How to make a large reservoir for the reserve of water from cheap materials. Dacha Water Capacity DIY

Water tank in the country - Photo of ideas

We will not deny that the water storage tank is needed on any summer area. My husband and We are the first year of ownership dual district It was very shattered from the fact that the water accounted for all the time to wear in buckets from the water tower, separated from us at a distance of 500 meters. After some time, we had a suitable water capacity at the cottage - 250 liter blue plastic barrel.

Water storage capacity in the country

Yes, it has greatly simplified and improved my life at the cottage - the water tank is spent in three days, and we just once every three days give water in the water supply. So replenishment of fresh water occurs regularly.

This capacity is especially relevant if there is no water supply system. In this case, you can think about the rainwater accumulator, at least you will have technical water for watering. And you can collect precipitates just in such containers.

Ideas of water storage tanks in the country's dacha

The most common water tanks are 100 liters, 250 l, 500 l, 1000 l, 5000 liters. Very comfortable plastic container - Eurocub, reinforced metal carcasy. Calculate your own water consumption for each family member and purchase water tank slightly more, so to speak about the reserve.

Plastic water storage tanks in the country

Water tanks

If your consumption, like us, small, you can purchase water tanks per cottage at 100 l, 200 l, 1000 liters. If the volumes are missing, then several small containers can be combined into a single whole, while having received a significant increase in the overall cubic.

If your family and consumption are large, then take immediately water tank in 2000 l, 3000 l or 5000 liters. Of course, you need to understand that the containers of a large volume are very expensive.

Water storage capacity on the country's dacha

So, decide for yourself what volume do you need a container for water storage in the country?

Water containers forms

The most universal is rectangular water tanks. They can be easily placed in the corner, to connect together, put one on the other. The same applies to rectangular tanks - there are wide variety on the market.

Similar containers are often used for accumulation and storage. drinking wateror technical water for watering and soul.

Large capacity for collecting rainwater in the country

Also popular with round water tanks are also very popular - such a dacha tank can be installed on the pedestal and get the natural water pressure in your summer water supply. And dummy water tanks and rectangular tanks can also be lifted to the podium - the tower and get a small pressure in the water supply system.

Capacities for drinking water - what materials are suitable

When we chose from what material our container for water to the country, they studied reviews and opinions on the forums. As a result, they stopped on the plastic, simply putting a barrel in the shade, where the sun does not fall.

Large capacity for storing technical water in the country

Water stainless tank

Very expensive at a price capacity that meets all standards to food containers. Most often performed in the form of barrels, tanks. The stainless steel is used for drinking water, there is no sense to keep the technical water in such an expensive package.

Stainless steel water tank

Plastic water containers

Practical and inexpensive plastic water tanks. Installed easily, the container itself is quite light, without water, so one adult can install it at a permanent place. You can store both drinking and technical water, in shape there are absolutely different configurations, you can easily find under your needs.

Plastic water tanks

I believe that plastic containers under water are the most comfortable and practical for the country area.

Capacities metal for water

Most often, such containers are made from iron sheets subject to corrosion, therefore, such tanks require a protective coating processing. It just allows such products to be cheap. Cuts are often welded metal cubes for watering water.

Metal water storage container in the country

Appointment of water storage tanks

On the appointment of the capacity distinguish into several categories. Next, consider each option in more detail.

Water reserve capacity

Such tanks can be somewhat on the site, we, for example, have a separate watering tank, a drink container, a barrel for collecting water from a well. Drinking water, as already spoke, is stored in a barrel put in the shade, where the sun does not fall. For watering capacity, on the contrary, the sun.

Capacity for rainwater

Capacity for storing and collecting rainwater in the country

In areas with rain abundance, it is advisable to install tanks for collecting and storing rainwater. In the gutters with roofing rainwater is collected in tanks and is used in the future for watering or some technical purposes. We rarely have rain and this system does not make sense.

Cumulative water tank

Copy water tanks in the country - photo ideas

Such containers can be placed in front of the greenhouses, as is done by my aunt. As water is consumed, the water is added to such tanks. The material can be any, in the aunt, simple metal barrels from under the engine oil. Very convenient and fiscal - got a gift from the mechanics from the enterprise where it works.

Water storage capacity at 3 cubic meter

Installing water tank in the country

So, for water storage, you can use absolutely different products, buying tanks for collecting water and storage, think how to install it. If you are alone and help you, I recommend plastic.

Most often, there are either ground tanks or underground water tanks, as well as, as already spoke, raised on the rods - tower.

Idea of \u200b\u200bwater storage capacity from plastic barrels

What you need to buy and install the water capacity

In most cases, the container is self-sufficient, and it already has a crane, the lid for the bay of water. Instead of a crane, you can mount pipes to supply water along the water supply system immediately to the house or watering. You can connect the pump and compressor to get pressure in the system.

Capacity for the dacha - ideas

You can install a tank capacitance and get an independent flow of water under low pressure. Some containers for water storage are in heated attics, it allows you to use water at the cottage even during the offseason.

Large water storage capacity at the cottage and in a country house

In my selection, I tried to pick up interesting photos Ideas for your inspiration. See what options are and pick up for the future.

Eurocub - Capacity for water in the country

By purchasing, installing and filling the water tank, you provide yourself with your plants with liquid. You should not believe on the flow of water on a schedule, making a stock, you can not hurry to the cottage to the clock of watering, but come without traffic jams at a convenient time. Inspiration to you and creative success!

For normal growth, plants need water. No water - no harvest and vice versa. In different gardens societies, the issue of water supply is solved in different ways. Somewhere water is fed to the garden sites constantly, somewhere periodically, and somewhere there is no one at all. In the last two cases, it is relevant to have a water supply for watering on the garden.

This stock can be created in different ways.

Install a barrel on the stand so that the water flows from it by gravity.

Disadvantage: a small volume of water stock and the need to make a solid stand.

Of course, you can install a barrel of larger volume, for example 500 or more liters.

But even a thousand liters for garden plot It can be a little. Under it will also need a longer stand. If the site is large, then the container will be needed a decent volume, which is also decent. For example, 5000 liters capacity costs more than fifty thousand rubles.

It is possible to significantly save on the containers if you have a reservoir. For this, the pit of the desired volume is digging, which is lined with a polyethylene film.

The pit is filled with water, which is supplied to watering with the pump. Disadvantage: High laboriousness of the reservoir device, because You need to dig a pit. In addition, if in this place you do not need a reservoir, then the pit will have to be bought.

The irrigation system is simplified if using a pumping station.

In this case, the container can be placed at the soil level, and the water will be in the pipeline of your garden plot all the time under pressure.

The pumping station consists of a pump, a hydroaccumulator, pressure sensor, a dry stroke sensor and a pressure gauge.

The station is connected to the pipe container (hose) with the required use of the check valve. The second output of the station is connected to the tap system of the garden and at home. The station operates from electricity 220 V. When it is turned on, the pump pumps water into the plumbing system to a certain pressure, usually 3 bar.

Upon reaching this pressure, the sensor triggers and the pump is turned off. In the water supply system, water is under this pressure. Resetting the pressure in the container (reservoir) prevents the check valve.

When any crane opened in the system, water flows through it and water pressure drops. The pressure sensor is triggered and the pump is turned on. Water will flow into open cranes.

When the crane is closed, the pressure in the system rises, the sensor triggers and disables the pump. Water in the system is under pressure.

The hydroaccumulator contains a small supply of water (3-7 l), which can be used in the absence of electricity. Dry movement sensor will prevent the pump operation in the absence of water.

You can of course, instead of a pumping station, use only the pump. But at the same time will have to constantly include it when water is needed. When using a pumping station, water in the pipes will constantly and the pump will turn on automatically.

If the water fence goes from a reservoir or pool, then it is better to purchase a special connection kit.

It consists of their corrugated hose with a connector to connect to a pumping station, check valve and a filter grid. One end of the hose is connected to a pumping station, another dip in the reservoir and you can turn on the system.

Now about water tanks. Suppose you need to have a large stock of water (2-6 000 liters), you do not want to dig a pit or buy a plastic container. In this case, you can make a container for the water of large sizes on their own. You will leave for a few hours.

The essence of such a container - you make a box, stood it with a film and pour water into it.

Here is an example of a capacity of 7000 liters.

They crushed the soil area with a size of 3x3 meters. Three beams were used as the basis, they were put on bricks with waterproofing with a polyethylene film.

On the bars laid five boards with a thickness of 50 mm and fastened with self-drawers.

They laid two sheets of OSP - oriented chipboard.

The dimensions of each plate are 1.25x2.5 meters. Two plates were used on the base, therefore the capacity was 2.5x2.5 \u003d 6.25 m2. They were attached to the boards self-drawing with pressshaba.

On the perimeter, the base on each side was set by one sheet of OSP on the edge - these are the walls of the container.

At the corners and the grounds installed the boards. They enhanced the frame from above.

The main thing in such a design is to make a durable frame, because 7,000 liters of water weigh 7 tons.

It turned out a frame box with a smooth inner surface of the OSP.

From the inside you need to be covered with white needle-free geotextiles or syntheps.

It is necessary to prevent damage to the film with chips or screws of the screws.

They are fixed by a construction stapler to the boards of the top of the frame.

Inside the box, the stapler does not use, otherwise the brackets can damage the film!

We put the film, but do not fix and begin to pour water.

Under the weight of water, the film is stretched,

after that, you can attach it to the top of the frame of the construction stapler.

With insufficient frame strength, you can additionally strengthen its walls using inclined boards.

Then we install the pumping station and dip the hose into the water. We connect the pumping station to electricity, the water went!

If necessary, such a container is easy to disassemble and dispose of or collecting elsewhere.

The cost of the device of such a reservoir: the boards were available, six sheets of OSP cost 3500 p, the film cost 600 p. Thus, the capacity of 7 m3 was built in a few hours and 4100 rubles.

If necessary, the capacity of greater volume can be made in the same way. For this, the sheets of the OSP and the framework are added longer to the length, multiple sheet sizes.

For example, adding only four OSP leaf (two for the base and one by one to two sides), you will receive a capacity of 15.625 m3, that is, twice as many.

An important addition. Now among the gardeners is greatly popular drip irrigation. Gardeners put a barrel of 200 liters on the stand, plug in it with watering and enjoy the auto oppression of their beds. But not long, because two hundred liters of water digged very quickly.

Homemade frame capacity for large water in the complex with pumping station Provide you uninterrupted automatic drip watering of all plants throughout the summer.

Dmitry Ivantsov

novosibirsk Center for Natural Agriculture "Shine"

Installing water tank in the bath opens up a number of amenities and advantages over the owner. First, it is possible to prepare hot water in the furnace furnace process, which allows saving energy resources and consumes them as appropriate as possible. Secondly, the use of such an aggregate in most cases makes it possible to refuse to install electric water heaterThat also benefits the budget dedicated to the construction of a bath.

Several main requirements are presented to the tanks for water: they must be spacious, durable, warm up for the shortest possible time and retain heat for so long, as they dictate the needs of visitors to the steam. Among the options available to the ordinary user, the most listed criteria correspond to products made of stainless steel.

Scheme - An example of installing a remote water tank

The modern market offers a wide range of water tanks manufactured from cast iron, stainless steel and enameled material. As practice shows, it is the stainless steel among the owners of the bath, which is due to the competent and acceptable ratio of operational technical characteristics and cost indicators.

The stainless steel is characterized by excellent thermal conductivity indicators, it normally transfers temperature jumps and serves as one more than different ferrous metals.

A natural question arises: which of the existing stainless steel stamps is better suitable for the manufacture of the capacitance under consideration intended for operation in a bath basis? First, it is Brand 08x17 (430), secondly, 8-12x18n10 (304). The materials mentioned, among other things, are used for the production of dishes and are characterized by high resistance to high temperatures, are completely hygienic, not rust and not deformed during use. In addition, such materials are unpretentious and extremely simple in care.

Situating the foregoing, you can highlight 3 main advantages of water tanks made of stainless steel:

- products do not require the improvement of additional protection from high humidity air and normally transfer operation in conditions characteristic of a bathroom bath;

- the stainless steel is distinguished by high thermal conductivity, which makes it possible to receive hot water in as soon as possible;

- stainless steel tanks are not deformed due to sudden temperature drops or these deformations are insignificant.

Water tank design options for bath

Water tanks designed to use in a bath can have a different design. Basic options 3: Built-in tank, remote tank and unit installed on a pipe. You can familiarize yourself with the features of each design type in the following table.

Table. Stainless steel water tank designs

| Type of construction | Description |

|---|---|

| The installation of representatives of this category is carried out in the process of building a bath furnace, as a result of which the stove and tank become a single design. Water heating in a built-in stainless steel tank is carried out by fire, thanks to which the efficiency of directly water tank is held at a rather impressive level. A key disadvantage of such a design is the fact that a substantial part of the heat is leaving the water in the container, as a result of which the heat transfer directly falls noticeably. Useful remark! Much easier in manufacturing and use is a tank / mounted tank, installed on top of the heater. |

|

| More convenient and practical compared to the previous model version, especially if the tank is constructed and sets for permanent use. If desired, the finished tank for water from a stainless steel can be installed in the wash room of the bath, connecting it with a pipe system with a furnace heat exchanger. The optimal material manufacturing material is copper or brass. The only significant lack of a remote water tank is reduced to the likelihood of obtaining a burn in case of careless circulation - the position in particular is relevant if children will go to the bath. |

|

| A covered tank for water can be installed either directly above the bath furnace, or in the integrity space. In such structures, water heats up in the shortest possible time. At the same time, the indicators of the heat transfer of the furnace unit are not reduced. The undoubted advantage of installing the water tank in the attic room is the ability to "unload" the steam room, eliminating the capacity from its setting and ensuring more free space. |

The table does not include another possible option of installing the tank - on the side of the stove.

Oven with side tank - Photo

Oven with side tank - Photo

The way is deprived of attention for the simple reason that is the worst. Water in such a tank will very quickly throw. If the process of steaming is delayed, due to the constantly boiling water, the atmosphere in the room of the steam room will be simply unbearable. Yes, and with the maintenance of such a tank, solid inconvenience: in order to save space, the capacity is made high, but very narrow.

Having understood with the peculiarities of water tanks from a stainless steel and choosing the most acceptable design option, it remains only to determine the optimal capacity of the tank, after which you can move directly to the stage of its manufacture.

When choosing the required volume of water tank from a stainless steel, you must, first of all, focus on the planned number of visitors who will simultaneously go to the bath. For example, if the steam room is not capable of its physical dimensions to accommodate more than 2-3 people, you can safely put the tank at 50-80 liters, at the rate of 25-30 liters of water for each bunch.

Tanks are of different sizes - choose the appropriate

Operating the above recommendation, you can calculate the required volume of water tank, taking into account the attendance of the bathing bath. For more convenience, it is recommended to add an estimated value at least 10-20 l - the needs and ideas about comfortable washing every person different.

Production of a tank for water from a stainless steel with their own hands

Most factory models of water tanks are made of stainless steel with a thickness of 1 mm. For independent manufacture It is recommended to use thicker sheets - about 1.2-1.8 mm (the specific indicator is selected according to the capacity of the container). The cost of making a design in this case will be higher, but for many years you will not have to think about the need for repair, painting, covering various special compositions and other tank maintenance.

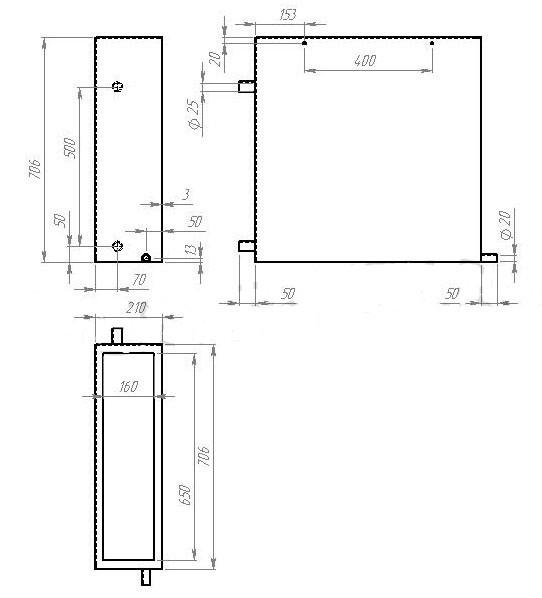

As an example, you can use the following drawing - it is the easiest for self-assembly And one of the most popular design options.

Dimensions can be proportionally changed in accordance with the required capacity of the container. The amount of volume is calculated according to the standard formula, i.e. Indicators of length, widths and heights of the product are sequentially multiplied. For example, the volume of the container represented as an example will be about 25 liters.

Helpful advice! An even simpler version of the water tank is a product made of seamless stainless pipe segment. By giving advantage of such a decision, you get a number of advantages. First, you do not have to spend time and strength on the cutting sheet metal, calculating points, stocks and other points, i.e. The likelihood of errors is reduced to a minimum. Secondly, the manufacture of water tank for water from the pipe requires the use of welding in minimal quantity.

The sale pipes made of stainless steel with a diameter of up to 1020 mm are available and even more, which allows without any problems to acquire a product for the manufacture of the capacity of the required volume. To determine the volume of the cylinder (namely, such a form will have cumulative Buck) Use the following formula.

Useful remark! If desired, no one will forbid you to make a tank made of profiled stainless pipe, and then the container will have a rectangular shape.

The further order of independent manufacture of water tank will be considered precisely on the example of using a pipe segment as a workpiece.

Pipe - Procurement

Important! If the installation of a bubbling water tank is planned, it is better to use a shorter to its manufacture, but a wide workpiece so that the chimney pipe can be skipped through the inner cavity of the tank. It will look like this as follows.

The procedure for manufacturing a water tank from the pipe is presented in the following table.

Table. Water tank manufacturing for bath

| Stage of work | Description |

|---|---|

| The formula was previously brought to calculate the volume of the cylinder. With it, we find the required height of the water tank. For example, we want to obtain a capacity of 30 liters and use a pipe with a diameter of 1020 mm for its manufacture. By simple arithmetic manipulations at the level of class 5, we convert the formula in the following form: H \u003d 30 / (3.14 * 0,512) \u003d 37 cm - precisely such a length should have a cut of a pipe to obtain a water tank of the specified volume. To cut off a piece of pipes, use the grinder. To work with stainless steel, discs with a thickness of 1 mm and a diameter of 11.5 or 12.5 cm. |

|

| To make the finished water tank beautiful view, It is necessary to handle the cutting zones accordingly. In the future, similar actions will be performed in reassuring holes for connecting nozzles with cranes. The most convenient tool that allows you to quickly and effectively cope with the decision of the mentioned tasks, is a manual borver. Such adaptations are equipped with a plurality of various abrasive nozzles, allowing to achieve maximum quality of the processing of a particular material. In the absence of a handmade borders of the seams will have to be put in order to underloaded means: a file, emery paper, etc., which is definitely a longer and time-consuming event. |

|

| At this stage, we will need a sheet of stainless steel. The lid and especially the bottom is recommended to do from a material having a more impressive thickness compared to the pipe walls selected for the manufacture of the case. Work is performed in several stages: - On the stainless steel sheet, the circle is drawn along the diameter of the holes that it will close. You can simply put the pipe on a metal sheet and draw the circle, circled product along the contour; - In accordance with the markup, 2 billets are cut. For cutting and subsequent grinding of edges, you can use the previously mentioned Bulgarian and manual bormer. If a hubing method of installing a water tank is assumed, at the same stage in the bottom and lid, you can prepare holes for the diameter of the chimney pipe (better by 1 mm more so that the chimney can pass through them, in the future the gap will be leveled by welding). Also at this stage you can prepare holes for the further connection of the tights with the cranes, if they are mounted in the bottom (relevant for remote structures installed aside from the furnace, in the case of the exhaust / built-in and hubbackers, pipes are more advantageous to cut into the wall of the body of the tank). In more detail, the nuances of drilling and welding of the stainless steel will be considered in the appropriate sections of the instruction. |

|

| The photo demonstrated a profiled tube, but the welding process for this case and working with a round blank remains the same. Products from the material under consideration can be connected in different ways: - with the help of soldering using selfless or high-temperature solders; - manual or automatic welding (in the case of stainless steel, work is carried out exclusively in the environment of protective gases). The most preferable is the second option, the simplest in mastering - manual arc welding. Argon is used as a protective gas. Welding is carried out using a non-melting electrode to work with a stainless steel. In the international classification, devices intended for such welding are marked with TIG abbreviation. Buying or renting a welding machine, do not forget to purchase / rent a balloon with argon and gearbox. The function of the latter is reduced to a decrease in the pressure of the protective gas at the output. Seams should be as neat as possible and homogeneous. After executing them, it is recommended to clean it. Recommendations for the appropriate tool have been brought earlier. Helpful advice! If desired, the tank cover can be not welded, but to attach with the help of bolts and ears or simply make it removable. The option is relevant for cases when the water will be added by the user manually, and not supplied by water supply. Capacity is ready. We proceed to the preparation of holes for the further cutting of the nozzles. |

|

| The designs under consideration are equipped with two tights with cranes. Cold water is traditionally supplied through the upper pipe into the container, and through the lower adjustable liquid goes to the consumer. The diameters of plumbing pipes correspond to the diameters of the water pipes used in the complex with them. Most often, pipes with a diameter of ½ or 1 inches are used. An ordinary electric drill is suitable for drilling a stainless steel. The main thing is that the work is performed on low revs - no more than 100 rpm. In a drill with an electronic regulator, the installation of the required mode is not a problem. If there is no such regulator, it is necessary to simply activate the start button with short presss - for a second, the tool will not have time to accelerate to operating power. The holes are best to make the R18 brand drill. An even more convenient option is a special stepped drill (shown in the image). Such a tool does not break the edges of the opening, so that it gets perfectly round shape. Along with this, for drilling holes with a diameter of more than 14 mm more convenient to use special nozzles - so-called. "Crowns". |

|

| The diameters of such crowns correspond to both inches and metric gradation of sanitary pipes. With the help of the appropriate crowns, you can also prepare holes in the bottom and lid of the tank if it is supposed to be covered. |

|

| Nozzles with cranes are available for overlapping water overlap. In the complex with a stainless steel tank, it is preferable to apply components made of the same material. In order not to spend too much time on the arrangement of the thread, the nozzles are simply welded to the holes prepared earlier. Recommendations for tools and welding regimens remain the same. After installing the water tank, in accordance with the selected scheme (will be considered below), plumbing pipes are connected to the nozzles (it was previously noted that it is best to use products from copper or brass) of a suitable diameter. The connection of the pipe with the pipe is performed by any suitable method, for example, using a threaded adapter. |

So, the water tank is ready, and even the pipes for the cutting pipes are already mounted. It remains only to connect the finished device for its subsequent use.

Connection of a tank for water from stainless steel

Important comments before starting work

Previously, it was noted that the following versions of the tank mounting are most common: inside the furnace, aside from it and in the chimney pipe. We offer the first option to be replaced by the method at which the installation of the tank is carried out above the chimney. This method is simpler in the implementation, while it can be resorted to its use, even if the furnace is already built - suddenly you thought that you would not need a similar heater, and after studying the material stated, all the advantages of using it and wanted to install in our bath .

Important! It will be possible to implement the mentioned replacement only in the case of collapsible chimney. The proposed method involves the combined installation of the tank - it will simultaneously be placed over the stones and around the chimney pipe, which will make the effectiveness of water heating as high as possible. Otherwise, you will have to either give preference to the built-in tank model (if the oven is only built), or install the unit at a distance from the stove.

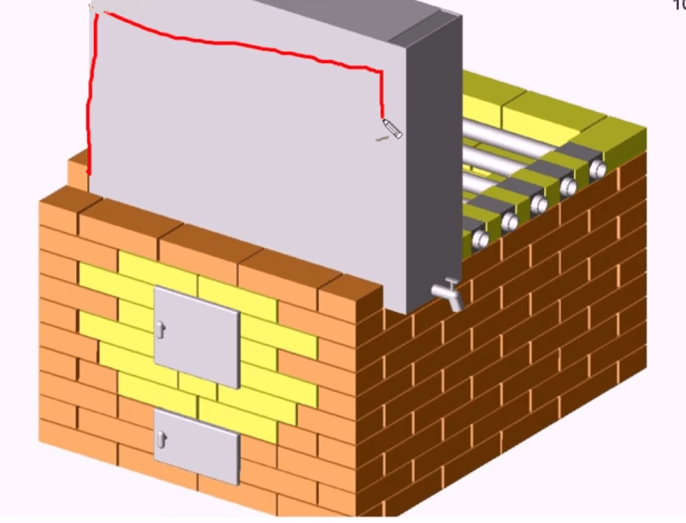

If the furnace is brick, the preparation of the place for the tank and its immediate installation is performed during the masonry process (the specific stage depends on the selected furnace design and the sizes of the furnace, most often it is 10 row). When laying a number, leave the opening for the placement of the tank. The size of the opening must be several millimeters to exceed the dimensions of the installed design to compensate for temperature extensions.

On the diagram - the opening of the tank

Note! In the intervals between the marked quarters of the brick, the pipes are laid, the presence of which will help increase the efficiency of heating - such are the structural features of a particular furnace unit, in the project you selected the pipes may be absent.

The furnace with the installed tank looks like this.

The sanitary faucet is embedded in the tank wall. It is assumed that the user will gain hot water right in the steam room. If desired, the design can be improved by embarrassing instead of the crane mentioned earlier nozzle by connecting to it water pipe And withdrawing it into the oil.

When the masonry is brought to the top of the tank, 2 metal strips are stacked on it, the presence of which will ensure safely overlapping the accumulative tank with bricks.

In the case of metal baths, the water tank is welded above the furnace (recommendations for welding were brought earlier). As a result, the heating of the tank is carried out by the forces of the flame, which ensures maximum fast cooking water. The design looks approximately so.

Important! If preference is given to the built-in tank design, it is necessary to use a metal with a thickness of more than 1 mm and, at the same time, to ensure that the quality of the welds is as high as possible. Otherwise, the tank either quickly prohibit or gives to flow through poor-quality seams.

Helpful advice! In case of brick stove, You can go easier by putting a water tank on the furnace housing over the furnace. The design looks like this.

Installing a tank for water over Kamenka

This method, as noted, involves combining the options for installing the tank over the heater and on the chimney pipe. The distance between the Kamenka and the bottom of the tank is usually maintained in the range of 20-35 cm with the ability to change in both directions: the smaller this indicator, the faster the water is heated, but the tank will last less, and vice versa.

Give detail step-by-step instructions It makes no sense - you already own all the necessary knowledge. Previously, it was told how to prepare holes in the bottom and a tank cap for passing through them the chimney pipe. Do it.

Next, you need to hold an element of the smoke system through the internal cavity of the tank and connect the pipe with the tank in the entrance and exit places (in the bottom and lid) using welding. How to do you also know.

Water tanks made of stainless steel have a relatively small weight (for example, the cast iron is much more severe and the tank will require fixation to the ceiling with a chain or another suitable way) and the additional attachment do not require. Further installation of the chimney is performed according to the standard diagram, depending on the type of construction selected.

Ideally, the finished system will have the following form.

On the image presented as an example, nozzles and cranes are not visible. The next design is not so beautiful externally, but the connection of the output of water here is clearly demonstrated but.

As for the feed cold waterIt can be organized in several ways, depending on the specifics of the specific situation:

- tank filling is carried out manually;

- water is supplied from well / well;

- water supply is carried out from the centralized water supply system.

We will not consider in detail each of the listed options, because These are themes for individual volumetric instructions.

Installation of remote water tank

The arrangement of such a system is also not distinguished by excessive complexity. The only scheme is complemented by a new device - heat exchanger. It can be embedded or external. For self-making, it is better to choose the second option - it is more convenient and easy to implement.

System of the system with remote water tank is presented in the following image.

Here we see that the external heat exchanger is installed on the chimney pipe. The water in the heat exchanger is heated due to the heat of the flue gases transmitted through the walls of the pipe. If an open heating is located under the heat exchanger, additionally heating will be carried out by heat with hot stones.

Heating in the heat exchanger, water goes to the outer tank, from there, cooling, back to the heat exchanger. Water circulation will be provided by the created slopes and pressure differences in the container with hot and cooled liquid.

Remote Tank S. hot water at 60 L.

The heat exchanger you can do yourself. In fact, it is the same tank for water, the instructions for the manufacture of which you have already studied, only smaller volume (usually up to 5 liters). The installation of the heat exchanger is done as well as the tank in the previous instruction (on the chimney of the pipe).

Register - heat exchanger for bath stoves

How to make the necessary holes, install nozzles, cranes and pipes you already know. Where to do - look in the scheme. It remains only to prepare all the required elements and assemble them into a single system, withsting the necessary distances and biases in accordance with the above scheme.

In this example, the remote tank for water is installed in the waters and is equipped with a standard plumbing crane for water drain. Pipes, like the said tap, are embedded in the bottom of the tank. Holes for laying pipes through the partition can be performed using a suitable tool, for example, a perforator.

In accordance with the current provisions of the current standards, the cold and hot water pipelines, in the case of their laying through the partition, must be laid through the sleeve. The latter diameter is selected so that 0.5-1 cm exceed the outer diameter of the pipe mounted. For the sealing of the gap between the sleeve and the pipe, a non-controlled soft material is used so that the ability to move the pipe along the longitudinal axis in the case of temperature extensions. Schematically, this is shown in the following image.

The gaps in the partition can be masked in any suitable way, for example, by filling out the mentioned soft non-aggravated material and closing the element outdoor decoration (lining, etc.).

It remains only to figure out how to fix the water tank on the wall. The easiest option is to install on metal corners, the power of which would be enough to withstand the weight of the tank with water.

The mount is carried out as follows. Applying corners to the wall, you put on the surface of the tag, drill the holes on the labels and mount the dowel in them. Next, screw the corners to the wall using a bolt of 8-10 cm long and a diameter of 1-1.2 cm.

On corners can install your water tank. The method is extremely simple in the implementation, but not the most reliable (made a mistake when choosing a corner - they rushed - the tank fell), and it is suitable only for rectangular structures of a small volume. The fastening method used during the installation of household water heaters is more reliable. To implement it, you will have to work again with welding apparatus. You already own all the necessary knowledge, so no additional explanation is required. Procedure Next:

- the metal strip is cut (the same stainless steel is suitable) with a thickness of 1.5-2 mm, 5-10 cm wide and long to perform for the lateral walls of the heater for several centimeters on each side;

- the holes in the diameter of the fastening bolts are drilled in the strip (you will understand when looking at the image presented below);

- the finished mounting plate is welded to the rear wall of the tank.

Further actions are similar to the previous instruction, with the only difference that the water tank is not installed on the corner, and is attached to the wall through them by means of a welded strip. It looks like this.

Tank is installed. It can be tested and, if everything is fine (there are no leaks, excessive heating and other adverse events) to take construction into continuous operation.

If desired, the system can be improved almost indefinitely, making a variety of automatic, measuring tools, etc. It is not excluded and the possibility of installing an additional layout in order to connect the tank to the shower cabin in the wave - this will allow you to wash with maximum comfort. An example of implementation of this idea is presented in the following image.

Helpful advice! The tank is installed in such a way that it is minimally distinguished from both a bath in the furnace and from the place of hot water.

Just mastering the art of welding a stainless steel, if you wish, you can make a tank not from the pipe, and from the sheet material is more responsible compared to the work considered. An example of its execution is highlighted in detail in the applied video.

Good job!

Video - How to make a tank for water from a stainless steel for a bath

Each dachnik knows that it is necessary for watering a warm, heated water in the sun. For this, daccias use all sorts of capacity: barrels, etc. I'm on my land plot I use concrete tanks. Make them die every gift.

To do this, first of all you need to prepare mobile formwork.

The dimensions of the formwork are calculated individually, depending on the volume of the future tank. My formwork (see the drawing) is designed for 600 liters with a height of 1 m. You manufacture all the details of the formwork, it needs to be assembled and to dig a pit for the foundation for the resulting size. Increase the length and width of the pits by 5 cm! At the bottom of the pits, pour sand (5 cm). The thickness of the foundation is 30 cm.

When the foundation concrete will cause (in the summer of 7 days), you can start collecting the formwork and cast the walls. The bottom of the container is cast simultaneously with the walls! To do this, you need to cut down a 10 cm width on the outdoor shields from below, turn them off after the formwork is removed. The thickness of the walls of the tank must eventually turn out to be 10 cm.

For accuracy between shields temporarily settling on the pouring pieces of the rails 20x20x100 and tighten the studs. During the fill of concrete, it is necessary to lay fittings. You can add a grid or bend the rings from the wire with a diameter of 6-8 mm. The distance between the reinforcement is 15 cm. Concrete needs to be very strong, cement does not save. Composition composition:

1.5 sand buckets,

1 Bucket cement brand 400,

Crushed stone (1 bucket with a diameter of 10-20 mm).

Mix thoroughly. Concrete must be liquid to easily pour into formwork. During the pouring, the formwork needs to be tagged with a hammer, then concrete will take place without shells. After 10-12 hours, when the concrete grabbies, it is necessary to remove ^ tie studs, because In the morning it will be very difficult to remove them. In the morning we remove the inner shields, and in a day - external. After that, we absorb the formwork again on the cast wall and fill again.

When pouring the first row and the bottom, do not forget to insert a piece of pipe with a carving, then to wind the valve later on the thread, as it is necessary to merge water for the winter.

When the container will be cast, it is necessary to choke inside. To do this, we prepare a solution: 1 sand bucket, 1 cement bucket No. 400. It is desirable to add liquid glass to the solution (1 cup) or waterproofing (500 g per 10 kg of cement). On the second day after plaster, the container can already be filled with water.

For the winter, water is sure to drain, and cover the capacitance with a lid, rubberoid or roofing gland, consolidating so as to the wind. The upper part of the tank should have a slope so that water flows from the lid. With proper operation, the container will last for a very long time.

On a note:

People who love comfort and convenience will definitely build a pool at the cottage. It's nicely in the sunny weather to be in the water or swim. But the maintenance of the pool is very laborious work, so it is better to trust the professionals, which will qualitatively spend all cleaning work in the pool, correct breakdowns. And you will enjoy the fresh air of nature and clean water Your pool.

Water is a source of life, and without water a person cannot exist. In addition to drinking, water is used in everyday life, and for a full-fledged comfortable life, the owner must be taken care of the source in its plot. The water supply is far from each local village, but there is a lot of options, how to install a storage capacity near your home.

What kind of varieties are

Depending on the purpose of using water, the tanks are several species:

- metal;

- plastic;

- reinforced concrete xenons;

- homemade tanks;

Metal

If water is used for drinking and cooking, the reservoir is made from high-quality stainless steel that meets all standards. For air exchange in such containers, holes covered with grids and precipitation protected from atmospheric precipitation are provided. Two pipes are connected to the tank: applying and discharged water on which water taps are installed. Such tanks 2 times a year need to be cleaned and disinfect, for which a special hatch is provided, through which a person penetrates inside. The main drawback of such a tank is a high price and the high probability that the metal capacity can be stealing if you leave it for a while without supervision.

There are also rainwater tanks. They are made of lowest quality metal than drinking water tanks. But it is not always bad. As statistics show, in summer, a person uses 100 liters of liquid every day, of which most of which goes to watering the garden and other household needs. In order not to spend big money on use on the domestic needs of drinking or tap water, there are special tanks for the accumulation of rainwater. It consists of a working part where liquid flows in the form of precipitation, and the room for equipment where filters are located.

There is such a reservoir under the roof of the house where the drain roofing system collects water and on special gutters directs it to the tank. But this is a fairly expensive system, so the usual gathering to put it in itself is inappropriate. Rainwater can be used for washing up soft water, watering plants, etc. At the same time, if the house is large enough, and it is located in a zone where summer is often rainy, significant savings will be noticeable.

The easiest option is to install a conventional metal barrel at least 5 cubic meters. l. and wall thickness 5 mm. The main advantage is the ability to leave water for the winter. Then in the spring it will not be necessary to worry where to take water for household needs. Among the minuses of the metal barrel can be noted:

- the need to paint the surface so that it is not covered with rust;

- hard to transport;

- if it is made of valuable metal (aluminum, galvanized), barrel can steal.

Plastic

The most popular are plastic water tanks for cottages. This is due to the main advantage of plastic - low weight and possibility of transportation. In addition, the advantages of plastic tanks can be attributed to:

On the market you can find the plastic capacity of any shape and size. Thanks to the hygienicness of the material, the suppliers of drinking water to order are precisely plastic containers, such as the Eurocup of any sizes.

Table: Types of water storage tanks

| Capacity | Volume, L. | Height, see | Diameter, see | Wall thickness, mm | Weight, kg | Price, Ros. rub. | ||||||

| Vertical | 100 | 70 | 48 | 3 | 4 | 1230 | ||||||

| 300 | 86 | 71 | 5 | 10 | 2725 | |||||||

| 500 | 107,5 | 83 | 5 | 16 | 4920 | |||||||

| 1000 | 140 | 103 | 5 | 28 | 8580 | |||||||

| 5000 | 210 | 185 | 7 | 110 | 33110 | |||||||

| Horizontal | 150 | 59 | 53 | 4 | 6 | 1780 | ||||||

| 500 | 83 | 83 | 5 | 18 | 5420 | |||||||

| 1000 | 103 | 103 | 6 | 30 | 8950 | |||||||

| 1500 | 123 | 123 | 6 | 40 | 12310 | |||||||

| 2000 | 125 | 120 | 7 | 60 | 16820 | |||||||

| Rectangular | l. | width, see | height, see | length, see | mM. | kg | ||||||

| 100 | 40 | 48 | 80 | 4 | 5 | 1560 | ||||||

| 200 | 48 | 57 | 100 | 4 | 8 | 2430 | ||||||

| 300 | 58,5 | 60 | 123 | 5 | 12 | 3380 | ||||||

| Flat | l. | width, see | height, see | length, see | mM. | kg | ||||||

| 1000 | 67 | 153 | 140 | 6 | 34 | 9540 | ||||||

| 2100 | 78 | 235 | 152 | 7 | 72 | 20110 | ||||||

| For transportation | ||||||||||||

| l. | width, see | height, see | length, see | mM. | kg | |||||||

| 1000 | 103 | 103 | 150 | 8 | 36 | specify price | ||||||

| 2000 | 120 | 125 | 213 | 9 | 70 | specify price | ||||||

| 5000 | 184 | 250 | 185 | 10 | 205 | specify price | ||||||

Reinforced concrete

This is a special type of accumulative water tanks. It is a reinforced concrete monolithic structure in which you can store a large number of water. Only professionals should be engaged in installation and installation of xenon, because poor-quality compound of plastic waterproofer sheets can disrupt the tank tank, and water in it will quickly deteriate. However, the cost of such a structure is very large, so it makes no sense to establish such a monumental design if it has no farm in 300 cattle heads and a huge plot of 20 hectares.

This is a special type of accumulative water tanks. It is a reinforced concrete monolithic structure in which you can store a large number of water. Only professionals should be engaged in installation and installation of xenon, because poor-quality compound of plastic waterproofer sheets can disrupt the tank tank, and water in it will quickly deteriate. However, the cost of such a structure is very large, so it makes no sense to establish such a monumental design if it has no farm in 300 cattle heads and a huge plot of 20 hectares.

In the event that there is no money for the drive for water for the factory-made water, or other circumstances are hampered by this, you can take advantage of undergraduate tools and build a drive from what is at hand.

How to make a cumulative water capacity with your own hands

The best for such purposes will be tractor tires, namely, tires from the diesel tractor T-150. Or you can at any enterprise or in a fleet to buy a used tire from a cargo machine. It is necessary to immediately say that water from such a tank cannot be used for drinking or cooking. Only for household needs! And such a tank becomes simultaneously with a rainwater storage device that does not contain chlorine. Unlike plastic, the tire capacity cannot be pierced or scratched. The tire does not rot and does not let water.

Stages of tank manufacturing tank:

- Align the surface on which the tire will lie.

- We put the bus and knife to cut its upper part.

- We make a solution of 30 kg of sand and 10 kg of cement.

- The resulting solution fill the bottom of the tire and align the solution with a spatula. This must be done to impart stability.

- It is necessary to wait a week to dry the solution. Everything, the tank is ready!

Capacity will be very by the way in the country. Water can also be used for irrigation, and for other household needs.