology

The norms of applying fertilizers on the active substance of elements per hectare at three cutting technology are approximately: nitrogen - 240 kg, phosphorus - 90 ... 120 kg, potassium 220 ... 280 kg, magnesium - 80 ... 100 kg.

Fertilizers are entered before each new vegetation of plants, three times per season, and 50% of the norm for the first shrew. For application mineral fertilizer Used MBU-5 spreader or similar.

The estimated deadlines for the beginning of the harvest of perennial cereal herbs into the Senage in the central regions of the country from May 20 ... June 1. You need to start the cat when the height is reached the height of the herbs is not more than 25 ... 30 cm. The principle of organization of work on the harvesting of feed is that the entire potential harvest is removed from the field not for one hide, and for 3 types, in the extreme case (with adverse weather conditions) for 2 hike.

The height of the cutting of the grass is 5 ... 7 cm, which will not allow it during the cracking of the processes in the rolls and the selection of rolls and to ensure proper process canning (achieving conditions for lactic fermentation, avoiding oil fermentation), reduce the wear of the feeding equipment (robble-vote-consuming robberies, self-propelled feed harvesters), create conditions for rapid rustling of vegetable mass of grass and decline in herbal loss from herb. The cat's cat is made by a trailed disk mower - the firm of the company "NingToday" model "Nova Kat 310 TED" or similar.

With chive, two tasks are solved: the first - plant stems break (interrupted) with a flattellite every 30 ... 50 mm, which stops the slotting in the cut plant, therefore reduces the loss of metabolic energy. The second, when the stems of the stalks of the plotters, the liquid on the surface occurs. The stiff shaft as a fan creates blowing green with air and the speeds of drying (breaking).

Be sure to break the mowing mass to moisture content of 60 ... 65%, for cereal herbs - with the use of sporing, for legumes - with turning rolls. For this, rakes are used - vote-consumptors for example, the company "Pettinger" model "Euro Top 801" or the like, if there is rainy weather, it may be necessary to take a rake - a begging for turning and peeling the green mass in the punks.

The selection of rolls with grinding is made by the "Karas" firm "Jaguar 860" with a pick-up or other similar combine (John Deer, Crown, etc.)

To ensure the safety of nutrients, it is necessary to use preservatives, such as chemical breathers, created on the basis of formic acid and offered in the Russian market of the Finnish company Kemira Agro. To uniformly introduced a preservative in the green mass, the forage harvester is equipped with a device: a bracket for installation, a plastic container with an electric pump dispenser, controlled from the cab, connecting hoses and nozzles. The preservative in a sprayed form of a dose of 4 ... 5 kg per ton of green mass is brought in the difflector of the forage harvester of the silico harness, envelops each particle of the green mass with the finest film and the levels of exchange processes associated with the loss of feed exchange energy in them. The task of the preservative to maintain the exchange energy in the stern during the period from the plant cutting in the field to its transportation to the silo, bookmarks for storage, rubbing and sealed closure of the silo polyethylene film. Next, there are other mechanisms.

The green mass is distributed over the trench by a uniform layer with a height of no more than 40 cm with a tamping of each layer (from the calculation of 2-3 travels at one place). The best on the traam is the wheel tractor K-701. It is necessary to ride during rubbing, it is necessary to go slowly so that the air manage to leave the depths of the array. To prevent the discontinuity of the monolithic mass, caustible braking tractor cannot be allowed. Good is considered to be a tamper at a density of 180 ... 200 kg / m3.

You need to lay down the trench as quickly as possible (ideally - up to 1000 tons per day) and to cover the polyethylene film after each day of laying a green mass. The edges of the film must be pre-lowered inside, along the walls of the repository (while the walls are laid out by film), the other (opposite) edges of the film are rolled over the edge of the silo and are sufficient to close the completed storage.

The green mass must be laid down along the entire length of the trench, but start from one edge, striving as quickly as possible to achieve the upper boundary. In the evening, the laid volume of the Senate, is thoroughly covered with the film, the edges of which are bent behind the edges of the silo, and put the oppression. In the morning of the next day, the film is raised and continue to lay the mass from the top edge of the coat. So daily until the whole pit is filled. Thus, the mass laying in the trench occurs not by layers, but as if by the brights that are joined in one mass.

After the trench is filled, covered with transverse canvases of the film, it is closed along the entire surface by the longitudinal canvas, carefully straighten and weld the edges of the canvases among themselves, labeled the nest. As the oppression is usually (in our country and abroad), old autotractor tires are used. The amount of tires depends on the area of \u200b\u200bthe coating of the silo - stacked one to the other without intervals. Tires put pressure on the green mass and continue to put pressure as it is precipitated, without giving air to penetrate inside.

The trench for feeding must be opened from the northern side so as to preserve the cut layer as much as possible. Senag must be taken evenly throughout the cross-sectional area of \u200b\u200bthe trench, without creating concussions of monolith, which can lead to the formation of cracks and air flow.

Well, the fence of the Senate from the pit is made with a cutter, such as a trailed or self-propelled mixer, as well as frontal loaders of the type of cheeffer, Farerene, monitor or other firms with jaw tips. Such a bucket with the help of hydraulics is whining a portion of the Senago, forming a smooth vertical section of the cross section. At the end of the fence of the Senate, the naked cut closes with a film, and so daily.

Senag must maintain its qualities before full feeding.

Features of the harvesting of corn hay

Corn cleaning should be started not in the phase of milk-wax, as it was thought before, but in the phase of waxing with the content of dry matter 35 ... 40% (humidity 60 ... 65%), Fig. 15.2. The height of the slicer of the stems is at least 40 ... 60 cm (along the bottom of the cigarette), since there are no digestible nutrients in the lower part of the stem, and, falling into the green mass, this part of the stem reduces the concentration of exchange energy in the stern array, and also pollutes Its presence of many clostridi, etc. The main energy value is not in the leaves and stems, but in the grain. Corn grain has starch, a low-shielded in the tab. In order to use the exchange energy of the grain, it is necessary to have a feed apparatus with a cutting apparatus capable of grinding leaves and stems and spurt corn grain. The most fully requirements of the workpiece of the corn haypt satisfies the firing harvester of Karas. The rest of the workpiece technology of corn haypt is the same as herbal. High-quality corn silo contains exchange energy more than 11 ... 11.5 MJ / kg of dry matter.

Fig. 8. Cathone with chopping corn with cobs and grain on the Senage after freezing and reduce the moisture content of the mass to 65 ... 70%

The quality of feed depends on personal factors and primarily on the method of their cultivation, cleaning time and the correctness of storage. It has been established that for obtaining a fishing of 20 kg when feeding cows with hay I, II, III class, the consumption of concentrated feeds per 1 kg of milk is 270, 365 and 500 g, respectively. It is explained by the fact that the feed of class III and non-schools have a rather value of 1.5-2 times lower than similar Class I feed. Feed nutrition, depending on class class, feed. units / kg

Preparation and preparation of coarse feed

Hay. The hay is the most important component of the diet to ensure full feeding in the winter period of ruminant animals (cattle and sheep). In 1 kg of hay I class I contain 0.45-0.55 feed. Units, 65-80 g of digestible protein, not less than 30 mg of carotene, as well as vitamins of group B, D, E and mineral substances. The optimal period of harvesting of beau-sharing herbs to obtain a high-quality canopy-nation phase, cereals. Finishing cleaning should be at the beginning of flowering. The vegetable mass is selected from the rolls at a humidity of 35-45%. To dry the grass is better active venting under the canopies, in sarama or directly in the skirds. For active ventilation, various fans are used (pro-cleaning from 20 to 50 thousand m3 air per hour). For one fan with a capacity of 25-30 thousand m3 per hour, the sizes of the skird are as follows: width (at the base) 5-6.5 m, height - 5.6 m, length 10-12 m.

When preparing an extruded hay, the grass after insulating is selected with a humidity of 30-35% press feeders. Press the hay is more expedient to shortened bales weighing 13-18 kg. Tubes are drying on ventilating installations. They are placed on a checker setting with a height of 3-3.5 m. The volume of the round stack is determined by the formula (0.04xp-0.012xok) of the Hochok, where the circle of the stack of stack in the oxide; Cider length; Digital indicators are constant coefficients.

For example: the length of the circumference of the stack is 10 m, the cider is 6 m; multiply 0.04 by 6 we get 0.24; 0,012 multiply by 10, we get 0.12; then 0.24-0.12 \u003d 0.12; multiply 0.12x10 \u003d 1.2; then 1.2x10 \u003d 12 m3, i.e. (0.04x6-0.12x10) x10x10

Cooking silage.

Basic silage cultures - corn, sunflower, perennial grass and pea and cereal mixtures. Optimal deadlines Cleaning for silage Corn - the end of the dairy condition and wax ripe grain, the vicor-oat mixture of the wax ripeness of the grain in the first two lower tiers of beans, sunflower, from beginning to 50% blossoms of baskets, perennial cereal grazing. For pigs and birds, silos is better to prepare the combined, which must be included in the root-tuberplods. The layout of one repository should not exceed four days. After filling the tranny and its tamper, the mass is quickly covered with a polyethylene film and a layer of earth or a peat with a thickness of 10 cm. The edges of the film must be well chosen in the form of a strip. A good silos has a pleasant smell of quashed vegetables, His humidity - 70%. It is used for feeding cows for 15-25 kg per day, pigs pork - 3-4 kg and sheep- 2.5-3 kg; It has a milk-angular effect and is considered a dietary vitamin food.

Technology of the workpiece of the Senge.

Senaging, cooked from grained up to 50-55% of the moisture of herbs. Senge use legumes - clover and alfalfa. The best deadlines for the mowing of herbs on the Senage is the bootonization for bodies and peeling for cereals. Senag has a higher nutritionality than silage, because Its humidity is 45-50%, sugar is kept in it, which is very valuable, vitamins and minerals are preserved. The presence of fiber gives the opportunity to replace in the hay diet. In addition, the Senage has a pleasant fruit smell that it distinguishes him from silage.

Sequence of a suspension workpiece: the mass is crushed and dry up to 50% humidity, it is loaded into the trenches and stacked with a layer of at least 1 m. If the trench with the height of the walls is up to 3 m, it must be loaded in three days. Mass should be well tumped. An indicator of a good seal is a massive temperature, which, with normal laying, does not rise above 370c.

After filling the trench, on the surface of the mixed mass, put a freshly cold grass with a layer of 25-30 cm and thoroughly seal it. Freshish grass lies more tight and prevents the penetration of air into the mass. To cover the Senge, like Silo, it is better to use a stabilized and light-proof film with a thickness of 0.2-0.15 cm. Senge shelter technology is similar to silo shelter.

To prevent the loss of Senate, the trench must be opened not more than 2 m lengths. Help the Senage follows daily. If the cut is not updated, after four to five days, the Senage molds and heats up to 50-550c to a depth of 1-1.5 m along the length of the trench. Called Senag You can not store more than a day. The carotein contained in it is quickly destroyed, the feed grundes and worse eats the cattle.

V. A. Yurlova, Consultant SRF

How to speed up the maturation of tomatoes?

For this plant you need to form correctly. IN middle lane Of great importance is the pausing and the caption of plants. Tomatoes have the ability to branch very much, from each kidney located in the sinus of the sheet on the main stem, grows lateral shoots. The removal of these shoots is called step-in. EU-Li plant is not pausing, there are many shoots on it and there will be floral brushes on each. What they are more, the slower the fruits are formed and ripen. Hourging not only accelerates the ripening of fruits, but also significantly increases the harvest in the first fees. Palecification of plants is necessary in areas with short-kim in summer, with thickened landings, when growing lateral varieties and, if there is strong plant growth, to the detriment of fruiting. Pasynkuya, the plant is formed in one, two and three stems. With one-stem form on the main stem, all the side shoots formed in the sinus of each sheet are removed; With two-sided- remove all side shoots, with the exception of one growing directly under the first floral brush; With a three-sieves, except the step, under the first floral brush, leave another one of the lower, but the strongest escape. Palecking the plant needs to be systematically so that the panels are long no more than 4-5 cm, leaving "penets" length 1 cm, which will delay the formation of new win-gods. Synogide flowers from the first brushes are tremended, while it is lost early yield. Sowing can be avoided by sprinkling flower decaying boric acid (1 gr per liter of water) in dry weather in the morning and in the evening.

The september is the removal of the tops in fruitless shoots to limit the growth of the plant, which will speed up the formation and aging of the proposed fruit. In the middle strip it is carried out until August 10.

Through a longitudinal cut of the stem: it is made by a length of 5-6 cm at a height of 12 cm from the soil. Sliding is inserted into the cut. The restriction of nutrition and moisture will speed up the aging of fruits.

R. A. Gorokhova, Consultant SRF

An important task of agricultural production is a harvesting of feed. The main types of food harvested are: hay, siene, silo and vitamin (herbal) flour.

There are several technologies of feed harvesting. The choice of this or that technology depends on the needs of farm, climate, weather conditions, the presence of appropriate equipment.

Harvesting hay

Consider some of the most common technologies of the suspension.1. Preparation of the scattered hay

The grass is mowed by mowers with robbles, form the rolls using a robber, collect pickers in the shields - shocks, bring to the place of discarding copanos and fierce stacking agents. In winter (in the stall period), the skid is cut by skyrrodores and in parts are brought to the farm or in the crotaces. It is also possible to grind the skin of forage grazers with loading in the vehicle.2. Preparation of pressed hay

With this technology, the grass is also mowed by midges, dried with simultaneous string with robbles, form rolls with a robber, but then the technology changes. Rolls are selected and simultaneously pressed, in the form of bales or rolls, respectively, bale or rolled preservatives. The extruded hay is transported to the storage location. In winter, rolls and bales will be dismissed in crotaces or farm.3. Preparation of the substedy hay

With this technology, the initial chain of operations remains unchanged: the grass is also mowed by mowers, dried with simultaneous stroke with robbles, form rolls using a robber, on the rolls are selected by the rims. They pick up the roller and form a stack of subpressive hay from it with a double vertex, and will be dismissed to the place of storage to the edge of the field closer to the road. In winter, another car, a hardware, will take a stack in the crotos or farm.4. Benefits and disadvantages

The most common workpiece technology until recently was a billet in the skirds - scattered hay. She repeated the operations applied during the workpiece of the hay for personal farms, not one generation of the peasants exactly and grew the hay.The advantages of this method - the technology spent over the centuries, only instead of hand-made mowers, instead of hand robber - tractor, and showers, coplings and stacking agents came to the change.

Disadvantages - a large number of operations, and therefore cars, people and time. All this leads to an increase in the cost of hay.

Applying the technology of the preparation of extruded hay, reduce the number of operations, and hence, reduce the cost of tons of hay. A method of rolled pressing is particularly effective, a rolon weighing up to 500 kilograms is obtained instead of the previous 15 - 20 bales. The use of manual labor with this technology is reduced to a minimum or absent. In addition, while the method of 2-3 times is reduced by the need for storage facilities (snowy sheds), and applying the machine for packaging the roll of polyethylene warehouse is almost no longer needed.

Disadvantages - you need to purchase a new technique.

When using the workpiece technology of the subdested hay in the second stage of the production process (the selection of the roll and the formation of a stack) use one typewriter machine, and the second harder is needed only in the stall period. But this technology has not found wide application for a number of reasons: you need to buy two cars and for greater cost.

Billet Silo

Silo is treated with bacteria, mainly lactic acid, crushed vegetable mass. Bacteria are powered by sugars, while producing milk acid. Milk acid does not give to develop putrid bacteria that decompose the mass make it unsuitable. In addition, it is necessary to deprive these bacteria oxygen, as they are dying when it is absent. After the concentration of lactic acid reaches a certain limit (about 12%), the further development of lactic acid bacteria stops. The pH level is 4.2 or more, in this case, the silo is suitable for long storage. To remove air from the mass of it, it is trambed, and after filling the silo pits, it is closed with a material that does not transmit air, for example a polyethylene film. Silos are bought from freshly accelerated mass or grained grass, humidity at least 60%. Corn, Sunflower sorghum, Sudanese grass and other herbs. The suitability of plants for silacies is not the same. The more plants contain sugars, the better they are forgotten. Sugar beet leaves contain few sugars and do not fall, but not more than 10% are added to the mass. Also, root and tuberiodes can also be added to the mass of the mass, and various vegetable waste of local industry. The process of scenes occurs faster if the mass is crushed to size 30-50 mm., We have been installed and useful bacteria is added to it. Approximate Silo Preparedness Duty 30-40 days after closing. It has a sweetly smell and yellow-straw color. Store the silo in silo pits or towers, use other storage methods, such as a mound or between two straw skirds, but in this case a greater amount of silo goes into waste, it is more difficult to ensure tightness.Preparation of herbal flour

Herbal flour is crushed and dried, at a large temperature (400 - 800 s °), in a short time (1 - 10 minutes), freshly closed or roller grass.In the harvesting of herbal flour, the grass is mounted with grinding or pick up and crushed the rolled rolls. Next, the grass is dried in special vitamin flour aggregates (AVM) and pressed the resulting mass into the granules. The short effects of high temperature quickly dries grass and does not destroy proteins and vitamins. Almost completely excluded dependence on weather conditions. The obtained granules or briquettes occupy much smaller volumes, herbal flour technologies in the process of feeding (koroto) and distribution of feed.

Disadvantages - the high cost of fuel currently does not allow to use this technology widely.

Before the start of hot pores, quite a bit of time remains. The animals are already thinking about the upcoming harvesting of feed. Now there are still time to work on the correction of errors that are available when organizing these events. After all, it says it says: the summer day feeds.

On the eve of the beginning of the season, the billets of feed is important to correctly navigate, from which crops and how to prepare high-quality feed for the winter stall period. The main criteria for which should be relying in the cultivation of feed crops and the feed laying, I would designate this way:

preparation of machinery and land, time and methods of mowing herbs, preservation and choice of preservative.

The best farms make a bet on high-quality food, as it increases dairy productivity, so the main task in preserving the silo, the Senge is to maintain quality. If the herbal food of good quality (digestibility + quality of conservation), then the cows give a sufficient amount of milk with a small proportion of concentrated feed. But, striving to harvest the planned feed volume, often come across the worsening of quality. In such a situation, balance the diet of the animal without the use of additional components, the additives are almost impossible.

The most important point in the practice of feeding is the choice of the time of harvesting of herbs, since the rations with a high content of fiber, but with a low content of exchange energy reduce the absorption of metabolic energy and, accordingly, animal productivity. Based on this, you can evaluate the main advantages of the early hide, namely: low fiber content, high metropolis content, high protein content, light digestibility, good taste quality. To preserve all the listed qualities of feed, it is necessary to clean the foaming of cereals in the phase, and for legumes in the bootonization phase. At this time, 1 kg of dry matter contains 0.86-1.0 k.ed. The main difficulty at the same time remains timely organization of the harvesting of grass, taking into account the ripening of herbag, weather conditions. With a timely organization of the first hide, it is possible to obtain not only high-quality feed, but also full feed in the second and third force. In the late stages of plant development, the dry matter content reaches 30-35%, but due to the high content of crude fiber when silence such feed will dramatically decrease their nutritionality. It is believed that lagging with herbs harvesting daily leads to a loss of 2% feed. units. In terms of milk, it will be 2-3 kg per day, and a year - from 600 kg to 1 ton from one cow, only due to the fact that they were late for 1 day.

The deadline for harvesting cultures on the silage should be no more than 10-12 days, and the vegetation phase is determined visually or by counting the plants that have entered this phase. It should always be remembered and take into account the fact that, depending on the weather conditions, the content of fiber in plants increases by 0.3-0.5% each day.

Analysis of feeding of dairy cows in the winter stopper shows that the rations are usually not balanced on protein, sugar, calcium and phosphorus from 20 to 35%. And the milk productivity of cows is limited by the rate of nutrition, which in the diet lacks the most. In such conditions, the non-cash products can reach 50%.

Billet Senge.

To achieve the optimal humidity of the feed mixture, 60-70% as the main feed is necessary for Senage from perennial herbs, one-year mixtures of herbs, corn, zerozenage. Herbs harvesting at an early stage of vegetation makes it possible to prepare the Senge with the energy value of more than 10 MJ OE in 1 kg of dry matter. At the same time, the young grass is characterized by a high level of sugars and low - fiber. The height of the cutting of the grass is 5-7 cm. This allows you to not contaminate it by the soil particles during vane and selection. By inflammatory, the dry matter content should be made in the mighty weight to 35-40%. To achieve the homogeneity of the mass of dry matter content, the drying drying is carried out in the scattered state, followed by the formation of rolls. The optimal deadlines should not exceed 24 hours. The breaking of the massive mass when the dry matter content is more than 40%, leads to insufficient density in the process of tamping. When using preservatives, their uniform distribution in the green mass is achieved by entering during the selection of rolls. Cutting length should be 25-40 mm, which provides access to bacteria to sugars of plants and a density of 180-200 kg of dry matter in a cubic meter of the Senge, as well as minimum nutritional losses and a lack of mold. The feature of the Senate tab in the trench is that the mixed mass must be continuously and thoroughly seal. The thickness of the daily laid sealing layer of the mass should be at least 1 m. Special attention should be paid to the mass seal near the walls, aligning it, tamping and forming a convex surface to ensure a good stock of rainwater, as when storing a hayague in trenches, a large amount of spoiled feed is Along the walls, top and in the ends of the repository. In order to avoid losses during storage and penetration of air, it is desirable to close the trench with a film and on top of the cargo. This contributes to the further sealing of the Senge and the holding of the film.

The first autopsy of the Senate Trench is carried out no earlier than 6-8 weeks from the beginning of the bookmark. When opening the trench, it is necessary to minimize the mass breakage and air penetration. Therefore, the recess is carried out perpendicular to the surface of the trench with a smooth layer. The daily excavation of the Senge must be calculated in such a way that there is no excessive surplus near the trench. At the same time, it should be guided by the principle: only in the fresh form - rather in the feeder.

Billet silage.

Principal differences in the Silo and Senge tab a bit. An important point is the deadline for harvesting corn on the silage, namely in the phase of the wax ripe grain. During this period, the optimal amount of dry matter accumulates in plants. The earlier make corn, the worse the quality of the silage. In early phases of vegetation, when grain formation occurs, and plants have in the dairy ripeness high humidity and excess sugar content, which is completely fermented in acid and is used by putrid bacteria. In the waxing phase, the height of the cut should be increased to 50 cm, since the lower part interferes with the absorption of other feeds. The higher the cut level, the greater the concentration of energy. It is necessary during the harvesting of silage from corn to strive for the following quality criteria: at 60-70% of the humidity and degree of grinding of 7-15 mm, the 100% compound of flattening grain contains in 100 g of dry matter more than 300 g of starch, 180-210 crude fiber, 11 , 1 MJ OE.

The use of chemical or biological preparations for canning silage, spindle grain and grain in practice has become a mandatory phase of feed harvesting. Of course, a good feed can be obtained without using preservatives, since its quality primarily depends on the quality of the feedstock (herb in case of silo) and compliance with the workpiece technology. However, refuse to apply preservatives - it means to reconcile with the loss of nutrients and fill out these losses by an increase in the share of more expensive and less physiological feed in the diet.

Georgy Laptev, Director of Biotrof LLC,

doctor of Biologic Sciences

When harvesting corn, you should also pay attention to the cutting value. In the phase of milk-wax ripe, it should be 30-35 mm, and a milk ripeness is 40-45 mm to minimize the waterion from the plant cells.

When the corn silage is layered in the trenches, the thickness of the daily laid layer of mass in the compacted form should be at least 80 cm. In the first two-three days, the preservation of the mass provides phytoncides. These discharges have strong bactericidal properties, and if the mass is placed by small layers, they will destroy, and oil acid is formed in the silo. Just like the Senage, the silage should be covered with a film using a cargo, since the storage of a non-silage is especially dangerous in spring time, after thawing the surface layer. During this period, gas exchange occurs between the silo and environmentalAs a result, the air quickly penetrates into a greater depth, causing damage to the mass.

In the practice of feeding it is not easy to consider and comply with all the subtleties and rules. Therefore, there are a number of well-known errors that lead to a deterioration in the quality of silage, which should always be remembered.

1. Late hodges. The silage is usually difficult due to the fact that the stalks of the plants are loaded and the sugar content is reduced.

2. Too low chicken herbs. It is possible to enter the ground particles and the development of oily acid bacteria.

3. Large cutting. There are difficulties when traaming.

4. Dry raw material that is difficult to rub. Optimal humidity should be about 70%.

5. Silos is badly rammed. In the green mass there is a lot of air, it is warming, mold appears.

6. Silo is poorly covered. Due to air from entering the upper layer of silage is spoiled.

7. The silo opened early. There is a strong heating of the silage mass. The process of scenes is not over.

8. When removing from a large surface, a shelter film was removed. In large quantities, air flows, the mass is heated greatly.

9. Many weeds, difficult to calm down.

10. Low productivity of technology during the workpiece.

11. The vegetable mass was converted. The billet of raw materials in rainy weather is not recommended.

The use of preservatives.

Use of preservatives gives many advantages. The quality of the roasted feed when using a preservative is better than without it (pH, acid, ammonia, microbes). Formic acid contained in silo reduces the conversion of sugars to acid, and proteins are less disintegrated into ammonia. At the same time, cows prefer the taste of feed, the ejaciousness becomes higher. From this, you can conclude that the dairy productivity of livestock and the quality of milk, the smell and the taste of milk are better, and the content of fat and protein is higher. The acidic feed prevents the growth of salmonella and leasery, which is important for animal and human health. The choice of preservatives depends on the objective assessment of the quality of fermentation feed for last years. If the quality of fermentation has deteriorated in the process of conservation, it is necessary to apply the means for souling with a directional action to improve the fermentation process. OTHER SITUATION - When SILOS showed negative properties in the process of feeding, when the mass of the mass and the formation of mold passed. In this case, to exclude this factor, use means for improving aerobic activity. And in that and in another case, it is necessary to take into account the composition of the feed herbs and the amount of dry matter. With dry matter content more than 45% all preservatives

work is ineffective. The choice and comparison of the preservative should not be a goal. It is most important to know whether these means bringing the improvement of improvement as fermentation, aerobic stability, feed feed, productivity compared to untreated silo testers.