Cubature edged board table. Standard sizes and types of timber

Building material, widely used from ancient times to the present day. A striking example of this is the magnificently preserved monuments of ancient architecture throughout Russia. If earlier a wooden beam was called a log processed (rounded) from four sides to obtain the same section along the entire length, then modern production of this building material is no longer limited by its classic look and shape.

What will be discussed:

Types and forms

There are three main types wooden beam:

- one-piece (classic, even) timber;

- profiled timber;

- glued wooden beams.

Their shape is only square and rectangular for all three types of timber, with an even surface of all four ribs. So it is with grooves and projections of different shapes and sizes on two (opposite) sides of the profiled bar. Photo. Glued laminated timber can be either solid or processed with a profile plane.

Wood

Due to its natural properties and characteristics, not every tree can serve as the basis for obtaining a building bar from its trunk. The main types of wood for construction timber are:

- Pine;

- fir;

- larch;

- cedar.

Much less commonly used: aspen and birch. The wood of these species, despite their low cost, is used only for auxiliary elements.

Dimensions, section GOST

By its length wooden beams(timber) are from three to nine meters, but the main lengths are considered to be 300 - 600 cm. As the most optimal sizes for transportation, storage and construction. In some cases, the timber can be made according to individual dimensions (up to 9 m). Basically, this applies to standard typical buildings made of profiled timber.

The dimensions of the cross-section of a wooden bar start from 100 mm (10 cm) and reach 300 mm. With a square sectional shape, this is:

- 100 X 100 mm;

- 150 X 150 mm;

- 200 X 200 mm;

- 300 X 300 mm.

And correspondingly:

- 100 X 150 mm;

- 150 X 200 mm;

- 250 X 300 mm;

- Or another size (100 X 200 mm, etc.).

Standard sizes wooden beams according to state standards (GOST) are mandatory for all enterprises producing such products and are indicated in the following table:

- GOST 8486-86 "Lumber conifers»;

- GOST 2695-83 "Sawn hardwood";

- GOST 23431-79 “Wood. Structure and physical and mechanical properties. Terms and Definitions";

- GOST 18288-87 “Sawmill production. Terms and Definitions";

- GOST 24454-80 “Softwood lumber. Dimensions ".

In addition to the size of a wooden bar according to GOST, there are a number of tables with standards for its grade, moisture content, properties, and so on.

Technologies for the production of wooden, construction timber

Solid timber

Today, due to its low cost, it is the most popular type of product. Low (relatively) price is formed due to the rather cheap and simple equipment used for its production. Availability and a wide range of applications not only in the construction of houses (baths, pavilions, etc.) make this material a leader in sales.

Profile timber (profiled)

Like the classic (solid), it is made from whole logs, according to the same dimensions and sections of a wooden beam indicated in the table below. With one but significant difference. The two sides, lateral, of such a bar are even. And 2 (top, bottom) have a groove and a protrusion (ridge), respectively, for tight alignment with each other. The number and shape of the grooves (ridges) depend on the width of the timber and design features general construction from it. Thus, at a higher cost in comparison with solid, profiled timber is an order of magnitude more economical. When working with it, there is no need to additionally seal (caulk) the walls. The adhesion of the timber to each other increases. And what is not unimportant, the construction process itself is significantly reduced in time.

Glued wooden beams

A modern technological method of manufacturing timber, which appeared a little over 30 years ago. The main distinctive feature glued laminated timber is that solid tree trunks are not required for its production. Depending on the desired thickness, N is used, the number of pressure glued boards. An example is the production of plywood. Glued laminated timber, not only does not lose any quality characteristics in comparison with the analogue (solid), on the contrary, it receives a number of differences. Such as increased resistance to deformation and strength. Due to the additional cost in production (glue, press), glued timber is usually produced in profiled forms.

The advantages of building from timber

As the advantages of housing construction from a wooden beam of various types, first of all, it should be noted that it belongs to the so-called green building technologies. Technologies that cause minimal harm environment, both at the time of construction of the building, its operation, and in the case of its dismantling and disposal. It takes three to four weeks to build a house with a finished foundation.

When using profiled or glued timber, there is no need for external and internal finishing. The heat-insulating and sound-absorbing properties of wood have been known for centuries and do not need additional descriptions. The main problem of the past - fire hazard, mold and various bugs - woodworms, today it is easily eliminated with the help of modern refractory and biological impregnations.

The service life of wooden buildings is not inferior to stone houses, and surpasses them in many economic indicators. Natural wood creates its own microclimate inside the premises, which has a beneficial effect on the physical health of the residents.

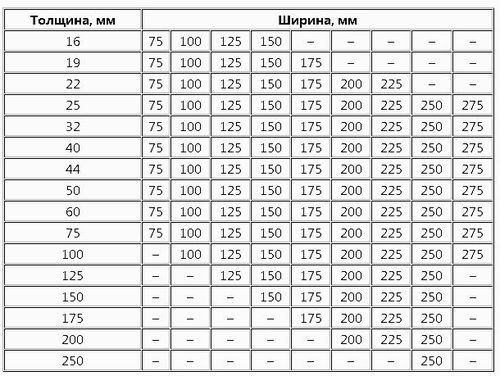

During construction, one of the most demanded materials is still edged board. When buying, you can be sold lumber in the size you specify. But most often the dimensions of the boards correspond to the GOST standard. For edged boards of coniferous species, this standard is called GOST 24454-80... It is a table showing all possible combinations of board thickness and width. The standard length of the board is 6000mm (6 meters).

Sizes of boards in accordance with GOST 24454-80

| Thickness | Width | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 16 | 75 | 100 | 125 | 150 | - | - | - | - | - |

| 19 | 75 | 100 | 125 | 150 | 175 | - | - | - | - |

| 22 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | - | - |

| 25 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 32 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 40 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 44 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 50 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 60 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 75 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 100 | - | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 125 | - | - | 125 | 150 | 175 | 200 | 225 | 250 | - |

| 150 | - | - | - | 150 | 175 | 200 | 225 | 250 | - |

| 175 | - | - | - | - | 175 | 200 | 225 | 250 | - |

| 200 | - | - | - | - | - | 200 | 225 | 250 | - |

| 250 | - | - | - | - | - | - | - | 250 | - |

The table is easy to use. Suppose you want a 75mm board. This means that the width of such a board can be 75, 100, 125, 150, 175, 200, 225, 250 and 275 millimeters. Or another example - you want to buy a 125mm wide board. This means that the thickness of such a board can be 16, 19, 22, 25, 32, 40, 44, 50, 60, 75, 100 or 125 millimeters. At construction works you may need to define and.

Inch board size

First you need to understand which board is called an inch. We know that there is about 25 millimeters in one inch. Therefore, a board with a thickness of 25 mm was called an inch. And that means, using the table of board sizes, we can see that the inch board has a size (width) of 75, 100, 125, 150, 175, 200, 225, 250 or 275mm.

Floorboard size

Tongue-and-groove board

A clarification is needed here. Most often, a grooved board is used for the floor (see photo). If a non-grooved board is used, then its dimensions can be determined from the table above.

Typical floorboard dimensions:

- width 100mm - 105mm;

- thickness 30mm - 35mm;

- length 4500mm - 6mm (4.5 - 6 meters).

[Ratings: 16 Average: 4.4]

When building a house from a bar, first of all, it is necessary to calculate the amount of material that we need. For accurate calculations, it would be good to know the standard dimensions of the timber and edged boards - the most commonly used lumber in suburban housing construction.

Typically, a building beam has the following dimensions:

- 150 × 150 mm;

- 100 × 150 mm;

- 100 × 100 mm;

Small timber has dimensions of 40 × 40 mm and 50 × 50 mm.

The standard length of the bar is 6 meters, and the bar can be longer only if you ordered it specially from the sawmill. When ordering a timber longer than six meters, you should take into account possible difficulties during its transportation, since not all types of transport can provide the required capacity.

The standard sizes of edged boards are 100 and 150 mm in width and 50, 40 and 25 mm in thickness. As with the timber, the standard for the length of the board is 6 meters.

Beams and edged boards are made mainly from coniferous wood species that grow in the region, which is due to economic feasibility. Most often used in construction are pine and spruce lumber, as well as aspen and birch, as the cheapest. Slightly more expensive beams and boards made of fir and larch. Basically, cheap lumber is used for the base of the building, frames and load-bearing walls.

For interior decoration lumber is used from mahogany, beech, ash, oak and linden. Of course, these materials are already noticeably more expensive, but they look much more presentable, they are more interesting and more difficult to process and they have an attractive texture.