Which length boards are. Standard Sizes and Types of Bruus

Building material, widely used since a long time and to date. A vivid example of this is the superbly preserved monuments of ancient architecture throughout Russia. If earlier the wooden bar was called log processed (sharply) from four sides before receiving the same section along the entire length, then the modern production of this building material It has long been not limited to its classic view and form.

What will we talk about:

Types and forms

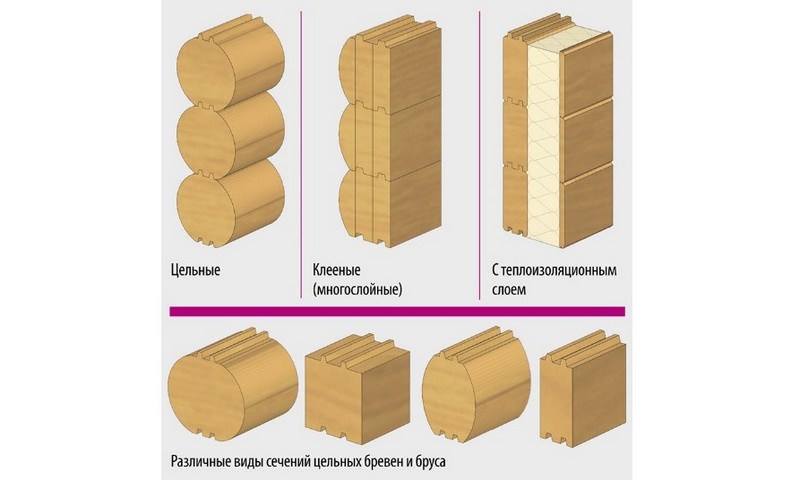

Distinguish three main types wooden bar:

- solid (classic, smooth) bar;

- bar profiled;

- bar wooden glued.

Their form is only a square and rectangular for all three types of timber, with a smooth surface of all four ribs. So with various in the form and dimensions of the grooves and protrusions on two (opposite) sides of the profiled timber. Photo. The glued bar can be both solid and treated with a profile plane.

Wood

By virtue of its natural properties and characteristics, not every tree can serve as a basis for obtaining a construction bar from its barrel. The main rocks of wood for the construction bar are:

- pine;

- fir;

- larch;

- cedar.

Much less often use: aspen and birch. Wood of these breeds despite their low cost, use only for auxiliary elements.

Dimensions, section GOST

At its length wooden beams (timber) are from three to nine meters, but the mains are considered to be 300 - 600 cm. As the most optimal dimensions For transportation, storage and construction. In some cases, the bar can be made according to individual sizes (up to 9 m). This is mainly related to standard typical buildings from the profiled timber.

The dimensions of the section of a wooden bar start from 100 mm (10 cm) and reach 300mm. With a square shape of the section, this is:

- 100 x 100 mm;

- 150 x 150 mm;

- 200 x 200 mm;

- 300 x 300 mm.

And correspondingly:

- 100 x 150 mm;

- 150 x 200 mm;

- 250 x 300 mm;

- Or other size (100 x 200 mm, etc.).

Standard sizes of a wooden bar for state standards (GOST) are required for all enterprises producing such products and are listed in the following table:

- GOST 8486-86 "Timber coniferous rocks»;

- GOST 2695-83 "Lumber of hardwood lumber";

- GOST 23431-79 "Wood. Building and physical and mechanical properties. Terms and Definitions";

- GOST 18288-87 "Production sawmill. Terms and Definitions";

- GOST 24454-80 "Softwood sawn timber. Sizes. "

In addition to the size of a wooden bar for GOS, there are a number of tables with standards for its fortitude, humidity, properties, and so on.

Technologies for the production of wooden, construction bar

Whole bar

Today, due to the low cost, the most popular type of product. Low (relatively) price is formed due to sufficiently cheap and simple equipment used for its production. Availability and a wide range of applications not only in the construction of houses (bath, pavilions, etc.) make this material to the leader of sales.

Bar wooden profile (profiled)

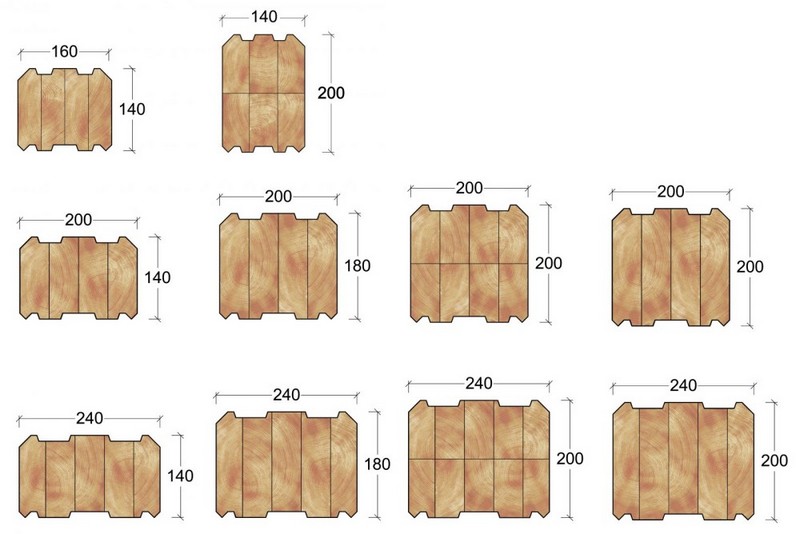

As well as classic (solid) is made from whole logs, according to the same size and sections of the wooden bar specified in the above table. With one but essential difference. Two sides, side, such a bar - smooth. A 2 (top, bottom) possess a groove and protrusion (comb) for dense alignment. The number and form of grooves (ridges) depend on the width of the bar and constructive features General buildings from it. Thus, at a higher cost in comparison with a solid, the profiled bar is an order of magnitude more economical. When working with it, there is no need to additionally seal (cavalo) walls. The clutch of the bar is rising. And that the construction process itself is significantly reduced by time.

Wooden glue bar

Modern technological method of manufacturing a bar, which appeared just over 30 years ago. The main thing a distinctive feature The glued bar is that it does not require solid tree trunks. Depending on the required thickness, n n number of pressure boards are used. As an example, the production of plywood can be caused. The glued bar, not only does not lose any qualitative characteristics in comparison with the analog (solid), on the contrary, receives a number of differences. Such as increased resistance to deformities and strength. Because of the additional cost in production (glue, press) glued wooden bar, as a rule, is produced in profiled forms.

Advantages of construction from a wooden bar

As the benefits of house-building from a wooden bar of various types, first of all, it should be noted its belonging to the so-called green construction technologies. Technologies that cause minimum harm environmentAs at the time of building the building, its operation, and in the case of its dismantling and disposal. At the construction of a house with a finished foundation takes from three to four weeks.

When using a profiled or glued bar, there is no need for an external and interior decoration. The heat-insulating and noise-eyed properties of wood are known for centuries and do not need additional descriptions. The main problem of the past is a fire danger, mold and various bugs - woodworks, today is easily eliminated with the help of modern refractory and biological impregnations.

The service life of wooden buildings is not inferior to stone houses, and in many economic indicators surpasses them. Natural tree creates indoors its microclimate, which is beneficial to the physical health of residents.

Almost everyone is based on standardized dimensions, in particular, on the standard size of the timber in the process of designing and building wooden structures and industrial products. Why is it so important standardization in such an industry like woodworking?

The need for standardization

Humanity has long come to understand that it is necessary to voluntarily fulfill certain rules and requirements in the process of its production activities, because it is:

- simplifies the exchange of information necessary in the design, design and manufacture of finite structures and structures;

- makes it possible to use typical measuring equipment;

- allows you to use the same type machining equipment during the preparation of wood, its pretreatment, storage and transportation;

- allows the use of unified techniques for calculations during design;

- allows preliminary calculations of places for storage, the use of rolling stock;

- standardized lumber dimensions provide an opportunity to easily calculate the volume and weight, which is extremely necessary for shipping and warehousing planning;

- statistical data grouped by type of wood in accordance with standards allow long-term and strategic planning related to the production of individual rates of sawn timber.

Lumber, depending on the tree of wood, from which they are manufactured, are divided into coniferous and deciduous.

Wood quality is determined by the presence of bitch, inclusions, rotors, etc. Wood coniferous breeds in quality is separated by 5 varieties, and hardwood wood is 3 grades.

Wood quality is determined by the worst item and labeled on the ends. The letter "O" denote the highest quality products.

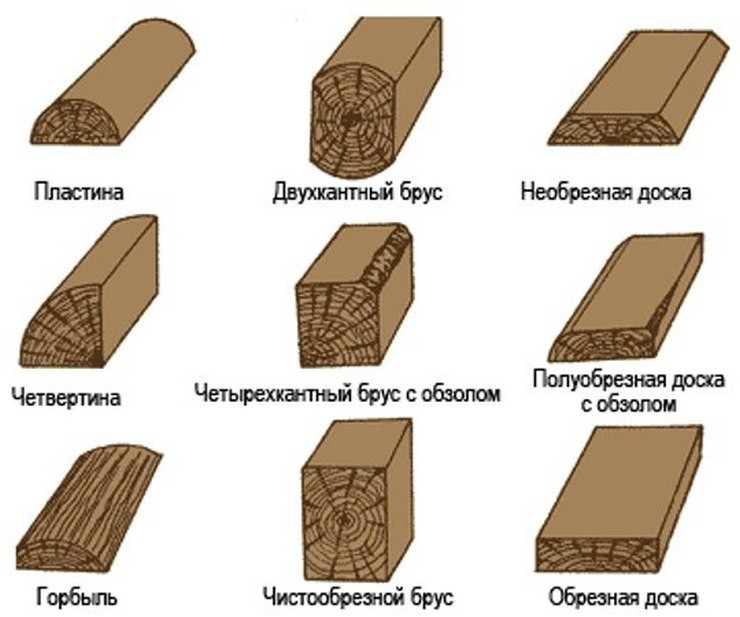

Depending on the cross section shape, all sawn timber are divided into several large groups:

- Gorny. It is made from the side part of the log, and, accordingly, has 1 damp side.

- Sleeper. The type of sawn timber obtained by cropping of all 4 side surfaces, but without formation of faces.

- Bar. It is manufactured from the central part of the log, and, accordingly, has all 4 suited parties. The cross section of the bar is determined by the ratio of width and height less than 2.

- Board. It differs from the bar as a ratio of width and height greater than 2. In accordance with the classification method, according to the processing method, it is divided into one-sided edged, unedged and edging.

In accordance with the existing standards for our country (similar standards exist all over the world), all sawn timber are separated by processing method on the following:

- unilaterally edged lumber - wooden billets, in which 3 surfaces are formed by sawing, and the fourth retained the natural shape;

- crew sawn timber are such wooden blanks, in which all 4 sides are formed by sawing;

- unedged are billets, in which 2 parties are formed by a sawing, and 2 sides have retained a natural form.

Brous varieties

The timber, as an element of the construction structure, is characterized by the ratio of the width and height of the cross section of less than 2. Standard bar In accordance with GOST has a width selected from the following dimension range: 50, 60, 75, 100, 130, 150, 180, 200, 220, 250 mm. But the following sizes are most in demand: 100x100 mm, 150x150 mm, 200x200 mm. It is under these standards that metal fasteners are made, the cutting tool is calculated.

According to the manufacturing method, the following varieties of timber are currently distinguished:

- Whole timber. It is made from the central part of the tree. The most traditional manufacturing technology of the longitudinal sawing of a wooden billet, at which 4 unedged boards is formed: a hill and the central part.

- Rounded timber. It is produced in a similar way, but this product is not rectangular. By appearance A pinned timber resembles a sleeve, but has a big length. Rounded bars are used as bearing elements of wooden structures.

- Glued bar. Modern technology Manufacturer first applied by Finnish woodworking specialists. Wooden blank blooms on several thin boards - lamellas. These lamellas unfold relative to each other in such a way as to minimize the warping in the drying process. After that, everything is sick under the press. Such a glued bar is practically not prone to temperature changes, the counter direction of the board compensates for it.

- Thermobus. A modern high-tech solution in which thermal insulation and mechanical properties are combined. Constructively, the thermobrus consists of 2 boards interconnected by polyurethane filler. To ensure mechanical strength through a certain space between the sidewalls, a special insert is pasted.

- Batch bar. Represents wooden designCollected from the thermobrus. The compound is performed using special polyurethane ties, which for a long time retain the ability to compensate for temperature expansions.

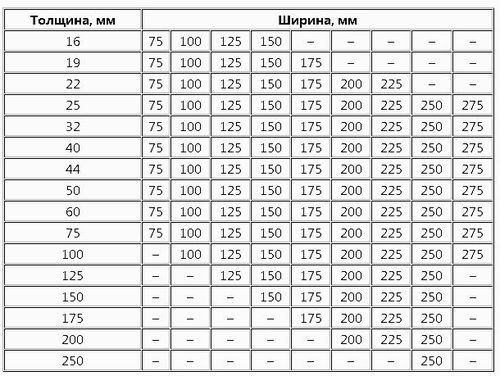

During construction, so far one of the most sought-after materials - edged board. When buying, you can sell lumber to the size you specified. But most often the size of the boards comply with the standard GOST. For edged boards of coniferous breeds, this standard is called GOST 24454-80. It is a table in which all possible thickness combinations are indicated, the width of the board. Standard Board Length - 6000mm (6 meters).

Dimensions of boards according to GOST 24454-80

| Thickness | Width | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 16 | 75 | 100 | 125 | 150 | - | - | - | - | - |

| 19 | 75 | 100 | 125 | 150 | 175 | - | - | - | - |

| 22 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | - | - |

| 25 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 32 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 40 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 44 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 50 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 60 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 75 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 100 | - | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 125 | - | - | 125 | 150 | 175 | 200 | 225 | 250 | - |

| 150 | - | - | - | 150 | 175 | 200 | 225 | 250 | - |

| 175 | - | - | - | - | 175 | 200 | 225 | 250 | - |

| 200 | - | - | - | - | - | 200 | 225 | 250 | - |

| 250 | - | - | - | - | - | - | - | 250 | - |

We simply use the table. Let you need a board with a thickness of 75mm. This means that the width of such a board can be 75, 100, 125, 150, 175, 200, 225, 250 and 275 millimeters. Or another example - you want to buy a 125mm width board. So the thickness of such a board can be 16, 19, 22, 25, 32, 40, 44, 50, 60, 75, 100 or 125 millimeters. For construction work It may be necessary to determine and.

Board size in

First you need to understand which board is called an inch. We know that in one inches about 25 millimeters. Therefore, the board with a thickness of 25 mm and began to call an inches. And mean, using the table of the size of the board, we can see that the incision board has a size (width) 75, 100, 125, 150, 175, 200, 225, 250 or 275mm.

Fireboard size

Chubbed board

Here it is necessary to clarify. Most often for the floor, the tipped board is used (see photo). In the event that an unpleasant board is used, its dimensions can be determined from the table above.

Typical size board sizes:

- width 100mm - 105mm;

- thickness 30mm - 35mm;

- length 4500mm - 6mm (4.5 - 6 meters).

[Estimates: 16 Average: 4.4]

When building a house from a bar, first of all, it is necessary to calculate the amount of material that we need. For accurate calculations, it would be good to know the standard dimensions of the timber and edged board - the most commonly used lumber in the country house-building.

Usually, the construction bar has the following dimensions:

- 150 × 150 mm;

- 100 × 150 mm;

- 100 × 100 mm;

The small timber has dimensions of 40 × 40 mm and 50 × 50 mm.

The standard length of the bar is 6 meters, and the larger length of the bar may be only if you ordered it specifically on the saw. When ordering a timber for more than six meters long, it is necessary to take into account possible difficulties in its transportation, since not all types of transport can provide the necessary capacity.

Standard cutting board sizes are 100 and 150 mm wide and 50, 40 and 25 mm in thickness. Like a bar, the standard of the board length is 6 meters.

The timber and the edged board is made mainly of coniferous wood growing in the region, which is due to economic feasibility. The most commonly used in the construction of lumber from pine and spruce, as well as aspen and birch, as the cheapest. Slightly more road bar and blackboard from fir and larch. Basically, cheap sawn timber uses for the basis of construction, frames and bearing walls.

For interior decoration Timber of mahogany, beech, ash, oak and linden are used. Of course, these materials are already more expensive, but much more presentable looks, they are more interesting and harder to process and they have an attractive texture.