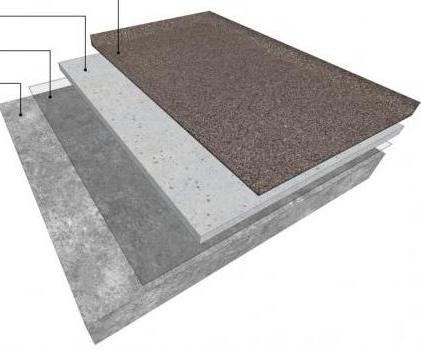

Paul with minimal screed thickness. Minimal tie thickness

Reflecting on what should be the thickness of the floor screed, you must take into account many factors. It should not be assumed that the more impressive thickness will make it possible to make the design better. This sins many homemade masters who do not have the relevant experience. In practice, it turns out that the final strength of the fill is not in all cases depends on the thickness, because the process of drying can go incorrectly, for example, it will last several months, in this case the screed will not reach of the desired characteristics. In order to achieve the desired result, it is necessary to make an accurate calculation.

Optimal thickness

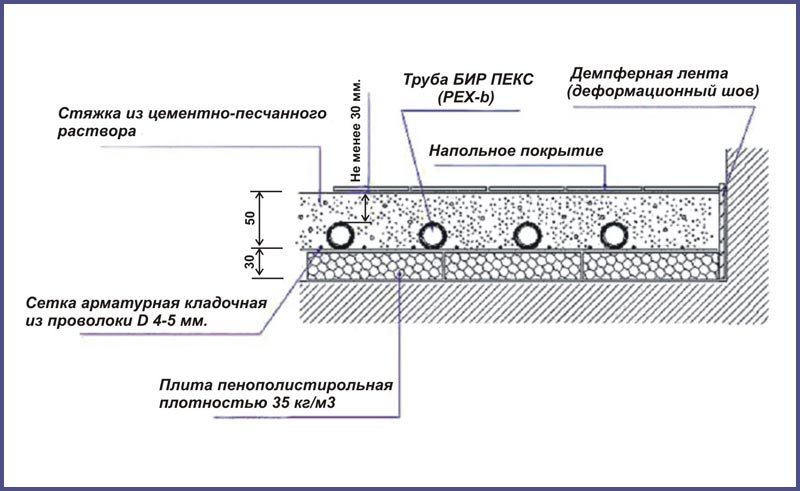

Floor alignment is a rather important process, they are neglected very rarely. This is especially true for residential premises. As an exception, laying the finishing coverage on the lags. The thickness of the floor screed for the heated system will differ from the usual 40mm fill. If you plan to put water pipes, then you will need 70-mm reservoirs, but the thickness of the screed in this case should not be more than 100 mm. If we are talking about electric source Heat, it can be hidden under concrete, the height of which will be 5 cm or less.

After the fill, the solution cannot be warm up using the launch of a warm floor, because the strength of the screed will be reduced. As a basis for these figures, the requirements for the strength of the fill. Experts recommend managing more accurate screed parameters. Thus, the thickness of the screed over the water warm floor can be equal to the limit of 7 to 10 cm. As for the electrical system for heating, the thickness can be equal to 3-5 cm.

For reference

The time of frosting the largest thickness can reach 140 days. The system must be pre-verified for integrity and performance. This is especially true of water floors. The system starts once again closer to the completion of the hardening process so that moisture residues in the depth of concrete were completely dried.

Minimum tie height

If you are guided by sanitary standards and rules, then in residential premises, a solution of 40 mm layer and above should be poured. This indicator is minimal. But in some cases, the formation of a thinner layer is allowed. This can be attributed to the low activity of the room operation, as for the utility and storerooms, because their visit is carried out very rarely.

If the thickness of the floor screed is less than 30 mm, the material strength may be insufficient in unforeseen situations. This concerns the falls of massive items. From this it should be concluded that minimum height limited to a parameter of 35 mm.

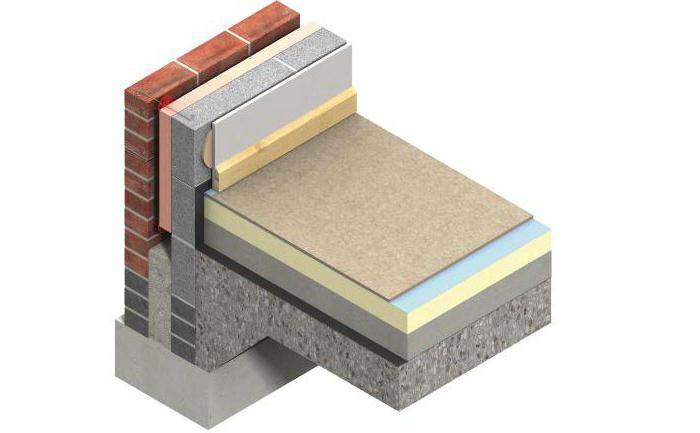

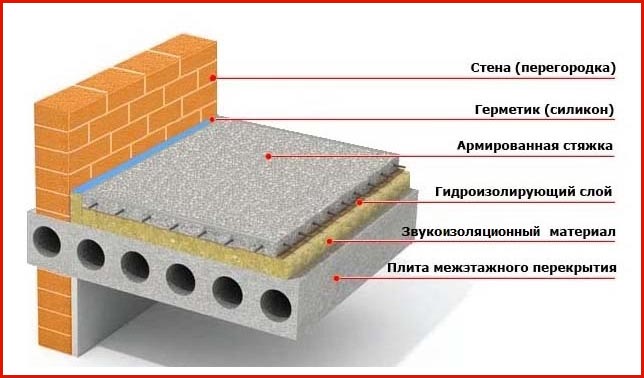

It is important to pay attention to the exceptions. If there is a goal to increase the heat and sound insulation quality of overlapping on an uneven base, you should form a submission for an easy screed. On the irregularity of the plate, the solution is poured, the thickness of which will be 2 cm. After drying the material, the insulation or sound insulation is laid on top, then the separation of the thin film goes. At the final stage, the solution of the calculated thickness is poured to ensure normal strength.

Features of determining the thickness of the screed

Before you have defined the thickness of the floor screed, you must decide under what conditions the room will be operated. Therefore, to some extent you can determine the operational load on the surface. For example, public rooms by type of vestibules, corridors, kitchens and living rooms require a significant layer thickness in 70 mm or higher or reinforcement, with which the height of the formation can be reduced to 40 mm.

If we are talking about a children's room, which will combine gaming space, it is important to achieve impressive coating strength. The thickness of the screed in this case should be 50 mm. If we take into account the aforementioned approximate parameters, the question of what is the maximum thickness of the floor screed for the entire apartment. Answer this question should be unambiguously - the height of the layer should be the same everywhere.

In some cases, the difference in heights between the premises or within one space is created artificially, however, this option cannot be called the easiest. If you equip a warm floor system or want to achieve high base strength for the finishing coating, then you should dwell on a thickness ranging from 50 to 60 mm. This will be enough, which is especially relevant for the reinforcing layer. For calculations, the guidelines must be played. After all, if it is strongly lifted by the floor, taking into account the finishing coating, you can reduce them in the height, which will assume the need to install door flaps of unusual sizes.

Additionally, the minimum screed thickness parameters

Some experts believe that there is no optimal thickness of the floor screed in the apartment. This belief is based on the fact that the mentioned parameter will depend on several factors immediately, among them:

- a variety of overlap;

- soil type;

- purpose of the room.

All these conditions affect not only the ultimate thickness indicator, but also on:

- cost of work;

- type of used reinforcing mesh;

- selection of cement brand.

Based on the height of the concrete layer, it can be argued that the screed may have the following varieties of thickness:

- minimum;

- average;

- maximum.

The minimum thickness sometimes reaches 20 mm. This type of coating can be equipped without the use of reinforcement, but only in the case when self-leveling mixtures are used for work. The average thickness reaches 70 mm. In this case, fittings or reinforced grid should be activated. The maximum thickness reaches 150 mm. At the same time, the screed has a type of monolithic design with reinforcement. This option for a private house can be sex and foundation that is combined into a single system.

Thickness will depend on the materials you intend to use during system arrangement. For example, a minimum thickness can have a layer of concrete with adding rubble. For thin screeds, the most suitable choice is self-leveling mixtures for the finishing floor design. At the final stage, such a surface is covered with decorative material. With the help of such technology, it is possible to form the formation of a perfectly even laughing layer, after drying the materials of which can be started at the installation of decorative coating.

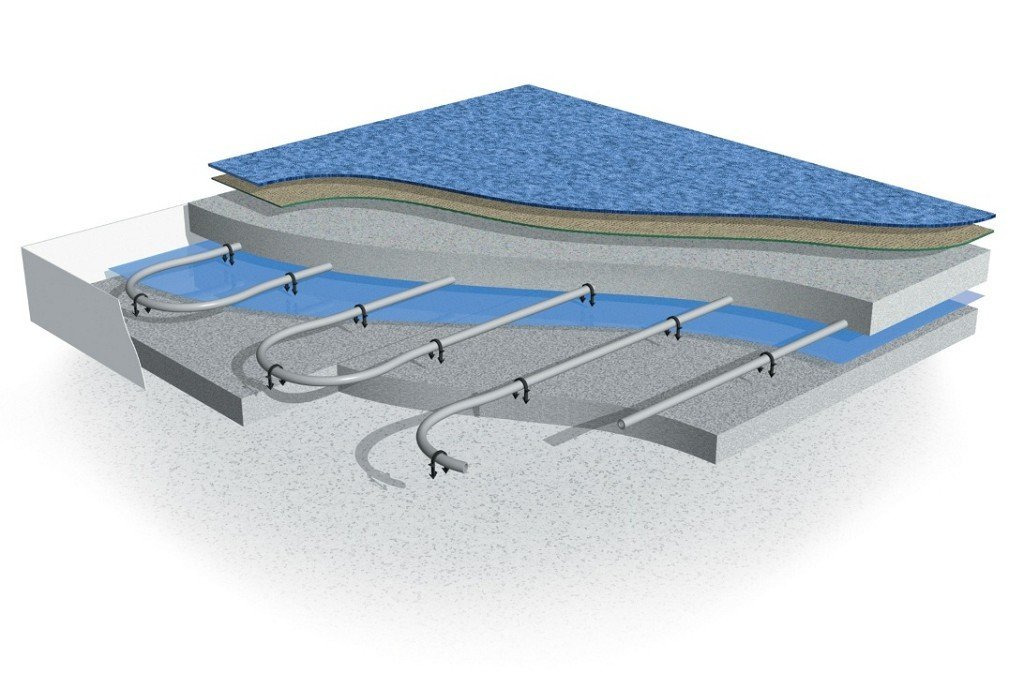

The thickness of the screed over the water warm floor is also determined and taking into account the diameter of the pipes. If the diameter does not exceed 25 mm, then there will be a layer of 50-70 mm. Experts believe that for normal operation of the system and good premises, the thickness of the screed over the warm floor can be 4 cm. If the screed is higher, then the thickness will complicate the adjustment of the feed of the heat, because the huge part of the energy will go to the warm-up of concrete.

What needs to be taken into account when setting a screed with a minimum thickness

After reading the sanitary standards and rules, you can understand that the smallest screed thickness can be equal to 20 mm. However, in this case it is necessary to take into account one feature. Depending on which material is used, the height of the layer can be different. If the screed is formed on the basis of a metal cement, then 2 cm will be enough. If you do not plan to use the reinforcing grid, then the minimum thickness cannot be less than 4 cm. This is due to the fact that the smaller layer height will not be able to provide wear resistance and sufficient coating strength.

If the minimum thickness of the heating floor screed is ensured, then you must comply with several conditions, among them:

- align the surface with a screed;

- the presence of roughing;

- lack of fittings and pipes.

If we are talking about the placement of technical purposes, then the maximum thin concrete layer cannot be used, because an increased load will be provided to the surface.

Additionally about the thickness of the screed of a water heating system

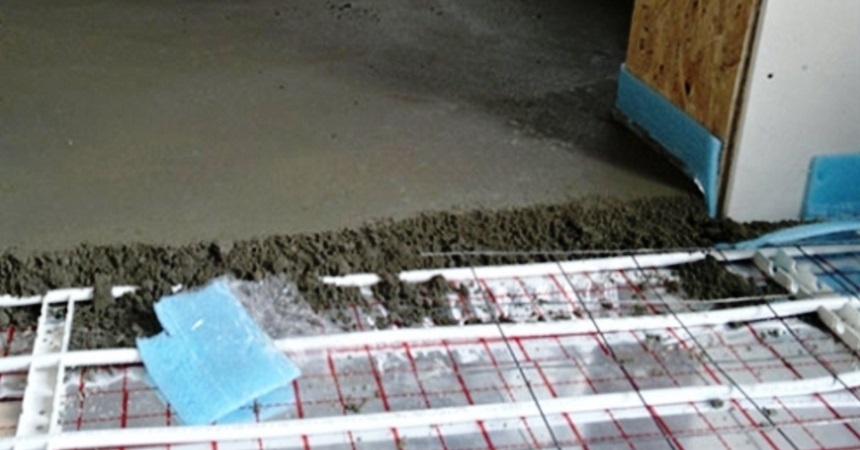

Water warm floor is a system of heating elements - pipes that are filled with water. They should be located all over the entire area of \u200b\u200bthe floor. Usually such a system is placed in a cement screed for protection against mechanical exposure. It is important to maximally calculate the thickness of the screed for water under floor. This will ensure the normal functioning of the system.

The thickness of the screed is the key to the mechanical strength and the correct performance of the system, as well as efficient heat transfer and efficiency. If you build a thick screed, it will have a large heat capacity, as a result, the temperature to regulate is much more complicated. The screed under such conditions is heated much longer, however, and heat gives a long period of time.

Laying the screed with a smaller thickness, you will get the floor heated in short timeHowever, such a design can overheat and be covered with cracks, the heat transfer will take strips that are limited to the step between the pipes under the floor. Choosing the thickness of the screed for a water heating floor, you must consider that this parameter determines the degree of pipeline protection and ensures a uniform distribution of heat over the surface.

The total thickness of the screed for residential premises should not be more than 100 mm. If we are talking about pavilions, auto center and warehouses, this parameter can be 200 mm and less. The thickness of the screed reaches 300 mm only in aviation hangars. The minimum thickness when laying a warm floor system is 65 mm. The thickness of the screed on a water warm field should be equal to the limit of from 20 to 50 mm. If the design is hanging, then the heat and sound insulation layer should be labeled between the pipeline and the base, then the thickness of the screed is 35 mm.

Pouring screed on the system Warm floor

Once you have determined which thickness of the heap screed should be, you should begin to work. The base is cleared, because the dirty overlap will not be able to provide the desired degree of adhesion. By clean and dry coating, you should walk the primer mixture in 2 layers. To calculate the volume of the screed, determine the thickness, multiplodent on the area of \u200b\u200bthe room. For residential and household rooms it is recommended to lay the screed range from 65 to 70 mm. The layer above the pipes will be 45 mm, while the thickness of the screed under the warm floor of water will be equal to about 20 mm. If you use mixtures for self-leveling floors, you can reduce the layer thickness to 45 and 25 mm, respectively. This is due to the fact that such mixtures have a higher density.

Experts are not recommended to save much on thickness, because in this case the floor can negatively respond to unforeseen loads. If in the room you plan to install large-sized items, you should envisage the upper layer reinforcement using metal grid. It is possible to use it point or all over the area. In order to strengthen the screed, you should use solid additives by type fibra or polypropylene chips. The first allows you to get a mixture called fibrobeton.

Choosing an impressive thickness of a warm floor screed, you will expect the layer's frozen to 1.5 months. Before starting to lay the finish coating, it is necessary to wait for complete dryness of the base. In this case, the bulk floor is more convenient, because it is distinguished by fast polymerization.

About the features of styling

If you decide to pour the screed for a water underfloor, the technology of work will differ only by the presence of damper seams. If we are talking about a room at 10 m 2, then the seams will be located on enclosing structures. A special depreciation band must be placed along the bottom of the wall. In the future, this will allow to compensate for the expansion of the material when exposed to temperature.

When the room is more spacious, additional seams will be required. Among the functions of the damper tape are not only compensation, but also thermal insulation from the walls, because the coating has a thermal foil foil. In order to achieve a positive result, it is not enough to choose the thickness of the screed on the water heat. It is also important to check the performance and hydraulic density of the system. It is necessary to ensure the presence of a heat transfer layer under the pipeline to eliminate heat loss. To the choice of materials for the screed should be approached as responsibly, it is relevant in relation to cement, which is incorrect and long storage Sleeps.

Conclusion

Before starting the floor alignment, the thickness of the heating floor screed must be correctly defined. This parameter depends not only on the wishes of the user, but also from constructive features buildings, overlap properties, floor power, facing materials and other factors.

Modern decorative flooring needs to be laid on a flat surface. It is allowed on the floor of minor defects, the depth and width of which make up several millimeters. It is important that the floor is without slope. Very rarely black floor has such parameters.

For alignment of the draft floor, a special solution is used, which after frozen forms a flat surface. Depending on the type of decorative floor and the black floor flaps, the aligning mixture is selected. For most apartments that have a standard height of 2.5 meters every centimeter on the account. Therefore, many are interested in what height the floor will rise after alignment.

In addition to the alignment of a rough base, the screed must withstand the loads rendered on the floor. This is not only the weight of the human body, but also the weight of the furniture, the fall in heavy items, the passability of the room.

Today there are quite a lot of blends in the market, which are used to align the floors. There are dry formulations that need to be breeded with water, there are already divorced and ready-made ready-made mixtures.

Many masters work exclusively with tested time by cement-sand solutions. The thickness of the solution depends directly on the nature of the black floor and the decorative coating, the need for hydro, sound and thermal insulation. If the insulation materials are pre-laid, the floor will rise at least 4 cm.

The thickness is determined in the basic nature of the draft floor. If there are defects of significant sizes or the draft floor is under a slope, the screed will be high enough. After all, modern floor coverings are quite demanding to the floor surface.

It is impossible to determine how long the floor is not. To do this, you need to use the construction level or the most ordinary bar, the length of which varies from 1 to 1.5 meters.

Having attached this block to the surface of the floor you need to see if the cracks between the bar and the floor are not formed, is there any dents or bugrov. If there were no such defects, there was not a lot of screed layer. Enough will put a solution 3 cm thick. If there are dents and bumps, then it must overlap the top point.

Even if the room is high enough, it does not impose too thick layer. From this, the quality of the black floor will not improve. In addition, it will be much more difficult to align the solution, and it will be long. It is worth considering and overrun building materials. Therefore, it is important to choose such a thickness of a screed that will not only block all flaws, but will not complicate mounting work. On the complete drying of the solution can be judged by light gray color.

Minimal thickness Cement-based screed is 3 cm. In this case, this height should be at each point. Due to the fact that the rough base is uneven, after filling the floor will not rise to 3, but about 4-5 cm. It is also necessary to consider that the cement-sandy solution gives shrinkage. This is due to evaporation of water. therefore desirableso that the thickness of the tie amounted to 5 cm.

If you put a thinner layer, then during operation, do not avoid the appearance of cracks. This, in turn, will reduce the service life of expensive decorative flooring. Experts are recommended to use such a type of screed in the event that the surface irregularities do not exceed 2 cm.

If, during the construction of the house, plates were used, the difference between which reaches 6 cm, then it is advisable for the alignment to use a solution from the sandbetone. For the preparation of the solution use coarse sand. The thickness of the leveling solution in this case is 8-10 cm.

There are cases when irregularities between the plates are up to 20 cm. In such cases, the ceramzite concrete is stacked. Align only one screed will be very expensive.

If the black base is concrete, and the height drops do not exceed 2 cm, then it is advisable to use self-leveling mixtures. By and large, specialists in this case use the term "layered". The thickness of the screed is determined by the mixture used. The manufacturer on the package indicates which the minimum thickness of the screed layer is allowed.

If the self-leveling mixture is placed on top of the waterproofing material, then the minimum thickness of the floor screed should be 4 cm. In this case, if it is necessary to hide communication, then it is necessary to put a 10-tisantimeter layer of self-leveling solution.

If the insulating material is laid under the screed, then the solution should not touch the walls. The emptiness formed, the width of which should vary in the range of 2-4 cm, after soaring the self-leveling mixture, it is necessary to be sealed with a damper ribbon or fill with an insulating filler.

The thickness of the screed depends on several factors, the main of which is the quality of the rough floor. The screed is done in order to align the surface. Accordingly, the more defects on the draft base, the greater the thickness of the screed. Also, the thickness of the solution depends on whether the insulating materials will be used and whether there is no need to hide communications.

Separately, you need to say about the warm floors, which have recently enjoy specially popular. These are engineering systems that serve to heal outdoor coverage. Water and electrical models are presented on the market.

Water warm floors are a certain way the lined pipe that is connected to the boiler. The pipe itself hides in the screed layer, which acts as a heat dissipation material. It is best to use self-leveling mixtures in this case.

You can prepare a solution based on cement, sand and water. But the prepared solution must have a certain consistency. Otherwise, cracks may appear, which will lead to the appearance of defects on the decorative flooring. Through the pipe is styling 3 cm thick. Therefore, the floor will rise at least 8-10 cm.

If we talk about the electrical engineering system, then the string layer is placed on top of it, the thickness of which varies from 3 to 5 cm. If the installation of infrared warm floors is performed, then you do not need to make the screed.

Another point to pay attention is to dry up. Cannot be laid decorative coatingwhile the screed does not gain the necessary strength. If, for example, we are talking about laying a parquet board on a cement-sandy solution, then it is possible, on average, after 28 days. The average thickness of the leveling solution is 4 cm.

According to the current standards, each centimeter of the solution dries within 7 days. If the solution thickness exceeds 4 cm, we need to add another 11-14 days for each subsequent centimeter. What concerns ceramic tile, It is possible to start the laying of the floor covering, on average, after 8 days.

Self-leveling mixtures dry much faster. If we are talking about a small layer, then it dries in 3-4 days. Polymer additives are influenced by the drying rate, which are present in self-leveling mixtures.

By placing the screed, you need to choose correctly not only the type of solution and method of fill, but also its thickness. As a rule, the solution is placed on top of a concrete surface, which does not have significant defects. Therefore, we can say that the optimal thickness of the solution is, on average, 4 cm. When installing the warm floors, the thickness of the screed layer increases.

Many masters are asked as the minimum thickness of the floor screed must be subject to certain conditions. It serves as the basis for exterior decoration, It works as a damper element, distributing the load, lines the surface. The answer depends on the set of factors.

The screed is considered one of the elements of building structures, the creation of which is mandatory if you want to get durable and durable flooring. To other solutions, several specific class solutions include improving thermal insulation indicators and even waterproofing.

The two main functional tasks of the screed include surface alignment and load distribution. In the first case, a particular value, which thickness of the floor screed will be made - depends on the existing surface configuration of the floor and room, geometry and height difference. Note that the minimum figure using modern materials It is only 3-5 mm.

The second task is to ensure the load distribution, directly depends on the strength of the layer. The norms, which thickness should be a floor screed - does not exist. There is an accurate requirement for technical indicators: the coating layer is obliged to withstand 15 MPa on compression and have a bias of no more than 0.2%.

The corresponding screed parameters can be made from:

- cement-sand mixture with a proportion of materials 1: 3, which is a classic option;

- modern cement-containing ready-made building mixtures;

- self-leveling compounds with polymers;

- mixes with the addition of clay, perlite.

To increase the strength of the layer, various means apply. If the minimum screed thickness is more than 80 mm, it is recommended to use a steel reinforcing grid. With smaller indicators - you can do a special plastic. If the thickness of the floor screed does not exceed 4 cm, it can be strengthened using polypropylene fibers.

How to estimate the acceptability of a particular type of solution

Very often in homes there are cases when the minimum layer of floor screed is sufficiently significant. This may be, for example, with a trudous form of the surface of the base, when the height difference is large and in the center of the room is formed a peculiar set. In this case, the parameter "Floor screed" is estimated, including, according to a permissible mass in accordance with the characteristics of the overlap.

To reduce weight, you can use various fillers of the mixture for the solution.

For instance:

- ceramzit crumb has the best combination of high volume and low mass;

- perlite is characterized by the property of the "fluffing" of the solution, increasing its volume with constant strength after frozen;

- slag and crushed stone are effective fillers, but the layer thickness when using them should not be less than 100 mm.

With the help of modern materials, you can cope with most problems associated with an excessive mass of the leveling coating. For example, the source floors can form steps, trough, the room can be a high height in the center. An excellent access is a multi-layer screed. The thickness of the layer is formed from the powder, the main storage area, the upper coating that provides smoothness. For each of the parts of the structure, it is necessary to clearly follow the condition for preserving the minimum thickness depending on the material.

Classic recipes

Let us dwell on the most applicable composition of the cement-sand mix. To prepare it, it is enough to stir the components and dilute them with water until the consistency of the thick sour cream. After that, the solution is stacked and aligned in beacons. Minimal thickness cement tie. This type depends on the set of factors:

- delta of the floor heights of the floor;

- room configurations;

- opportunities for convenient placement of lighthouses;

- bases for fill.

In the average case, when forming on a smooth durable basis, the minimum thickness of the floor screed from the cement-sand mixture should be 40 mm. These are the technical requirements set by standards.

- not less than 70 mm when laying without reinforcement on waterproofing wooden floors or overlaps on beams capable of deformation;

- not less than 50 mm when laying on concrete slabs to prevent the rapid departure of moisture from the layer and preserving its strength;

- not less than 100 mm when using perlite or clamzite for insulation.

These requirements can be used comprehensively. For example, to align the trudd-like base form followed the rule: the total height difference is divided into zones. The thickness of the floor screed in the apartment will be folded from the powder or layer with the addition of perlite, clamzite to reduce the mass and the upper - created with the use of cement-sandy solution with a thickness of at least 40 mm.

The minimum layer height can be slightly reduced - the German building norms allow a value of 35 mM for mixtures using grade 400 cement. These figures refer to a solo with a classic additive in the form of a lime milk for plasticization.

Application modern means Plasticization based on polymers will allow us to be unatherized to reduce the thickness of the screed - up to 30 mm. However, the cost of such consumables does not matter any comparison with classical. Their use looks rational only in the case when you have to save literally every millimeter of lifting.

Laying in a modern apartment

Modern housing can put a wide variety of tasks before the builders.

These include:

- floors with heating system "Warm floor";

- laying communications for the lower connection of radiators;

- flooring layer based on plywood;

- laying over electrical heating films;

- final coating on a semi-dry tie;

- flooring screed to overlapping the first floor in houses built on the ground.

In all cases, it is necessary to clearly follow the condition for creating the minimum thickness of the screeds so that the result achieved show an acceptable level of strength, durability, did not affect the characteristics of other structures and engineering networks. Although in each case, the indicators of the coating layer are selected individually, there are certain recommendations for certain solutions.

Laying with thermal floors and pipe communications

There are two values \u200b\u200bof thickness for a screed, inside of which there is a structure of liquid heating "Warm floor".

- The total thickness is 70-80 mm.

- The minimum thickness of the floor screed, located on top of the pipes - 30 mm.

When building a coating warm floors You can use standard cement-sand composition or ready-made building mixes similar formulations. The minimum thickness of 30 mm is compensated by the load distribution - the top layer is not isolated from the overall structure, therefore there is no problems with the strength of the surface.

In cases where it is necessary to form a layer of solution more than 100 mm for the tasks of the floor alignment or the achievement of high strength, an individual heat transfer analysis is performed. This is true for the location of pipes without binding to the upper level of the floor surface. If you make the laying so that the finishing layer is 30 mm - no additional calculations are required.

Film heaters

Floors equipped with film heaters are necessarily arranged by pre-used thermal insulation. It can be like foamed polymer materialsAnd natural - for example, cork flooring. The solution is widely applied using raised floor from boards on lags or plywood.

To cover such a floor, the requirement to its minimum thickness corresponds to the technical standards and should be 35 mm, when using reinforcement with polypropylene fibers - 30 mm. Create a screed of 30 mm may be needed for laying a tile with a minimum floor level lift. In this case, the use of polypropylene fibers or plastic mesh is necessary.

Modern materials

The so-called bulk self-leveling floors are the last word in building technologies. The composition for creating such a coating contains polymer components, which simultaneously protrude with plasticizers and form a solid, smooth surface.

The bulk floor can be used as a final screed, if it is necessary to make a very thin layer for the minimum lifting of the floor level. It is so written in almost all reference materials to the finished building mixtures of this class.

However, in fact, the minimum thickness of the screed of the floor of the self-leveling composition should be 2 cm, with a maximum of 30 mm. It is a slight more cement-sand layer with reinforcement, and the value of the solution is very large.

Laying a layer of supermala thickness

The level of 2-5 mm level for floor alignment is possible. Actually, it is difficult to call the screed. The covering layer is formed from adhesive compositions for tiles or special building mixtures.

General rules when creating screeds with minimal thickness

Screeds with minimal thickness meet the requirements of the industry and can withstand the normalized loads. The problem is that they have no durability stock. Therefore, the arrangement of the structure of the stack is carried out.

The list of measures includes:

- mandatory junction with the basis. To form a cement screed directly on the surface of the concrete slab - not recommended. The adhesion of the composition with the base will lead to transmission of mechanical loads and cracking. Therefore, the screed laying is carried out through the separator layer, which can be simple waterproofing from a polymer film;

- damping. Temperature expansion can lead to cracking of the minimum thickness screed. To avoid such trouble, a damper area is created around the perimeter of the room. The width of the lumen should be at least 20 mm. To form this element of the structure, a special construction damper tape is produced. It stacked around the perimeter of the room before creating waterproofing and styling.

The applicability of this or that material to create a screed is estimated individually. The cement-sandy mixture is leading by mass per unit volume. To reduce weight, perlite and clay crumb add to the solution. Lightweight ready-made building mixtures, which can also be used for floor insulation are available. When using such compositions, it is recommended to clearly follow the instructions of the manufacturer in the context of the indicator of the minimum thickness of the screed.

As a conclusion, it can be noted: creating a screed of minimum thickness, you should not ignore the instructions of the manufacturers of building materials and advice of specialists. Violation of the rules necessarily leads to a decrease in the service life of coverage, cracking and other troubles.

The video of the minimum thickness of the screed is only 1 cm:

The screed is a draft floor, the upper part of its base, which serves as the basis for the finish coating. Not only creates the most smooth surface for the future finite finishes, but also is the guarantor of the strength and durability of the entire floor in the apartment. The thickness of the screed has great importance: Too thin layer will not provide sufficient strength, too thick entails an unjustified overrun of materials.

The universal filling thickness indicator for the apartment does not exist, in each case, this parameter differs depending on the following conditions:

- the type and condition of the base, the material on which the screed is styled;

- materials used for the roughing device;

- operational characteristics of the room;

- selected finish coating.

Why do you need to calculate the minimum thickness of the screed?

The desire to reduce the layer of leveling material is correct not only from the point of view of savings and reducing the cost of repairs in the apartment. Here are some more reasons why you need to avoid while working with the draft principle "the thicker, the better."

- Too thick layer of coating reduces the distance from the floor to the ceiling.

- Excess the height of the layer over the warm floor reduces heat transfer and increases the energy consumption spent on heating.

- Neglecting existing standards may result in an emergency, for example, a balcony overlap may not withstand too thick and heavy layer of concrete.

- The thicker screed, the longer she.

- Too thick layer of material can affect the walls when expanding them, causing their deformation.

Tip: To avoid negative consequences From the thermal expansion of the material of the screed, before the pouring of the mixture it is necessary to salary the walls throughout the perimeter of the room by damper tape.

What is the thickness of the floor screed?

Consider individually all the factors affecting the thickness of the draft coating.

Base

The thickness of the screed depends on the degree of irregularity of the base. The greater the bias and differences of the height, the more thick layer of the material it will be necessary.

If it is required to perform an alignment of the base with insignificant flaws, the minimum thickness of the floor screed in accordance with the standards should be 2 centimeters. However, it should be borne in mind that in this case the reinforcing elements must be present in the fill, too thin cement-sand screed sooner or later cracks.

The compositions for leveling that do not contain any additional reinforcing additives should be laid in a layer of 4 cm. For the final leveling of the trouble-free base, it is also suitable. The minimum allowable thickness of the layer for such mixtures is small, depends on the specific composition and is indicated on the packaging by the manufacturer.

In the event that the apartment has significant floor height differences, which may arise due to insufficiently high-quality laying of the ceiling slabs, can not go about the minimum layer. In such a situation, the sandbetone containing coarse sand is often used. Sometimes surface irregularities is so great that when they align them exclusively with the help of the fill, its maximum thickness can reach 15 centimeters. Experienced builders know the secret to reduce the cost of mixtures: partial alignment can be made using or rubble, due to which it is possible to reduce the concrete fill layer.

The presence of an insulating layer

The thickness of the screed will also depend on whether it is done directly on the slabs of the overlap, or additional sound or waterproofing materials are used. If you put the solution directly through concrete slabs, then the minimum layer for cement sand or concrete mix will be 2 centimeters. If an insulating layer is used, preventing the adhesion of the screed with the base, its thickness should not be less than 4 centimeters. Such requirements are clearly spelled out in the Rules of SNiP.

Material used for screed

Semi-dry mixes

The minimum thickness of the cement screed, which still enjoys the greatest popularity, should be as follows:

- when using a mixture with the addition of different - at least 3 centimeters;

- when performing work with cement s sandy mixture without additives - from 4-5 centimeters;

- when used - 3 centimeters.

Important! Keep in mind that after a rough layer of concrete or cement, special mixtures for a finishing screed are usually additionally used. The exception is the floor under the tile, where the function of the final alignment performs tile glue.

The so-called bulk floor for which self-leveling mixtures is used, allows you to achieve the most thin layer - from 2 millimeters. This option is suitable for a fairly smooth surface, any material can be laid on the bulk floor: tile, laminate, or.

Important! For bulk gender, there are limitations - the maximum thickness should not exceed 2-3 centimeters, otherwise the coating is cracking over time.

The screed on the "dry" technology is made in cases of serious damage to the surface of the base, when the tree is selected as the finishing coating or to speed up the repair process in the apartment - there are no materials requiring long drying. Immediately after completing the creation of the draft floor, you can put a tile or any other selected coating. The thickness made on the KNAUF system can begin with a 3.5 centimeter, of which 2 centimeters come on sheet material (chipboard, plywood, GVLV). The rest is a layer of a falling material, which most often uses clay. If it is necessary to achieve good indicators of noise, hydro and thermal insulation, the layer of claying should be more than 4 centimeters, and therefore the thickness of the whole "cake" should be at least 6 centimeters.

Warm floor

O it is necessary to speak separately, because in this case it, in addition to alignment of the floor, carries the additional function of the heat distributor. At the same time, the main condition that concerns the thickness of the fill is the high-quality hide of the heating elements. If, with the arrangement of warm water floors, standard pipes with a diameter of 2.5 centimeters are used, the total thickness of the screed will begin with 5 centimeters. The minimum layer of material above the pipes is 3 centimeters. Specialists recommend in this case do not save and do not strive for the minimum indicator, since with a small thickness of the material above the pipes the surface of the floor will warm up unevenly. A too large layer exceeding 5 centimeters is also not appropriate, because most of the thermal energy will be spent on heating concrete. Optimal option There will be a layer thickness of 4 centimeters above the pipes. For electric heating floor, the minimum shared layer should not be less than 3 centimeters.

Purpose of the room

When choosing a black floor thickness, it is necessary to keep in mind the load on the floor covering in the room where the repair is carried out. In the apartment, the largest mechanical load falls on the floors in the corridor, bathroom, kitchen, as well as the hall. In these rooms should not be limited to the minimum possible layer and make the fill from 5 centimeters thick.

The screed is one of the most effective ways Policy alignment. In addition, it helps to create an additional layer of sound and thermal insulation. Due to the fact that this coating acts as the basis for subsequent laying decorative materialThere are many questions. For example, what minimal screed thickness can be done? The correct answer allows not only to competently produce all the work, but also calculate the amount of the required material.

Screed is an important link when carrying out repair and construction workThe exact definition of the minimum or optimal thickness can have a significant impact on the final result. Therefore, it is necessary to take into account the functions that turns the coating:

- In most cases, such a layer is created in apartment houses between overlaps. Due to the fact that the base is a concrete slab, which serves as a ceiling and floor, it is important to obtain reliable and functional flooring, hiding all flaws and irregularities. For such designs, the screed is performed in two stages: the draft surface is originally created, and then poured the pure layer.

- Uniform load distribution, which arises due to the impact of interior items. It is also important to take into account that the screed independently puts pressure on the basis, it limits its possible thickness.

- Creation of additional sound insulation and thermal insulation. Indeed, such a layer helps to achieve a good effect, but only when using additional materials.

Thus, there are certain conditions that affect the possible thickness of the screed.

Materials for tie.

Materials for screed are the compositions with various characteristics. The most popular variant for the draft finish is a mixture based on cement and sand, which is additionally added different components. A feature of such a solution is a long period of final drying, which is up to 9 weeks depending on the thickness of the layer.

Now the construction market has appeared more modern formulationsThey allow you to create a coating with a thickness of 3 mm. They are used to design the finish flooring and the final level alignment. Such materials are suitable for creating a layer to 6-9 cm, but it is extremely uneconomical: to the surface of 2 m2 for a layer of 1 cm with a thickness of 1 cm, not less than 50 kg of dry matter.

Minimal thickness

The minimum thickness of the floor screed is the parameter to which it is necessary to approach with full responsibility. Many masters rightly notice that it is possible to use a thin layer only in exceptional situations, to carry out such a fill of the solution for the purpose of saving is unacceptable. The result can be completely unpredictable. Incorrectly selected size will lead to the fact that the coating cracks and will not perform its functions. Therefore, there are certain recommendations that should be guided by the device. different species Shrews.

The use of cement-based mixtures

Minimal thickness cement-sand tie is 30 mm. Focusing on this indicator, it is necessary to take into account some nuances:

- Due to the fact that the coating often acts as a rough, you need to correctly define the highest and lower point of curvature of the surface. It is they will be the starting indicators to calculate the optimal thickness of the flooded layer.

- The cement-based solution gives a strong shrinkage, so it is advisable to create a 50 mm floor to obtain a thickness of 30 mm. That is, almost 2 cm will fall after evaporation of water.

- If you perform a thinner layer, then the surface when drying is dried by cracks. This situation may occur after some time, which will lead to deformation of the facing decorative material.

- To enhance the solution indicators with minimal thickness, the use of special additives, which improve the characteristics of the mixture and prevent its destruction. It is impossible to exclude from the process and reinforcement performed using a grid or fibrovolock.

With minimal thickness of the cement screed requires additional reinforcement

With minimal thickness of the cement screed requires additional reinforcement On a note! With strong drops for alignment, use the composition from the sandbetone. This material is smaller than the density, which reduces the load on the entire design. Its minimum thickness is 80 mm. When irregularities are more than 150-200 mm, it is advisable to pre-lay a ceramzite concrete.

Self-leveling compounds

Such mixtures are used with minimal sealing differences, they have proven themselves as a finishing or finishing option. In most cases, these compositions have a different basis that affects their characteristics. To accurately determine the smallest possible thickness, you must read the manufacturer's recommendations on the label.

Allocate the following parameters affecting the screed layer size:

- with minimal deviations, the coating is applied with a thickness not exceeding 3 mm;

- when it is required to arrange a layer of waterproofing, the minimum screed size should be at least 30 mm;

- if the flooring in the apartment has numerous defects, be sure to perform reinforcement using a fiberglass grid, the optimal screed thickness will be from 10 to 15 mm.

Of course, major deformations suggest the fill with a thicker layer. For such work, self-leveling mixtures are rarely used, but when they are used, the minimum size should be 50 mm.

Warm floor and pouring screed

Currently, warm floors are becoming increasingly popular, which serve to create a comfortable thermal regime in the room. There are two main varieties: products with heat carrier from water and electrical models.

The warm flooring device involves laying communications on the surface of the flooring. The masters note that for filling the screed during installation of this kind of structures, the mixture based on plaster is most effectively used. This material perfectly carries out heat, which provides the desired mode.

The thickness indicators of the layered layer:

On a note! Experts note that the minimum thickness of the screed layer when the warm floors must be 50 mm, this will provide the most comfortable indicators. Of course, it is better to focus on the recommendations of the mixtures manufacturers.

The effect of thickness on the drying process

The size of the screed is influenced by many parameters, among which the drying time is particularly highlighted. It is advisable to navigate the following indicators:

- Cement-sand solutions are considered fairly popular, but with a minimum layer size of 40 mm, they require about 3-4 weeks to final grazing. It must be borne in mind that the time indicator can differ significantly under various conditions.

- An increase in the thickness of one centimeter, which is due to significant lack of foundations, prolongs the breakdown time for 4-5 days.

- Self-leveling solutions need less misfortune. So, with a minimum indicator of 5 mm, it is necessary to wait about 5 days.

Thus, the minimum thickness when the floor screed device is quite an important parameterwhich significantly affects the end result. If we neglect the recommendations and reduce the size of the layer, the result may be completely unpredictable.