Features and an example of calculating the electric heating cable for water pipes. Self-regulating heating cable for water supply - pipe protection from freezing

In some situations it is necessary to pave a warming cable for water supply inside the pipe. In those regions where in the winter period the temperature reaches very low marks, people justify the question: ", because ordinary insulation in such regions does not always effectively protect against freezing."

To avoid this, the highway is heated from the inside. These actions allow you to maintain the desired temperature of the pipeline with a significant decrease in temperature.

What is heating cable

Such heated is very common in many regions of Russia. Heating self-regulatory cable for water supply, installed inside the pipe, is essentially an electric cable, where the resistance regulates the temperature rate.

A self-regulating and resistive electrocabolic uses one of the possibilities of the conductor from the metal, which, passing through the electrotocks, is heated.

Accordingly, the higher the resistance level, the greater the device heats up. It is clear that, because it is in the water.

Include self-regulating heating wire at a temperature of + 5 degrees inside the water pipeline. With a decrease in temperature ambient, resistance to self-regulating and resistive wire increases, therefore, in the plumbing support the desired temperature water.

You can buy this wire for various lengths. It may be types from two to twenty meters. They allow you to warm the wire part of the water supply system, or the entire system, if it is located in the freezing zone.

Watch the video

At first glance, such a wire seems to be a very simple device, which can be installed with your own hands, and make an effective warming up water supply. But, in order to correctly choose and mount the heating cable inside the pipe, it is necessary to carefully examine all the information that will be set down below.

Device of heating electrical conductors

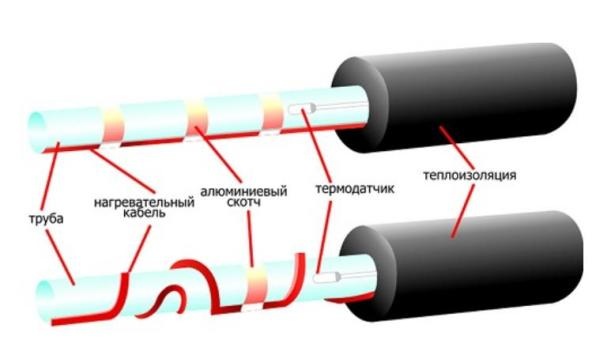

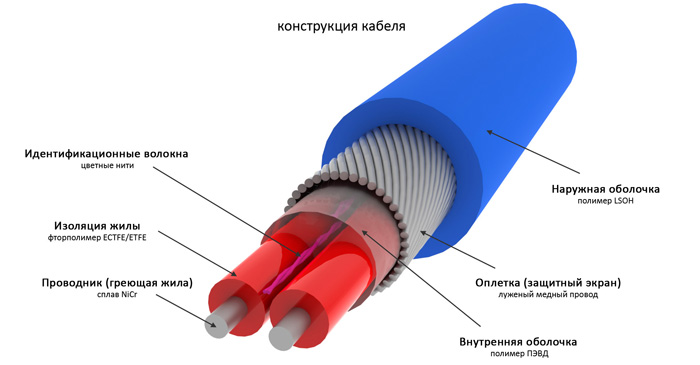

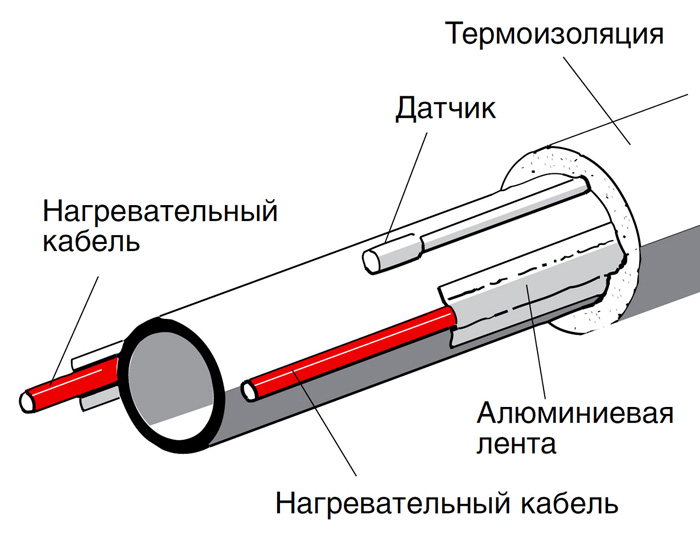

The heating cable for broaching inside the network is produced in the form of a ribbon electric heater. In the context of the heating device, you can see the following components:

- Metal conductor for heating.

- The veins of the heating electrocabel coated with heat resistant PVC (polyvinyl chloride) isolation.

- The inner insulation layer covers protection from fluoroplastic.

- All conductors are enclosed in the screen in the form of a grid of copper.

- The latter outer insulation layer on the heating device is also made of heat-resistant PVC coating.

The outer layer of insulation on the heating cable has the following characteristics. It is stable not only to the effect of moisture and high temperature, absolutely not afraid of the effects of an aggressive chemical environment.

Also, the cable for broaching inside the water pipeline is made from materials, the composition of which is allowed in food production. Consequently, it can be put in the system with drinking water.

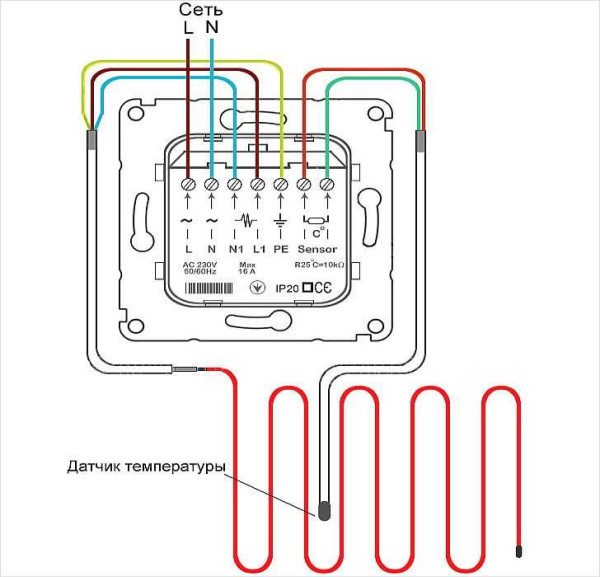

In addition, the warm-up cable is equipped with a temperature regulator. This allows you to control the temperature inside the water pipeline. If the temperature indicators exceed the specified parameters, the system turns off the machine. These features of the device allow you to prevent overheating and economically consume electricity.

The warm-up cable for installation inside the system is distinguished by the following advantages:

- Reliable work of warm appointment.

- High security.

- The ability to use the warm-up wire both inside and on the outer part of the system.

- Simple installation and easy operation.

- The ability to save electricity through a vehicle regulator.

Perhaps the only disadvantage of these warm-up systems becomes their dependence on electricity. For these reasons, at the main directions of the pipeline, it is recommended to install additional power sources.

Types of heating wires

Heating highways inside depending on the method of heat generation is performed by devices of the following types:

- Resistive.

- These wires for warming are: zonal and linear. Linear produce heat when passing through the electrotock conductors. Such warming devices consist of one or more metal lived. They can have the shape of a spiral on the resistive mechanism for warming up.

- The self-waving warming cable for laying inside the water supply on the principle of operation resembles the previous type of devices.

This self-making wire can be installed not only within the network, but on its surface part. This electrocabel can have when raising temperature norm Alone to reduce the level of thermal powder.

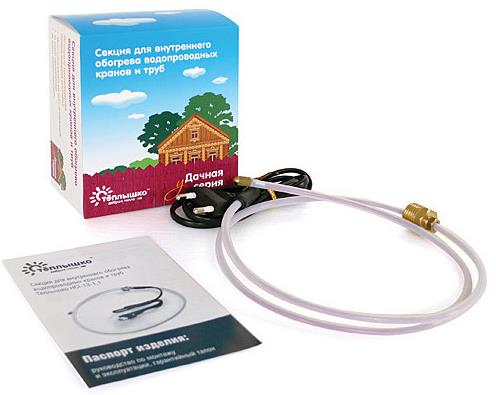

At the specified reasons, it is great for installation on small sites Highway. It is not necessary to put the thermostat. Self-greasing cable type systems are not only with a thermostat, but also by various elements for installation and special seals - adapters for broaching inside the water supply.

The self-waving heating cable of this species was widely distributed in all systems: HDPE, metal, metal-plastic, etc.

How to choose an electrical cabbage to warm up the water supply

The inner cable for heating the use of the type of use is divided according to power indicators. For use in the household highway, it is better to put low-power kit for heating. For example, for country house And the cottage use mechanisms for heating with a power of 50 watts per meter pipe.

The magnitude of the heat loss depends on the volume of the pipe and the quality of the heat insulating layer. For example metal pipe At 50 mM insulation by 20 mm effectively heats up with a heating device with a power of 21 W / m.

At an important main direction for heating, a cable system with high power is put. Before mounting such a cable system, you should know that the power in the heating wire is selected in accordance with the diameter and length of the main line. But, the consumption of electricity for heating in this case will be tangible.

Watch the video

The highest popularity of specialists use the goods "Raychem" (Germany). This trading line is represented by a variety of models that apply not only at industrial enterprises, but also in domestic pipelines.

Any cable kit that offers this manufacturer is characterized by a higher price than similar options from other manufacturers. But this is fully compensated by the functions performed by them.

Also, professional masters in the line of high quality goods ranks the Russian company "Yulmart", which quickly won popularity from consumers.

Special attention deserves a set for heating the "Underlux" pipes of the production of Germany. This kit, which is intended for laying within the network, and most often apply to everyday life.

This system has received the conclusion of experts on hygienic security, which is evidence that it is allowed to put into a network entry drinking water. The heating temperature of the "Underlux" set throughout the length is under a permanent self-control system.

Making the installation of Underlux products is not difficult. This is done with the help of fittings made by casting. The main advantage of this self-regulating device is the ability to independently change the parameters of the work, depending on the ambient temperature.

This advantage provides long-lasting and reliable operation. Kits that provide this manufacturer are distinguished by high efficiency and the ability to save electricity. They can be put in a plumbing and drain system, in the water pipeline system, etc.

Overview of various manufacturers can be continued for a long time. The main thing is that you need to do when choosing, it carefully examine the pros and cons of the proposed options. Also, an instruction from manufacturers is attached to each model. It also needs to be carefully examined before work.

Watch the video

You can buy a good and high-quality product from many manufacturers, but at the same time it is better to contact the proven company. If difficulties arise with the determination of the number of purchased wires, consultants will help this calculation.

In addition, they will help you choose a suitable product at a reasonable price. By the way, it is necessary to add that the best place To buy heating electric pipes for pipes, the construction hypermarket "Lerua Merlen" is considered. There is always a large selection of products that are distinguished by high quality and acceptable cost.

Mounting work

Installation of heating wire in the pipe must be performed by experts. They will not only determine how many meters need to be bought, but also will install the heating device in compliance with all safety rules.

As well as for highways from other materials, it constantly functions in water and can be a source of health hazard.

Therefore, if a warm water pipe creates a professional master, then it takes into account all the subtleties of the installation. And in small areas of the water supply, this installation can be performed independently.

Rules that must be observed when installing heating electric pipes.

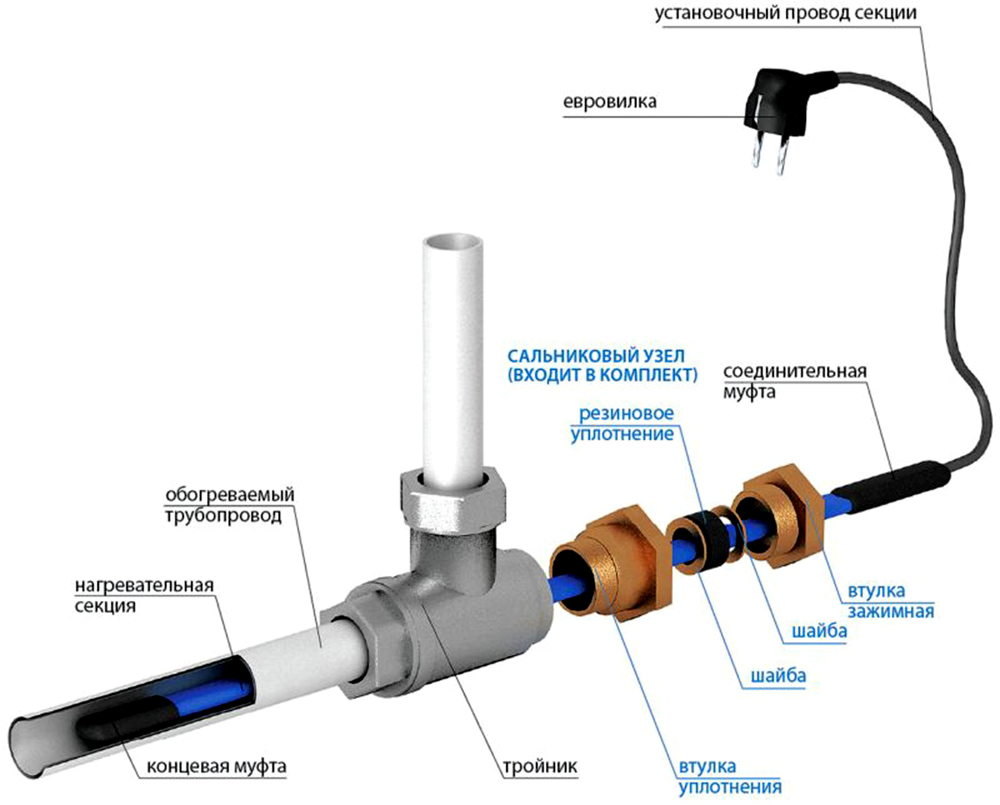

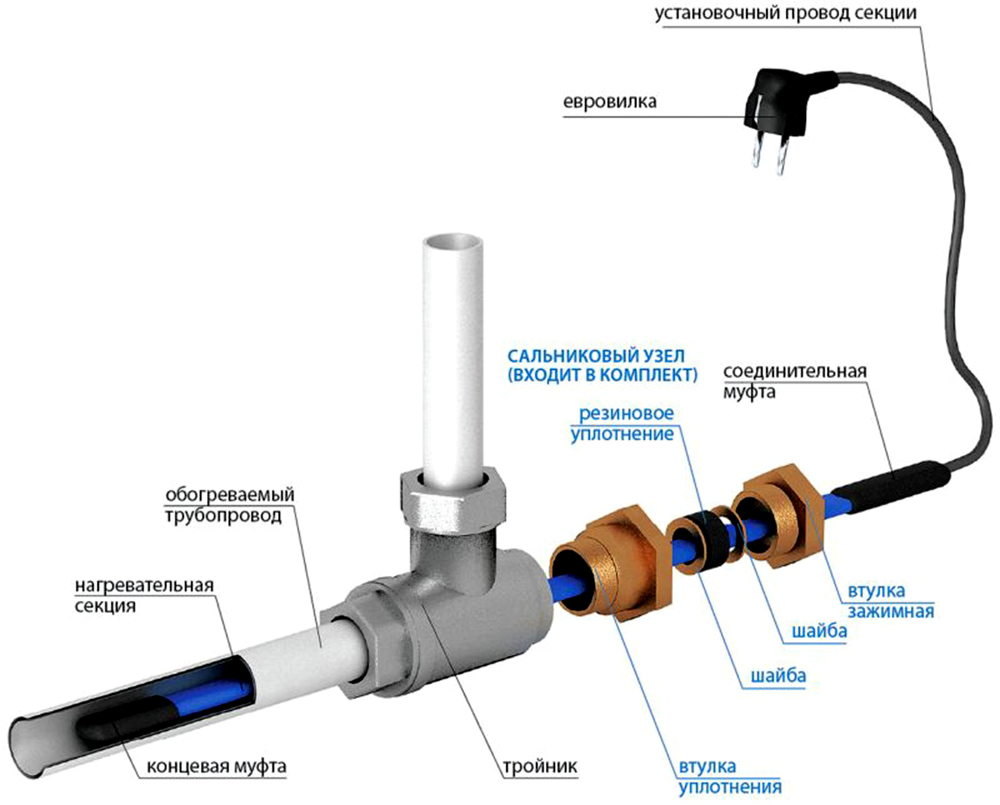

- By installing installation, you need to put a tee. At the same time, all the norms of sealing should be observed.

- In the transition device you need to fasten a special cut.

- In the insertion when installing the heating electrical wiring of the desired length is filled.

- By performing installation, it is necessary to accurately measure the length of the pipe prepared under heating.

- You can not install the cable through the shut-off valve on the pipe.

- The location of the cable set in the pipe is marked with a warning sign.

- Installation should be done very carefully so as not to damage the electrical wire. If the wire was damaged during operation, then it will immediately be changed.

- Sharp edges of the system and threads on some details during the installation you need to make a ribbon. This will prevent damage to the heating wire.

Mounted properly heating cable for water supply inside the pipe for a long time will create an unimportant water source that will function smoothly during cold winter days.

Watch the video

The problem area of \u200b\u200blife support is a private house is a water supply system, since there are many difficulties in terms of water supply, for example, in winter. Under the main obstacle here it is understood that the pipes can simply freeze in the winter. Although they can be placed below the duration of the soil freezing, but it does not save it from problems, since the place of entry of the water supply in the house in any case is critical. In this case, this problem is relatively easily solved if you use the device in the form of a self-regulating cable, which makes it possible to provide constant water without any interruptions associated with low ambient temperatures.

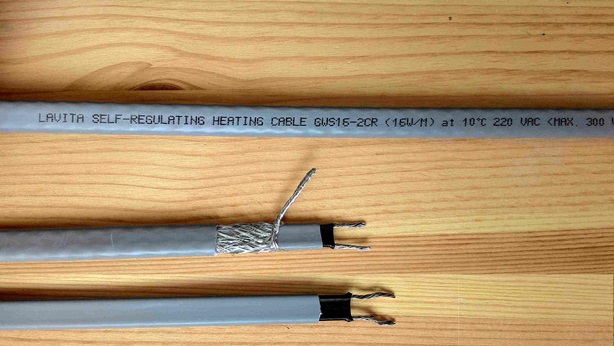

Before you know how to make heating, we learn more about the cable for heating the drainage. The considered view is an electric belt heater, the design of which is provided for the presence of parallel conductors separated by a polymer matrix. This semiconductor matrix is \u200b\u200bable to allocate heat due to the fact that in its middle there is a heating cable for a water supply system that promotes the continuity of heating. The features of this product are as follows:

Principle of operation

The heating cables of the view under consideration, that is, oriented to automatic regulation of the heat released, have a polymer matrix in their composition, which is an element of resistance capable of refractive to counteract the strength of the current depending on the degree of its heating. Directly the heating itself matrix occurs due to the fact that it comes into contact with two conductors who are warm through the current passing through them. When the matrix is \u200b\u200bheated, its resistance increases, and the current value decreases.

In this regard, it is possible to achieve a certain equilibrium between the power of consumption of self-regulating cable and its temperature. For example, the lower ambient temperature leads to greater power isolation, which is also natural and in reverse order. The cable for heating the water supply can be located in a medium that differs in its characteristics in different parts, so the cable temperature will also not be the same.

As a result, it is possible to achieve the effect of self-regulation, when the energy secreted by one wire is not uniform over its entire length. If certain areas are in a cold medium, then there is greater excretion of energy, and if in warm, then less. The same effect avoids overheating of certain sections of the cable, which is ensured by their response to the change in the temperature background.

Circuit current in a self-regulating cable occurs by the matrix in parallel. This provides the ability to connect a voltage of 220 V (working) to the cable without limiting its length. Although it is more theory, since restrictions are still there, but they are more connected with the parameters of the current load and starter current having permissible values \u200b\u200bfor copper tires. Failure to follow these parameters can lead to the destruction of contacts that serve to connect copper tires and a polymer matrix. The value of the system start current exceeds the nominal in two or three times. In this case, the possible length of the sections is from 60 to 100 m, which depends on the type of cable used.

Positive moments of self-regulating cables

Cable classes depending on temperature

Thermocables are customary to be divided into three classes:

- Low-temperature - Suitable as protection of pipeline pipes from freezing, as well as in cases where it is necessary to extend the pipeline of a small diameter. The maximum heating parameter is 65 ° C, and the specific power is 15 W / m.

- Medium temperature - ensure heating of drain pipes, thawing the roof and frozen pipes having an average diameter. It is guaranteed to heat up to 120 ° C with a power of 10 to 33 W / m.

- High temperature - Cables of this species are used in industry, so they are able to heat up to 190 ° C with power from 15 to 95 W / m.

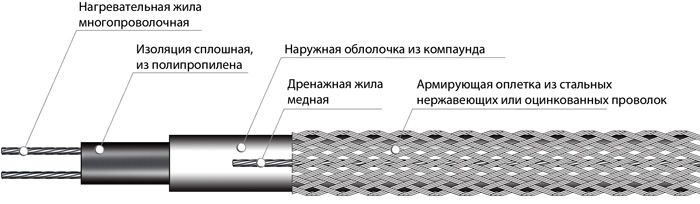

With a braid or without: What is better?

Thermocabages are produced with the presence of a braid or without it, which determines the different characteristics of the final product. A cable that does not have braids is directly the cable itself and only one layer of insulation, which is external. The lack of braid significantly reduces the cost of this product.

In the case of a thermocabel, a supplemented braid, which consists of copper wire, everything changes dramatically - the product acquires new properties. In particular, it becomes stronger and more reliable, and the braid also provides grounding. At the same time, its cost increases significantly.

What power will required?

To buy a thermocabel of high power without justifying this purchase from the point of view of its relevance is an unreasonable waste of money. Equipment must comply with the need. If the capacity of the product remains unclaimed, empty electricity consumption will increase.

To buy a thermocabel of high power without justifying this purchase from the point of view of its relevance is an unreasonable waste of money. Equipment must comply with the need. If the capacity of the product remains unclaimed, empty electricity consumption will increase.

Power selection must be made based on the diameter of the pipe. Larger diameter is a high power of the wire. The specified ratio is not ideal, since there are additional parameters affecting such calculations. For example, the presence and thickness of the heat insulation layer on the pipe ensures a decrease in heat loss, so the cable under these conditions can be chosen less powerful. In relation to a specific range of pipe diameters, we will determine with a sought-after power in each case:

- from 15 to 25 mm - 10 W / m;

- from 25 to 40 mm - 16 W / m;

- from 40 to 60 mm - 24 W / m;

- from 60 to 80 mm and for 110 mm pipes sewage systems - 30 W / m;

- from 80 mm - 40 W / m.

The information provided is enough to correctly determine the purchase of a self-regulating cable, which will save money.

Thermocabel gasket

A self-regulating cable can be installed inside the pipeline or outside. At low temperatures, the installation is impossible to produce, as you can damage the protective layer of the polymer. The minimum allowable temperature value for the installation of the thermocabel is -5 ° C. In the case when the flexibility of the wire is reduced due to the temperature conditions of the external environment, it is carefully unwound and briefly connected to the power grid, which will allow you to restore physical properties of this product. Only then you should start it.

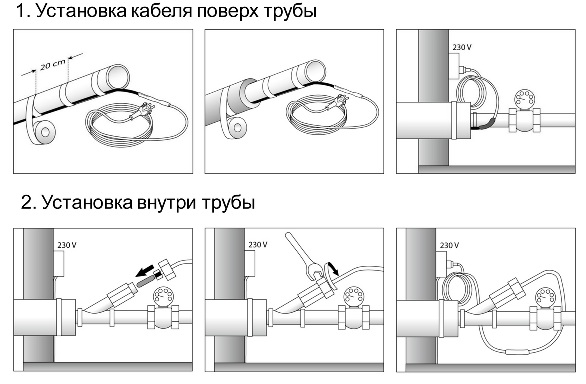

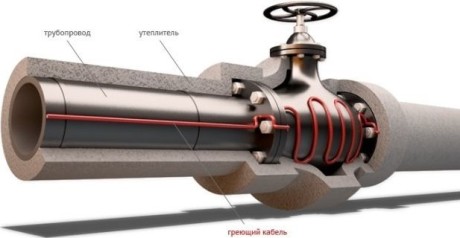

Internal mounting

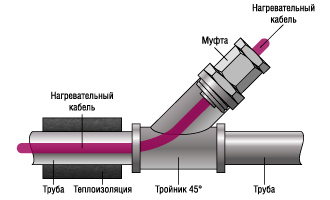

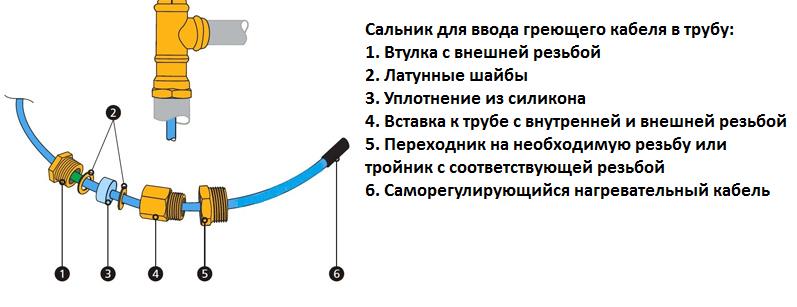

The internal installation method is applied to pipelines having a diameter of up to 50 mm, with limited access. In situations of this kind, the gasket of the thermocabel is made for the entire length of the pipeline. Entering is carried out by means of a gland node consisting of two sleeves and the same amount of washers, including rubber seals.

If an internal heating device is planned to deliver drinking waterIt is necessary to apply a self-regulating cable that is supplemented with an outer shell based on a polymer containing fluoride. Such a thermocabel should also go through the necessary tests for compliance with sanitary and hygienic standards.

If an internal heating device is planned to deliver drinking waterIt is necessary to apply a self-regulating cable that is supplemented with an outer shell based on a polymer containing fluoride. Such a thermocabel should also go through the necessary tests for compliance with sanitary and hygienic standards.

There are the following rules for using the heating cable, capable of adjusting the heating temperature on different sections of its surface:

- must have the same length as the length of the pipeline;

- internal installation cable cannot be used in shut-off reinforcement;

- it is necessary that the pipe has a label about the fact that it has a waterproof heating system;

- the process of entering the wire must be made with extreme caution in order to preserve the integrity of the outer shell;

- before laying the cable, you should take care of the fittings - their edges require closure through the factory tape to avoid damage to the thermokabel.

External mounting

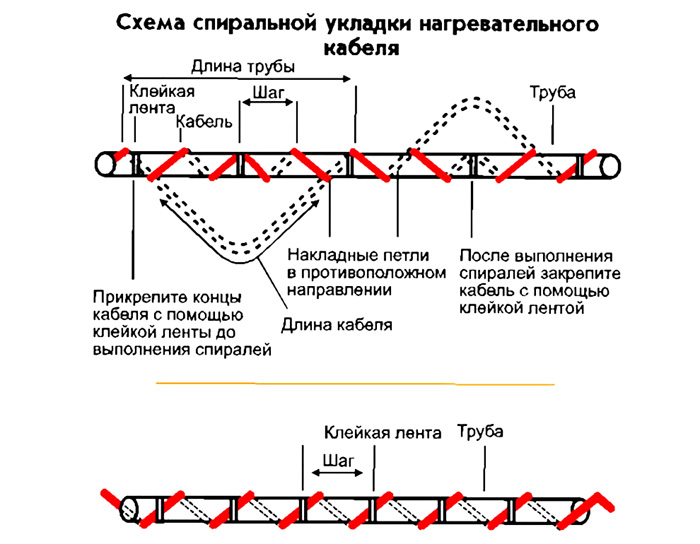

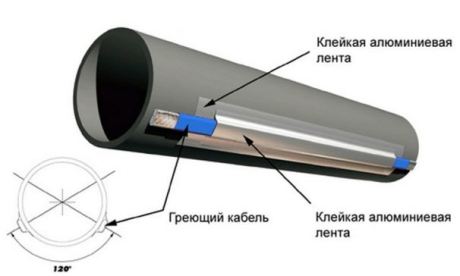

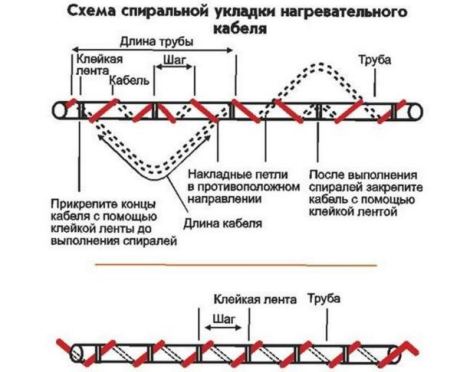

The placement of the heating cable over the pipe is characterized by a fairly wide variability of methods:

- linear - installed on small diameter pipelines in the form of a line running along the pipe;

- parallel - Installation is made on large diameter pipelines or water supply systems that are outdoors; In this case, two or three cables that are parallel to each other are mounted on pipes;

- spiral - the cable as it turns around the pipe along the spiral line with a pitch of the turn, depending on the parameters of the power and diameter of the pipeline;

- wavy - It is used as a replacement of the previous version, caused by the fact that the cable lengths are not enough; Laying the wires for heating pipes of the wavy line involves less consumption of the source material.

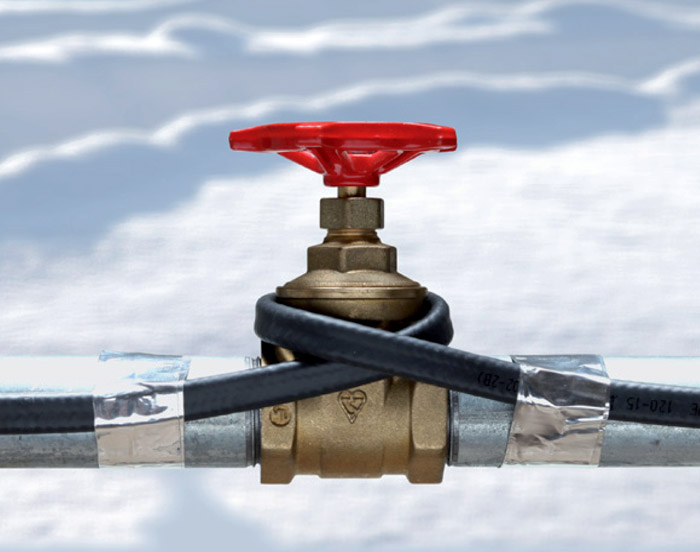

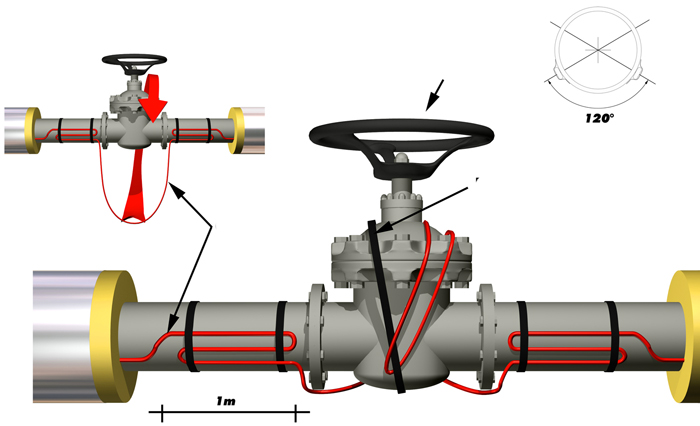

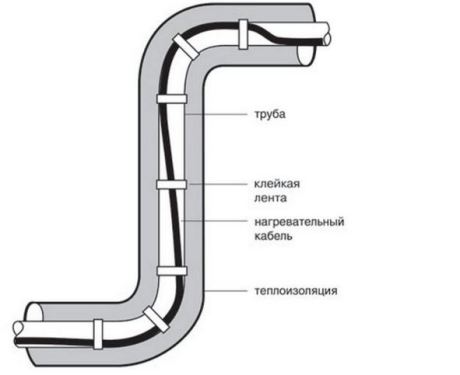

Thanks to the function of self-regulation, the use of the brass cable is allowed, which is used if it is necessary to heat the shut-off reinforcement. External styling should relate to the requirements that would exclude the possibility of abrasion of the wire and other negative impacts of a mechanical nature. This is usually achieved by laying the wire so that it does not interfere with the functioning of the shut-off reinforcement, for example, in the form of valves.

Thanks to the function of self-regulation, the use of the brass cable is allowed, which is used if it is necessary to heat the shut-off reinforcement. External styling should relate to the requirements that would exclude the possibility of abrasion of the wire and other negative impacts of a mechanical nature. This is usually achieved by laying the wire so that it does not interfere with the functioning of the shut-off reinforcement, for example, in the form of valves.

The thermocabel should be relatively rigid to the pipeline through the use of aluminum tape. Upon completion of the installation, the pipeline is mandatory heat insulated to reduce heat loss. Connect the plug cable to the 220-240 V network should be exclusively through the UDO, which is written in the appropriate instruction.

What are the advantages of the cable with the thermostat?

Waterproof heating involves a significant consumption of money, since the heating elements consume electricity. To reduce these costs, you should use cables equipped with thermostators. These devices are good in that they include the heating system, when the temperature drops to +3 ° C, and turn it off when the +13 ° C is reached.

For example, water coming from the well is unlikely to be higher than +13 ° C. As a result, heated pipes in this case will be carried out. round year, and this is ineffective. At the same time, it is asked if there is a sense to warm the water entering into cistern. It is much easier to set the shutdown temperature of +5 ° C and reduce these costs that are heated by drainage.

For example, water coming from the well is unlikely to be higher than +13 ° C. As a result, heated pipes in this case will be carried out. round year, and this is ineffective. At the same time, it is asked if there is a sense to warm the water entering into cistern. It is much easier to set the shutdown temperature of +5 ° C and reduce these costs that are heated by drainage.

As a result, such a positive effect will also take place as an increase in the life of heating cables. The functioning of each thermocable occurs with the development of a resource, which determines how long the product can work without losing its properties. Therefore, fewer hours of operation increases the service life of self-regulating cable.

Installation of heating systems equipped with thermostats, should correlate with a temperature sensor setting, which is determined by some complexity. The sensor must be mounted so that the heat of the heaters does not have any influence on it. It is necessary to use thermal insulation that would serve as a barrier between the sensor and the thermocabel.

The installation of the thermostat itself should be indoors. It uses a house electrical device in the form of a Uzo to connect it. Heating cable consumes little power, because the suitable nominal value of the machine will be 6a, and the nominal RED - 30 mA. Connecting a heating cable is made using special connectors on the housing.

In the conditions of frosty winters, we can not do with conventional thermal insulation, so it is necessary to resort to an additional option that is heating cable inside the pipe. If you use such a cable, you can maintain the required temperature, as well as protect pipes from condensate. In this article, consider the varieties of heating cables and the features of the choice.

About heating cables

Advantages of the cable system

Cable for heating pipes inside - a tool that is already applied quite a long time. In fact, this is an ordinary cable that can adjust electrical resistance, at the same time adjusting and actually heating the cable.

The heating cable is recommended to be used inside the pipe, at minus temperatures it is important to prevent the freezing of water in areas passing outside the house. Includes a cable at a temperature of 5 ° C, thus, the system will continue to protect against freezing as cooling.

At a negative temperature, turn on the system should not be, since in this case it will take time while the frozen liquid will overtake. And all this time will be significantly reduced in the water supply.

Advantages of the cable heating system of pipes:

- Provided properly completed calculations and installation of the heating system, you can prevent pipe freezing during the entire operational period.

- The system is safe enough, it can be used in pipelines with drinking water, allowing you to prevent overheating.

- The versatility of the system is that the warming cable can be used for pipes located underground, inside the building or outdoors. And the cable gasket can be done inside the pipe or on its surface.

- Easy and ease of operation. Such a cable is simply attached to the pipe, then it remains only to stick the plug into the socket, and the system will start its work.

- Efficiency is provided with the possibility of independently adjusting power depending on temperature.

Device of heating cables

The internal heating cable includes several elements connected in one system:

- Plug.

- Cold electrical conductor.

- Conductor hot heating.

- Thermilographer.

With the help of laser spike, the conductors are connected to each other. Ideal protection against moisture penetration, high-temperature and chemical influences provides seamless external insulation heating cable.

The functions that the thermographer performs are as follows:

- With it, the temperature of the pipe is controlled.

- Automatic system launch depending on temperature. If the temperature exceeded 15 ° C, the power is turned off, and if the temperature dropped to 5 ° C, the power turns on, which prevents overheating of the water pipeline and contributes to the maximum energy savings.

Types of heating cable

Heating cables are divided into self-regulating and resistive, depending on which heat generation scheme we are dealing with.

Consider the features of each type:

- Resistive heating cables:

- Divided into zonal and linear. When the current passes through heating veins, linear models are highlighted heat.

- They can be single-core and bile, that is, there are several veins of a spiral or linear form as part.

- It should be noted that the resistive cables are forbidden to cut to get the necessary length.

- Self-regulating heating cables:

- According to its design, similar to resistive, the difference lies in the absence of insulating coating.

- Heat release by different sites The cable may vary, because with increasing temperature, the polymer resistance increases, reducing heat dissipation. This is the effect of self-regulation, which eliminates the possibility of burning or overheating system.

- This type of cable, in contrast to resistive, can be cut on a part of 20 cm length to several meters.

How to choose a heating cable

The heating cable for pipes is chosen depending on the tasks that are planned to be performed by a specific heating system.

For example, for household purposes, for private houses, cottages, country sites, as well as for sewer systems, water supply systems and drainage - to protect the pipes in them from freezing, heathery systems of small sizes.

Such a cable usually has a power of about 50-60 W / m, buy a product with a higher indicator - an empty waste of money. The price of such a product is quite acceptable, and the specified power is quite sufficient to melt the ice and snow, and the selection of the cable with the specified power value is a reliable and economical solution.

Cables with greater power require, respectively, high electricity costs, which leads to an increase in the total expenditure on the operation of the heating cable.

Pay special attention to the fact that today is most common self-regulating cables With two main parameters: operating power and power at rest. The values \u200b\u200bof these indicators must be indicated on the surface of the product.

How to mount heating cable inside the pipe

Heat pipes from the inside with the help of the cable is possible only if the diameter of the pipes is not less than 20 mm.

We list the main nuances when installing heating cables in the pipes:

- Installation of a heating cable inside the pipe as follows:

- at the injection site in the pipe heating cable, a saddle or a tee is installed;

- pipe cutting into the saddle;

- the heating cable is set into the insert.

- The length of the heating cable must be equal to the length of the pipe area, which is planned to heat. It is important to make all the measurements as accurately as possible.

- Putting the warming cable inside the pipe through the shut-off valves is unacceptable.

- It is forbidden to fix the feed cable and the coupling with a penetration of the kit and the gland when the cable is entered into the pipe.

- All works require maximum care and accuracy to prevent damage to the cable shell. Acute elements, such as the threads of the fittings, should be closed at the installation of the factory ribbon.

Be sure to place a preventing inscription in the place where the heating cable was installed inside the pipe.

If the wire is properly correct and work is made taking into account all the recommendations, you will not be disturbed by such problems as the freezing of water supply and a decrease in pressure in winter.

IN country house The problem of freezing water pipes is a fairly frequent problem. This may occur due to severe Russian frosts or improper gasket engineering networks. You can solve this unpleasant task with the help of compulsory heating of water supply networks. Install a cable for heating a tap pipe can even start the homemade master.

The heating system will help to avoid emergency with water supply

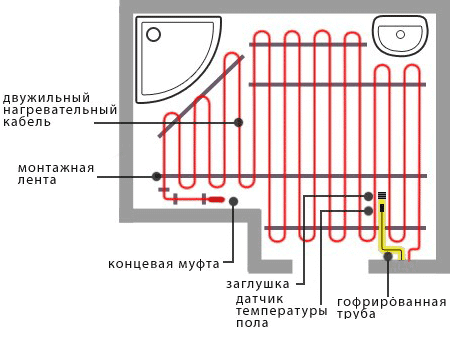

The principle of this heating is quite simple and similar to the operation of warm floors. Suitable for water supply Self-regulating heating cable or resistive. It is paved in the right place and plug into the power grid.

Installation of the heating device is carried out in two ways:

- paved inside the network;

- wound outside.

The resistive heating wire for water pipes is less self-regulating, so it is used more often.

Important! Two-tire wires are used to warm engineering networks. It does not need to be slapped as one-core.

A self-regulating conductor is good because it saves electricity significantly and does not require the installation of the thermostat. Its only drawback is two times higher than the cost compared to the resistive analogue.

Article on the topic:

What are the advantages of such a cable? Is its price justified? And how to mount it correctly? Read in a special publication of our portal.

What situations require the installation of a heating conductor:

- when the work is located outside the house;

- engineering networks are located above the level of the freezing of the soil;

- in some places, the pipeline passes from the underground part to ground;

- communications are held inside the unheated space (attic, veranda).

Note! The laying of the water supply below the primer of the soil does not exclude the probability of an emergency. Water can partially turn into ice and tighten the network.

Water pipe heating allows you to avoid freezing and allows you to maintain the desired temperature all winter period

The cost of resistant wiring begins on three hundred rubles. A self-regulating conductor will cost approximately seven hundred - a thousand rubles.

How to pave a cable for heating a tap

The system of heating engineering networks has several components:

- electric pipe;

- special fasteners, tightly fixing wire on the channel;

- power conductors connecting the warming system with a source of energy;

- additional electrical appliances providing compounds and thermoregulation.

Note! The cable for heating the tap pipe can be heated to a temperature of a hundred twenty degrees, but it should be remembered that such warming can adversely affect plastic materials.

Resistive cable

He has two heating veins, closed in the heat insulator and shielding shell. It works as an ordinary Ten. The main requirement for this device is not to divide it into parts, in this case too many adapters will need, which will significantly complicate the installation.

The resistant conductor will evenly warm the entire water supply network. If some part it stopped functioning, you will have to change the entire system. But the main thing in this system is its low price. The heating cable for water supply outside the pipe is easy to install itself, saving at the invitation of specialists.

Self-regulating wire

This device has a semiconductor matrix that allows you to adjust the temperature of the system under external conditions. The matrix is \u200b\u200blocated between the conductors of the wire. This system allows economically to spend energy, while maintaining the optimal result. This system can be divided into parts without fears.

Mounting cable along the pipe

This type of heating is considered the simplest in the installation. The only thing important condition - The electrocabel must pass under the network. This position will protect the wire from random mechanical damage. In addition, water in the pipeline begins to capture the ice from below, so this type of heating will prevent an emergency. There are several cable laying schemes:

For fixing the wire, you can use construction metallic tape, it will firmly attract the cable to the pipe, and increase its heat transfer. Fastening the cable with ordinary scotch, but is short-lived. When laying a conductor, special attention should be paid to the angular momentum. To live did not break, it is located on the outside of the pipeline.

In the northern regions where strong frosts are observed for a long time, experts recommend winding the heating cable to a spiral-shaped water pipe. The consumption of the veins will be almost twice as much, but the efficiency of such a device will increase by an order.Step one turn - from five centimeters and more.

Tip! To wind the wire in a hard-to-reach place, a lot of turns are wound at first, and then they are spreading in reverse order.

To prevent overheating of the system on a resistant cable, you need to install a temperature sensor. It is recommended to install in the very murdered place, far from the heating core. The location of the installation is winding with metallic scotch.

Warming cable for water supply inside the pipe

Laying the heating wire inside the water pipeline is a less labor-intensive process. It is possible to choose only when engineering networks have been mounted long ago and are not available for external heating arrangement.

Cons in a similar method:

- significantly decreases the internal volume of the pipeline;

- after some time, the wire will begin to overgrow lime raid and can buy water pipes at all;

- reliability of the system contour decreases due to the need to use tees;

- installing the in-pipe system can only be installed on direct plots of water supply.

How to install the heater inside the pipeline:

- The gland is put on the wire, the tee is mounted at the wire input, through which the cable is served.

- The wire pushes up to a particularly cold place, which represents emergency danger.

- The gland node should be sealed, spin and enhanced.

Connecting the cable to the source of energy

To insulate the end of the cable, a heat shrinkage is used, which will protect the wire from the penetration of moisture. How to connect the heating of the water supply, is shown in detail on the video below.

Helpful information! Most heating systems work only at a cable length until fifty meters.

Connecting a heating cable (video)

Gasket of thermal insulation

In order to increase the efficiency of the system, it is necessary to cover the water pipe insulating material.

The thickness of the insulation should be at least two centimeters. The larger the diameter of the pipe, the thicker it is necessary to choose the heat insulator.

- For the efficient operation of the cable for heating the tap pipe, it is important to correctly calculate its power. Make it yourself is difficult, so it is better to contact the specialists. There are tables and formulas for calculating the heat loss pipe.

- Calculation of heat loss should include average temperatures of the region.

- If supports or reinforcement fasteners are installed on the pipe, it is necessary to increase the number of cable turns in these places.

Outcome

The electrocabel for heating the water supply system will help to avoid freezing and breaking pipes into laid frosts.

It is not difficult to mount such a heater, but the recommendations of specialists on the settlement should be taken into account required power heater.

The usual wire works constantly at maximum power, and self-regulating heating cable changes the intensity of heating depending on the ambient temperature and surface. Moreover, in different areas there may be different intensity depending on the resistance and strength of the current. We understand the work of cable systems, their advantages and disadvantages, is it built with your own hands and is it worth it for it.

The structure of self-regulating cable

Self-regulating cables are always two-housing (unlike ordinary). There is a semiconductor matrix between these veins - it also regulates the resistance and current strength.

The braid protects the elements from electromagnetic radiation and plays the role of the earthing, and the outer shell protects the cable from the effects of mechanical nature.

The principle of operation of self-regulating cable

The cable operation is based on the properties of semiconductors with increasing temperature to increase resistance, which reduces current strength. Below the current is less than the temperature of heating and power consumption.

In different parts of the cable, the heating intensity can be different. For example, one of the rods of the roof in the shade, and the second in the sun - the cable will heat the shaded side of the roof intense than the sunny rays. However, he will warm in any case, albeit slightly. So that this does not occur at above +5 and the cable did not disappear the operating resource ahead of time, the thermostat is introduced into the system, turning off the power supply when the threshold temperature is exceeded.

Cable heating

It is economical, convenient and works well. Cable heating apply in many areas.

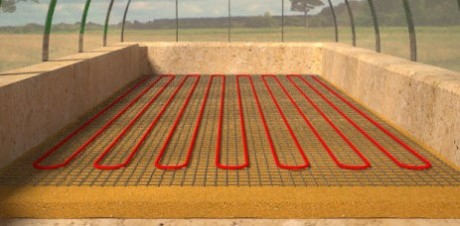

- "Warm floor": wires are placed under flooring or directly in a concrete screed (by the way, the connection of warm floors to the hot water supply is prohibited). A competently mounted system is capable of performing heating functions.

- Heated solid solutions: Concrete weight requires certain conditions for the entire period of hardening, and the heating elements create these conditions in part temperature mode. Wires are fixed to the reinforcement (they use the cheapest) - they remain in the progress.

- Heated Mirrors: The cable system placed on the reverse side opposes the formation of condensate, which makes it difficult to use mirrors.

- Pipelines: Cables are placed from one or more sides of the pipe or weigh it on the helix. Often it is much more profitable to use the wire for heating pipes than to strengthen thermal insulation.

- Technological fluid - maintenance of temperature (in demand in the oil, chemical, food industry).

- Agriculture: HEATIC SUPPLIED Heating is suitable using cable systems.

- Cleaning toes and snow: Heating wires prevent ice formation, icicles by constant heating of the roof, drainage, eaves.

IN residential buildings Private sector Cable systems are used for heating:

- roofing;

- drainage;

- rampus and stairs;

- pipelines - water supply and drainage (including autonomous), storm sewage and drainage system.

Heating roof and drainage

Heating elements are placed in endows, chutes, directly on the roofing coating around the perimeter, in the drainage pipes (up to the taps to the Livnevy - throughout the water path), around the perimeter mansard windows (if there are such), in places of conjugation. The system consists of cables, junction box, thermostat, sensors (temperatures, precipitation, water).

In the grooves and endows, the cable is paved along and fasten with a special aluminum mounting ribbon or via brackets. In the drainage pipes it will be raised inward.

Video: Anti-icing system for roofing

Water pipe heating

Heating cable is placed inside the pipe or outside. Both types of installation are good in something, and something losing each other - the choice depends on the tasks, the location of the pipeline, the diameter of the pipes and other factors. Secure cable on external surface Pipes can only be in the process of laying the pipeline, on the inner - at any time.

Outdoor installation

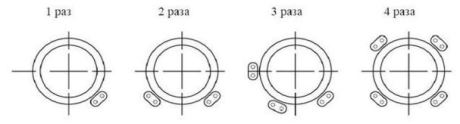

External wires can be somewhat - from 1 to 4. Single laid along the contour from below.

Multiple Conduction Scheme

Fasten predominantly aluminum scotch - it increases the heat transfer, convenient and reliable (more protection against damage, more effective heating: Water freezes with Niza).

Mounting circuit on pipeline rotations

Spiral is another way of laying an external cable. It is wound on the pipe (step - 5 cm) and fasten the mounting ribbon, as shown in the diagram below. Wires required more than the length of the pipeline, 1.7 times, but heating is much more efficient and faster. IN hard to reach places The cable is wound with the allowance, then the pipes formed with the loops just wipe.

Separate hubs of the pipeline (supports, shut-off valves and so on.) Warmly removed in a larger volume, so cable is placed on them in such a way:

After installing the heating system, thermal insulation are arranged. The cables are laid on the sewer pipelines (including lavetyvy).

Internal mounting

Inside the pipes, the heating cable is filled only if otherwise not possible. Such styling has significant drawbacks:

- reducing the lumen of pipes;

- inevitable fascination of the cable of the raid;

- reducing the reliability of the contour by adding another point - tee;

- the inability to carry out the wire through the shut-off valves, tees.

There are advantages: direct contact of the heater with a liquid increases the effectiveness of heating, which reduces energy consumption; Repair does not cause difficulties (the cable is simply pulling and replaced).

Procedure for mounting wires inward pipe:

- installation on the heating cable of the gland node;

- installation of a tee for entering the heater in the pipeline;

- cabling;

- sealing the gland node.

Characteristics of cables for heating water pipes

- Power. It is enough power 5-25 W / m: for an underground pipeline, cable inside - 5 W / m, for underground, cable outside - 10 W / m, for overnight - 25 W / m.

- Working temperature. Apply exceptionally low-temperature cables (up to 65 degrees).

- Features of application. There are only two groups - technical and food cable. If you pave outside, use technical, if inside - food.

Inside the pipe you can make only a cable certified as food. In many stores it is written - food. Require a conformity certificate (without an application containing detailed information and codes OK 005 and TN VED, certificate is invalid).

Location of heating cable on a pipe

How to connect heating cable to the network

There is nothing complicated for specialists in connecting electrical heating cable. A person of the uninitiated we do not recommend carrying out electrical work with your own hands, although the instructions are more than enough.

Video: Connecting a heating cable to the network

We offer for viewing a video - a visual allowance for "cutting" self-regulating cable.

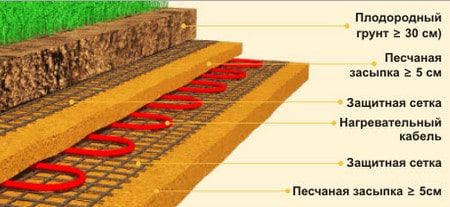

Heating Teplitz

In the installation schemes of the warm floor and the heating system, the differences are practically no difference. In fact, they mount the same floor, but under the other " flooring».

The heating wire is laid on the protective grid located on the sand pillow. From above placed another sandy layer, it is a protective grid, then a fertile soil. It turns out a multi-layer "Pie".

"Pie" looks somewhat different when they use a flat sampling tape. In this case, the first arrange thermal insulation, and metal grid Lake only one layer.

If there is no possibility to mount the system under the soil, the heating elements are placed on the walls of the greenhouse.

Advantages and disadvantages of cable heating

Benefits:

- ease of installation;

- low weight;

- minor energy losses;

- small cross-section of wires, due to which the dimensions of heated designs are almost no increase.

Disadvantages:

- fire hazard

- weak electrical safety.

Competitive self-regulating cables reduce the flaws to zero if the installation was carried out by specialists in full compliance with the rules and recommendations of the manufacturer (the bend angle is specified in the instructions for sections). Electrical installation (no matter how easy it is) should conduct exclusively professionals.

As for his own installation, they say even a hare can be learned to smoke, and in 5 minutes of watching a video to make an electrician from a librarian / cake / shoemaker - and is easier. We did not have to meet smoking hares, but the burnt houses come across to the offensive often, and the preferential cause of disaster - the mistakes of the home-grown "electrical installations".

Self-heating cables are often selling ready-made sections. It remains only to include - that is, it is trite to introduce a plug into the outlet. The difference in price is insignificant, and in comparison with the cost of recovery (if it is generally possible) the structure after a fire - and not at all insignificant.