Putchal fogenfuller Knauf Characteristics GOST. Putty gypsum. Features of the use of gypsum putty

Gypsum putty used for finishing different surfaces. The shtlock can be performed with their own hands, not inviting specialists.

A high-quality magazine has a fine-grained structure, due to this you can sharpen irregularities from 1 to 1.5 mm. If the curvature is greater, you must first twist the surface.

Characteristics of spacure

The company KNAUF produces the highest quality gypsum putty, which has in its composition polymer additives and fillers, can dry in short timeBy forming a solid and smooth film on the surface. Advantages of plaster putty:

- the use of such a mixture prevents the formation of cracks on the surface being processed;

- thanks to vapor permeability, it helps create a good microclimate;

- easy to use;

- firm enough, durable and has a long service life;

- perfectly combined with other materials;

- low expense, which is economically beneficial;

- acceptable cost.

Like any other construction material, putty Knauf has its drawbacks:

- quickly collapsing (it is possible to attribute to the pros);

- it is seriously grinding;

- not suitable for finishing wet rooms; In this case, the acrylic putty is suitable.

The maximum layer of applying putty KNAUF is not more than 3 mm. Otherwise, the surface will be uneven with influx and furrows. Gypsum putty is designed to apply a thin layer on the surface of the surface. It creates a good basis for sticking wallpaper, because the thickness of the largest fraction can be only 0.15 mm.

Knauff firm well made sure that her plaster putty dried quickly. Cannot be prepared a large number of Mixtures immediately, otherwise, in 30 minutes, the whole mass starts to stick and become unsuitable for finishing. Fast setting occurs due to plaster. It should be remembered that the container in which the solution is mixed and the tools for work must be clean. Dirt on the walls and tools accelerates the time of frozen the mixture almost 2 times.

The shelf life of a dry mixture of KNAUF - 6 months, so it is not necessary to buy it in the future.

Cooking working solutions

Before starting work with putty, it is necessary to check the shelf life. Do not use overdue material. The finished mixture, depending on how it was stirred, may have various properties.

The first rule when they knead: pour powder into the water should be slowly, distributing on the surface of the water. It is best to do it with your hands, not a trowel. It is necessary to add the mixture until the spacure level becomes slightly above the water level. After giving a mixture of 2 to 3 minutes for swelling.

Stirring is performed manually, without using the mixer. It may seem that the mixture is liquid, but it is impossible to add dry powder. A minute later, or two, everything will be improved by itself and acquire the necessary consistency.

In no case cannot be remnants from the spatula to the bucket with a working mixture. This leads to a reduction in the operation time with a solution and the formation of lumps.

Preparation for work

For putty, the following tools will be needed:

- rule;

- metal spatula;

- capacity for mixing the mixture;

- water sprayer;

- shovel or trowel.

Before buying the material, Knauf should determine the type of putty. Depending on the stage of the work done, it can be universal, starting or finishing. This is usually indicated on the package. It is necessary to explore specifications material.

To prepare the surface to work, it is necessary to remove old wallpapers, paint, clean the walls from dirt, fatty and rusty spots. If there is a mold, remove it with special means, which includes antiseptics.

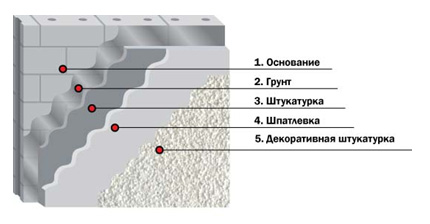

Walls need to be treated with primer, which is selected depending on the type of base. It is recommended to apply primer in 1 - 2 layers. After that, it is necessary to make a putty and proceed to work. It is important not to forget to periodically stir the composition during operation. Sometimes you can add some water so that the mixture saves the plasticity and did not frozen some time.

Do not allow the composition of the eyes or skin. If this happened, you need to rinse the affected area warm water. Work is recommended in special clothing, it is also necessary to apply the tool to protect the skin.

Application on the surface

The putty is performed using spatulas of different sizes. To a larger spatula, the portion of the mixture of KNAUF is superimposed, then it is frozen on the surface with a smooth layer. The tool is recommended to keep under a small angle relative to the surface. You can perform both horizontal and vertical movements. At the corners, the mixture is applied by an angular spatula.

On uneven surfaces it is recommended to apply 2 layers of putty Knauff. The same is recommended to do in cases where it is planned to stick by thin wallpaper. The applied layer of putty is ground, then a new one is applied. The finish putty should be applied with a thin layer of 1 - 2 mm.

The applied layer should dry out for 1 to 2 days. Next, grinding is performed for alignment of the surface with fine-grained emery paper. The final stage is to apply decorative facing material (plaster, painting, whitewashing, wallpapers, etc.).

In order to qualitatively prepare the surface to some kind of finishing work, it is necessary to align it.

This can be achieved with the help of proper shtlocking and priming. In this case, it is important to skillfully use the tools and comply with the recommendations for the implementation.

Related records:

In the process of carrying out the repair, it is possible to invest in a rather sum, and therefore you need to try to repair in such a way that he would serve a lot of years. This can be achieved through the use of putty, due to the use of which is ensured by uniform adjacent of tiles, floors, wallpaper, various decorative elementsAlso helps to get rid of cracks and cracks in which water can fall. It is for the implementation of these purposes that in most cases a gypsum putty is used.

Putty on plaster provides the ability to align any surfaces in the room and increase the level of adhesion to paint and varnish materials or construction glue.

Gypsum - a mixture, which is an excellent basis for applying decorative substances, which are made on different bases. The binding component of such a substance is gypsum, it also includes a variety of polymers and fillers that betray material elasticity and durability. Application dry mixture must be mixed with water until the formation of a homogeneous mass. The prepared solution can be used for forty minutes, although it fully solidifies after three hours. In the process repair workEach layer applied with plaster should dry at least two hours.

Putty on a plaster basis are used for such surfaces, brickwork, Concrete, plaster, natural stone, plasterboard sheets and others. Surfaces that strongly absorb moisture, before applying gypsum putty, it is necessary to primitive. If this is not done, it will take place, and the perfectly smooth surface will not work. Through the use of primer, putty decreases and its grip with the surface is increased.

Most often, the repair work is used for repair work, which is used to complete the coating and before starting decorative work. The finishing layer of the finish gypsum after drying is obtained by white, excellently smooth and shows a high level of adhesion to the tile glue. Gypsum putty finish is used in rooms with continuous heating in cold pores and with a normal level of humidity.

The most popular manufacturers of gypsum putty are rocks and company prospectors.

The cliff putty gypsum is produced by the famous company TD Skal Trejd, which, besides the release of its products, is implemented by building materials of other companies.

Rock putty plaster is used in rooms, the level of humidity in which is at an optimal level. This building material is enhanced by cellulose, which contributes to its better solidification. The only disadvantage of the rope putty gypsum can be considered the inadmissibility of its use in the room, where the level of humidity is increased, as well as in the cold time, the goal in those rooms that are not heated.

After applying the rock, the putty gypsum surfaces are obtained white and perfectly smooth.

Very convenient in use are gypsum putties prospectors. In the construction market, they can be found packaged in buckets or in waterproof bags.

For the preparation of the finished solution of gypsum putty, the prospectors need a dry mixture to mix with water in the proportions specified in the instructions on the package, until the formation of a homogeneous mass. Such a solution is needed within three hours.

Gypsum putty prospectors due to the fact that it includes an environmentally friendly material, is safe for ambient and human health.

The consumption of plaster putty depends on the thickness of the applied layer, and is approximately one and a half kilograms per square meter.

Gypsum putty, which is rather not high, is used by many professional builders for repair work in various premises.

Gypsum putty: Application / OOO Arnad / Novosibirsk

Puttiles belong to the most, perhaps, the diverse type of building materials. They are designed to carry out a finishing finish, align the ceilings and walls before starting or sticking on them.

Scope of application of putty

Gypsum putty is used to align various defects on the surface, such as cracks, seams and large recesses. Also with its help produce a solid putty from different materials: Gypsum plates, light concrete, brick, as well as other surfaces.

Composition of wipelovka

The mixture for alignment includes plaster, mixed with a mineral plasticizer and a complex of modifying additives.

Preparation of the surface to handling putty

The surface that is treated should be in advance is cleared of contaminants, as well as fat and oils, it should also be solid and dry. If the surface refers to absorbent, before processing it must be projected.

Applying putty

On the base, the plaster putty is applied using a staple of rubber or steel, it is possible to use a steel line - the main thing so that the tool is well smoothed the surface. The dried putty, if necessary, can be treated with abrasive materials and any type of coatings, glue over it or lay it. ceramic tiles.

Storage putty

The mixture for putty can be stored in a dry room for six months. After it is better not to use, since the gypsum putty can lose its properties, and the quality of the coating will become unsatisfactory.

Get wipeluk

Contact Arnada. Our experts will advise you, what brand putty better suitable For your purposes, the quality of our building materials will ensure the reliability and durability of your construction.

Universal plaster spacure

The proportions of the mixture of 0.30-0.34 l of water per 1 kg of a mixture0.90 - 1.02 liters of water for 3 kg of mixture

1.50-1.70 l of water by 5 kg of mix

3.00-3.40 l of water by 10 kg of mixture

7.50-8.50 l of water by 25 kg of mixture Solution

used to use 1.5 hours open time of operation about 15 minutes. Adhesion minima. 0.50 MPa Cooking temperature + 5 ° C to + 25 ° C The base temperature and the surrounding is + 5 ° C to + 25 ° C thickness in dry state. 1.1 g / cm³ Max. One layer thickness2 mm

Finish putty gypsum bolars, finishing putty. Finishing materials BOLARS.

Putty is used for and external work. Aligning compositions are used for sealing large cracks and surface preparation under decorative finish. Putclone plaster, cement or used in rooms with increased and normal humidity. To prepare the base to paint use the finish putty. It hides small defects, forming a smooth surface. For external surfaces of buildings, facade putty are used. They withstand the temperature differences and atmospheric influences. TM putty is applied on the surface of concrete, brick, stone, aerated concrete and plaster.

Advantages of putty

- elasticity,

- moisture resistance

- economy

- frost resistance

- sanitation.

Application technology

The processed surface is cleaned from dust, oils, paint and moisture residues. The finish putty is applied with a metal spatula at an angle of 30-35 ° C. It is distributed over a layer surface from 0.2 to 3 mm. The finishing putty is aligned with a smooth or grater. If necessary, applied the second layer. With a layer thickness of the applied solution of 1 mm, the mixture consumption is 1 kg / cm2.

Types of wipelok

According to the astringent substance, putty are separated:

- cement. Puttles are made on the basis of white or gray cement with the addition of sand. Designed to finish non-deformable grounds ( concrete walls or facades of buildings) and surface preparation for staining or pasting with wallpaper. The catalog presents the wrathole of the Bolls (based on white cement), and the bore facade finish (based on white cement), Bolls Universal, Bollox leveling, waterproof Boll.

- gypsum. The basis is plaster and modifying polymer additives. It is used to finish the walls and ceilings, for alignment or joints of GLC with cut or semicircular edges. Gypsum putty is used for the final decoration of ceilings and walls. It belongs to it "Bolls Gypsum (White)", "Bolls Gypsum Elastic (White)" and "Bolls of Hypsil (White)";

- polymer. It is produced on a mineral basis with polymer additives and marble flour. Finishing putty applied to internal and outdoor decorationElimination of microcracks. The catalog contains putty "Bolls Finish (Belaya)", "Bolls Universal (gray)" Bolls Imperia, and Bolls Imperia-Fasade.

The scope of application is distinguished by putty:

- universal. For the main and finishing alignment of surfaces in order to eliminate irregularities and microcracks;

- aligning. For basic base equalization;

- finish. For the final alignment, the thickness of the applied layer is 0.2-3 mm;

Get additional consultation and order cement, polymer or gypsum you can use the form feedback or free hotline telephone 8-800-100-71-17.

Technical characteristics of putty fuegenfuller and its advantages make it possible to spend not only finishing work, and restoration.

1. Putchal fogenfuller is a powder white color.

2. Bending strength is 2.6 MPa.

3. The amount of compression strength is 5 MPa.

4. It is possible to work with a finished solution. You can maximize one hour.

Preparation of mortar mixes

To lave a dry mixture, use water from drinking water supply. Ratio of mixing: 1 kg of dry spacing mixture requires 0.34 - 0.40 liters of water. Dry mixture to fall asleep in a predetermined amount of water room temperature and mix for 2-3 minutes using an electromyxer or an electric drill with a nozzle, with a speed of no more than 600 rpm, until a homogeneous consistency is obtained. Give a mortar mixture to stand for 5 minutes and re-mix. With re-stirring, the addition of water is allowed to the maximum value of the above ratio. The time of using the finished mortar mixture of no more than 2 hours.

Operating procedure

Products are allowed to use in all types of civil engineering (AEF

Spacel fugenfuller

Putty for seams Fugenfuller (Fugeenfuller) Prepared on the basis of the gypsum and in combination with the reinforcing ribbon is intended for sealing the seams formed by plasterboard sheets (GLC) with drunken or semi-round and thin edges, using the reinforcing tape (this is the difference from the plaster replacement of the unifotter); Inserting cracks on them and other defects, for gluing to a smooth surface of plasterboard sheets and combined panels, for sealing seams, sinks and irregularities of concrete elements, for gluing and putting the gypsum elements.

Application:

Gypsum shovel fogenfuller is ideal for thin-layer putty concrete bases and previously launched surfaces, to fill and align the joints of the prefabricated elements from concrete, the installation of PGP, gypsum blocks.

Planfufüller putty is suitable for gluing to smooth bases of sheets or gypsum panels. Epugenfueller is used as a gluing material for any gypsum products.

Putclock fugenfuller is made on the basis of plaster and is used exclusively for work.

Preparation of the solution:

To prepare a solution of putty fugenfuller, you need to fall asleep dry mixture into a container with a cold clean water, evenly distributing it on the surface before the appearance of "dry islets" (the maximum of 2.5 kg per 1.9 liters). Then it is necessary to give a mixture to wet 2-3 minutes, and mix the spatula to the cell to obtain a homogeneous creamy consistency. After that, the addition of a dry mixture is not allowed. Use pure containers and tools.

No other components can be added to the solution, it worsens the properties of putty. It is also not allowed to add water to the thickened solution - this does not restore the source properties, and worsens them. The thickened solution is no longer suitable for work. Working hours (before the start of thickening) is at least 30 minutes, but the contamination of the dishes or tools can lead to a faster frozen

CONSUMPTION RATE:

For sealing seams per 1 m2 of mounted plasterboard sheets, there are about 250 g of dry material.

Preparation of the surface:

The preparation of the surface for the putty is carried out in the following order. Plasterboard sheets should be firmly mounted on a carrier frame or other base. The surface intended for the shtlock should be dry and cleaned from dust.

The surface itself should not be cold (at least + 10 degrees).

If there are polishes - they must be removed, it is possible to wash off (after that it is good to dry), with remove the residues of the formwork lubricant. The joints of the drywall, which will be putty and the surfaces of the sheets must be cleaned of dust with dry methods. Surfaces that strongly absorb moisture must first be projected with a brush, roller or sprayer. If the surface is smooth or concrete, it should be processed primer Knauf Betokontakt, This is necessary to increase adhesion. After applying the soil, it is impossible to get dust to the prepared surface.

In order to putchaw Knauf Fougauller It behaved well and did not form all sorts of defects and cracks during operation, all work must be carried out at the same temperature and humid mode, which will be during operation. This precaution is needed to avoid linear deformations from changing the temperature and saturation of moisture.

OPERATING PROCEDURE:

Time from the moment of backfilling the putty fugenfuller in the water before the start of the setting is about 30 minutes. Dirty tanks and tools reduce this time. Works should be made when there will be no significant change in the temperature and humidity regime in the room, which eliminates any linear changes in plasterboard sheets. The minimum temperature of the base and indoors during the work - + 10 ° C. If the indoor contains a device of a bulk or asphalt floor, then the putty should be carried out after laying the floor.

To put off the joints of the GLC (putty the usual seam), it is necessary to apply the first layer on the seam area, then the reinforcing tape is placed by pressing the spatula (it is impossible to form bubbles or chances). This layer should be given time to dry, after apply the leveling layer. Most conveniently, these manipulations make a spatula with a width of about 150 mm with a handle adapted to screw the screws. This will allow you to quickly eliminate the installation defects of plasterboard.

The solid putty of surfaces is also carried out in two stages. The first layer of a wide spatula is applied, and after drying it is applied a thinner aligning layer of putty Knauf Fougaurfuller.

After drying the second layer, the surface is adjusted using a grinding tool (grated with grinding grid). If the surface is prepared under painting, then for high-quality painting it is necessary to apply a layer of finishing putty on the finished surface.

Before applying decorative coating (paint, wallpaper, decorative stucco) surface is processed primer Knauf Tifengrund.

In order for all work to spend quickly and efficiently, you will need such tool:- Puttlefish box for the preparation of a rope solution;

Metalic chapel Metalic for kneading Knauf Fougufuller;

Metalic spatula (152 mm width);

Metalic spatula wide (200h300 mm width);

Metal spatula for external and internal angles;

The grater with a grinding grid for grinding dry sharpled surface.

All tools must be made of stainless materials. After completion of the works, the remnants of the putty Knauf Fougauller must be washed off with water.

SPECIFICATIONS:

1. layer up to 5 mm;

2. The size of the fraction is not more than 0.15 mm;

3. The output of a solution of 1 kg of a mixture of 1.3 l;

4. Compressive strength 5.2 MPa

5. Bending strength of 2.7 MPa.

STORAGE:

Bags stored in a dry room on: pallets. Material in damaged bags to use first. Shelf life - 6 months.

The plaster powder is a powder or pasty material, the basis of which is plaster. This finishing material is used to align the surfaces that are previously prepared with plaster mixtures and are projected. This building material is very popular, since the gypsum is an environmentally friendly product, and the demonstrated putty indicators are quite high.

The technical characteristics of such a putty make it possible for it quite well to pass the air, which allows it to apply it indoors for internal work. The material is perfectly combined with plaster stucco, plasterboard plates, and is also widely used on wooden, cement and concrete surfaces.

The advantages of putty plaster

Due to the fact that polymer additives are correctly combined in the recipe and other fillers can create a truly reliable and high-quality putty. It very quickly dries and a smooth and durable film is formed on the surface, which reduces the subsequent consumption of facing materials. In addition, natural environmental components that are part of this putty provide it with the following technical characteristics:

1. Park permeability, as well as the ability to create a good microclimate.

2. crack resistance, because the mixture has a sufficient level of plasticity.

3. No breaks on the surface, simplicity of application and grinding.

4. High hardness, strength and durability.

5. Diverse scope of application. It is used for, cracks, alignment, and the like.

6. Excellent adhesion with many materials. Adhesion can be strengthened by applying primer, which will also prevent conflict between materials.

7. Sanitation.

8. Ecology.

9. Available cost.

Among the main disadvantages it should be noted the impossibility of using this putty in wet premises. In most cases, it is used inside buildings and structures.

Preparation of materials and surfaces before applying putty

The following materials may be required during the work:

1. Metal spatula;

2. To stir the mixture of a drill with a mixer;

3. Tara for putty;

4. Water sprinkler to moisten the surface;

5. The blade to remove the past coating.

In the process of shtlocking, it is important to comply with security measures so that the composition does not fall into the skin and eyes. If this happened, it should be thoroughly rinsed with warm water. It is recommended to carry out work in specialized clothes, because during the work, it will definitely get a building mixture.

Putty plaster can be different types:

1. Putclone plaster universal;

2. Starting putty;

3. Putchaw finish.

The starting option is suitable for plastering mixtures, because the assignment of putty lies in the finishing alignment. Then the putty is used mainly for alignment, and then smuggling plasters and surfaces.

The universal gypsum mixture is used to seal the joints of the drywall, the shtocking of cracks. With the help of it, you can glue the GLC to the surface, and it can also be handled the combined panels.

The finishing putty is used to create a clean thin-layer alignment of flat surfaces, it is perfectly combined with the materials of the plastering layer.

Each of them is selected depending on the work. In order not to get confused, there are all the information on the packaging of the putty, including the characteristics.

However, before applying any of them, a thoroughly prepare the basis. If this is not done, then cracks will appear on the coating. First of all, you should remove the old coating ( decorative plaster, paint, paper wallpaper etc). Then it is necessary to eliminate the dirt, stains of rust and fat. If there was a mold, it is also eliminated. In stores today sell various compositions that allow them to remove them.

Then the walls are processed by the appropriate primer. It is selected under a certain type of foundation. The primer is applied in 1-2 layers. The mixture is then prepared for - dilute 1 kg of composition with 0.5 liters of water. Everyone is thoroughly mixed. Then leave 5 minutes and mix again. The resulting mixture will need to be spent in the next 2 hours. In the process of work, the composition is stirred, sometimes add water to eliminate drying and storing plasticity.

It is advisable to apply proven formulations that have proven the proven among buyers, for example, putty gypsum Fugeen Gips, Knauf, Primer and others.

1. The mixture on the wall will be applied using a spatula. The tool is kept to the surface at some angle. Press on the base with a spatula and smear putty. Movements must be both vertical and horizontal. If the walls have many irregularities and defects, then 2 layers of the mixture should be applied.

2. At the next stage, you need to put a putty gypsum finish. The mixture is prepared according to the specified recipe. The finish putty is applied by a thin layer (1-2 mm).

3. The coating must dry over a certain time. On average, 1-2 days will need.

4. Mandatory then the grinding is performed. It is necessary to make the coating alignment. For this apply sandpaper. It is advisable to use fine-grained sandpaper.

5. At the last stage, decorative facing material should be applied. Among them can be: wallpaper, plaster, whitewash, paint and the like. If the above works were produced in accordance with the instructions and most correctly, then facing materials Will hold securely and long.

Also

For painting of walls or sticking wallpaper, a perfectly smooth surface is needed. Without it, it will not be possible to ensure reliable adhesion between heterogeneous materials. For leveling of surfaces, start-up or finishing gypsum putty can be used, which will be discussed in this article.

Characteristics of gypsum wipelok

The powdered or pasty mixture based on the gypsum is a gypsum putty. In the best putty turns on not just plaster, but a snow-white gypsum (as, for example, in the Turkish brand "ASB" or German "Knauf"). However, in reality in most modern Marks Putty (especially Russian) contains gypsum with a yellowish tint.

Also, the composition of gypsum mixtures includes various modifiers (polymers) and mineral fillers (quartz sand, marble flour, etc.). Additives give putty all kinds of additional qualities. For example, mineral fillers, thanks to their small fractions, allow putting a thin layer to putty. Especially the thin layer can be achieved if there are marble particles as part of the putty. Some additives provide protection of material from humidity or contain an antiseptic, which prevents the development of mold and fungus. Also modifiers accelerate drying, prevent cracking and swallowing material.

Note! The separation of putty compositions on the starting and finishing is largely determined by the size of the filler fractions.

A more accurate definition of starting putty - "plaster mixtures". The fact is that main function Starting Compositions - Alignment of large defects. The main difference of the actual putty from plaster compositions consists in this case in the amount of defects: the plaster is designed to remove more notable flaws. But the finish putty are used for the "fine refractory" of the surface to the perfect state.

Universal gypsum compositions are also available, which are used both for starting and finish surface treatment. In such mixtures, the size of the filler fractions is minimal, but the layer applied to the surface is rather thick. Universality has rolossover: Such formulations are slightly worse than traditional starting putty and a little worse than traditional finish. In addition, universal mixtures are quite expensive. Most often, universal putty are used to lubricate the jacks between plasterboard plates, as well as to eliminate defects on plastered concrete.

Advantages of gypsum compositions

The advantages of plaster include the following characteristics:

- Gypsum coatings are ideal for residential premises, since neither in the process of application, nor during operation plaster does not highlight dangerous to health substances.

- Due to high hygroscopicity, the material absorbs excessive moisture from the environment, and with low humidity returns it back. This quality is advantageous for the premises, but absolutely eliminates the use of gypsum for processing facades.

- Gypsum putty can be applied to a wide variety of types of materials - from drywall to concrete or brick.

- Gypsum solutions are distinguished by excellent adhesion with other types of surfaces.

- Since plaster mixes contain plasticizers and modifiers, they are not cracking after drying. The coating is characterized by stability - it does not sit down and does not peel.

- Consumption of plaster powders three times lower than cement compositions. This circumstance reduces labor costs and financial expenses.

- Gypsum is easily leaving the conversion grinding.

Note! Despite the advantages described above, there has gypsum and a significant disadvantage - incompatibility with a wet environment. Consequently, in the bathrooms or kitchens to use this material it is impossible.

Comparison of gypsum with polymers

As competitors, polymer putty are most often called plaster compositions. Below will compare the performance of these mixtures:

- Both species of putty are designed for shtpocking inner parts of buildings.

- Both the other type of spacion mixtures effectively levels flawed surfaces.

- The polymer compositions are much more moisture resistant than gypsum. However, moisture resistance has the opposite direction: the material delays moisture indoors, which violates the microclimate. Gypsum coatings although not so moisture resistant, but much more vapor permeable.

- Gypsum is considered a more plastic material in comparison with polymers. Due to elasticity, the surface is less susceptible to cracking.

- If plaster - ecologically safe MaterialThe polymers are produced as a result of complex chemical processes and contain non-safe synthetic components in themselves.

- Gypsum putty are much cheaper than polymeric.

Gypsum putty "Knauf"

One of the most famous manufacturers in the world of building mixtures is the German company "Knauf". The manufacturer from Germany offers many types of putty compositions, including gypsum. The brand "Knauf Fugen" manufactures a new generation gypsum putty. This mixture is considered one of the best in its class.

Technical characteristics of the mixture

Three varieties of "Knauf Fugen" are produced:

- Standard putty "Fugen".

- A mixture of "Fugen GF", designed specifically for plastering gypsum.

- Putty for moisture-resistant plasterboard sheets called Fugen Hydro.

All three of these mixtures are produced in a powdery form and are conglomerates in which the main element is gypsum, as well as plasticizers and modifiers. In a mixture "Fugen GF" and "Fugeen Hydro" added special substances that correspond to their special tasks. For example, "Fugeen Hydro" there are additives that enhance the hydrophobic quality of the composition.

Advantages and disadvantages

The advantages of spacure mixtures "KNAUF" include the following characteristics:

- Full environmental safety, because there are no chemicals in the composition.

- The putty forms a high-strength coating, which is especially important if we are talking about restoration works on drywall or when installing protective corners.

- On the smooth surfaces, the mixture is spent very economically.

- On the treated surface, the wallpaper can be glued or apply paint layers.

- Despite the high fame of the brand, Knauf Fugen is distinguished by competitive prices.

- "Knauf" offers its goods in packing of different weights (5.10 or 25 kilograms), which is very convenient for builders.

Below are the main technical characteristics of the plate mixes mentioned above:

- The recommended layer thickness for the standard mixture "KNAUF FUGEN" ranges between 1 and 3 millimeters. For Knauf GF and Knauf Hydro, the specified parameter can range from 1 to 5 millimeters.

- The consumption of the material in the case of continuous surface treatment and at a millimeter layer is for the standard Knauf Fugen and Fugen Hydro 0.8 kilogram on square meterAnd for Fugen GF - 1.2 kilogram per square meter.

- In the case of sealing of plasterboard seams, KNAUF GF consumption is somewhat less and is about 0.3-0.5 kilograms per square meter. As for the two other gypsum blends, their flow is even less - 0.25 kilograms per square meter.

- In all three mixtures, fillers are used with the same fraction size (0.15 millimeters in diameter).

- Solutions have identical bending strength, which equals 1.56 MPa.

- Compression strength indicator - 3 MPa.

With all the numerous advantages of Knauf Fugen's spacure compositions, there are also disadvantages:

- The solution dries very quickly, forming a durable coating.

- The second drawback is a consequence of the first: a solid coating is difficult to grind. For sandpaper, the abrasive grid is needed at number 100, as well as a lot of physical effort.

- Features of the solution are such that create a layer, which would be thicker than 3 millimeters, is very difficult.

- There is a big risk of dark spots on a spacious coating. If you beat the light wallpaper from above, these spots will be noticeable.

Note! The last drawback will be equitably attributed to the unfortunate choice by the builders of the color of the spacious mixture than on Knauf. The mixtures are offered not only gray, but also white, as well as pink colors.

Scope of application "Knauf Fugen"

Washing mixtures "Fugen" are most often used in the finishing finish of dry heated rooms. The main tasks that are performed using putty are:

- hiding small base defects;

- the molding of the joints between the sheets of plasterboard with the roasted edges (the reinforcing tape is used for compression);

- finishing concrete or plaster with a thin layer of putty;

- hiding joints between the puzzle structures produced from plasterboard sheets;

- gluing on a flat surface of plasterboard sheets and a compound of various elements of plaster;

- in the case of "FUGEN HYDRO" - finish finish Waterproof and fire-resistant plasterboard sheets.

Note! Putty on a plaster basis can be used for many, but not far for all types of surfaces. The list of exceptions includes chipboard, ceramics and stone.

Preparation of a mixture "Knauf Fugen"

Before use, we break the gypsum mixture. This operation is not particularly difficult, but still it will be necessary to comply with a certain technological procedure:

- Dry powdered composition is slowly falling asleep into water tank. I do not fall asleep in one place, but evenly over the entire surface. There will take 800 grams of water on a kilogram of dry mixture.

- To the mixture evenly distributed on the liquid, it is recommended to fall asleep the powder not from the construction workshop, but from the palm.

- We fall asleep powder until the substance is higher than the fluid level.

- Leave the solution for a few minutes so that the powder is well soaked in moisture.

- Next, stir the solution. It is possible to do this manually or use a mixer running on small revolutions.

- When stirring, it should be borne in mind that the consistency of the solution initially may seem liquid. This circumstance should not be misled - no additional amount of mixture is added to the solution. After some time, the solution naturally thickens to the desired consistency.

Note! The container for the solution and the toolkit used during its preparation must be absolutely clean. Otherwise, dirt and other extraneous inclusions will spoil the quality of the coating and accelerate its grasp.

Since the working parameters of the solution are saved only for 30-40 minutes, it is necessary to prepare a solution for specific needs, and not about the reserve. The fact is that it is no longer possible to restore the necessary consistency with the addition of water and thorough stirring will not succeed.

Preparation of the foundation

Before tapping, it is necessary to carefully clean the base from garbage, dust and oil spots. You can use a vacuum cleaner for cleaning.

If we neglect the preparatory activities, cracked will certainly appear on the coating. Silvering may occur for other reasons: for example, as a result of incorrect kneading or with a lack of water in solution.

When the base is predicted, we spit all the hats of self-tapping screws and joints between the material (if it comes to plasterboard). Next, give putty dry. When the coating is dry, we clean the spacious sections with sandpaper.

Instructions for shtclovania

Initially, we mix the solution in accordance with the instructions above. It should be noted that all manufacturers offer their own recommendations for creating a working mixture. Place such instructions on the package.

Using gypsum putty for various surfaces

Using gypsum putty for various surfaces To apply the first layer of putty, we use a metal spatula. At the same time, hold the tool at some angle to the surface. We press the spatula to the surface, evenly spreading the putty on the material being processed.

To prepare the wall under the wallpaper, a pair of layers of leveling mixture are enough. If we are talking about the preparation of the surface under painting, you will need three, or even four layers of putty.

After applying the starting lineup, we drag the surface and apply the finish putty. After the finish putty, we carry out another grout, with which we remove the remaining minor coating defects.