Facing walls by boards - an example with a photo. How to use a tree for decorating walls in the bedroom or for lining of individual elements from the uncircumcised board The types of finishing board

This is a board with a coarse, rough surface, which is obtained as a result of a tonon of sawing or milling. The paint for such a non-smooth surface clings better, so the la paining coating serves longer. Our warranty on such a painted finishing board is 5 years.

Technological process Painting Scandinavian boards:

Priming Aqua Primer 2907 / Teknol 3881 (brush machine)

- Application of the 1st layer of Paint Nordic Eco 3330 (brush machine)

- Application of the 2nd layer of Paint Nordic Eco 3330 (brush machine)

When painting this facade board The initial and interlayer grinding is not performed, so the cost of such a board is cheaper than painting smooth, plane products, represented in the next section. Such a paradox is a board cheaper, and durability is higher!

| Dimensions, mm. | Painting | Price per m2. |

| AV / C | ||

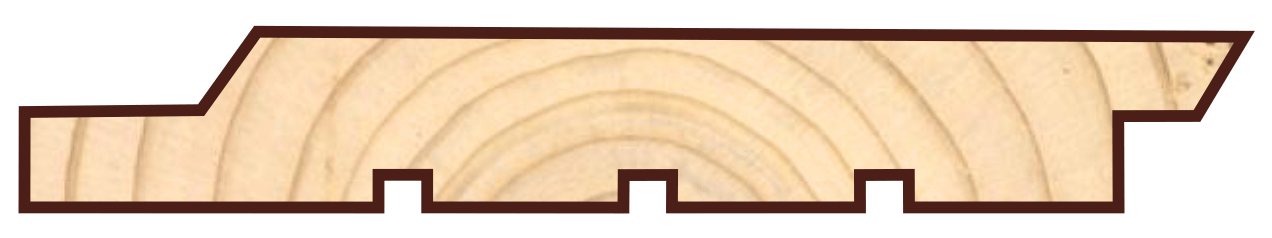

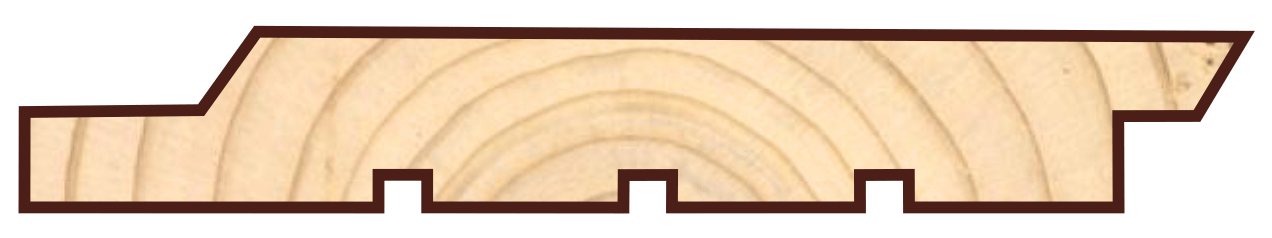

| ProfileUYV. | ||

| 21*145(135)*6000 21*145(135)*4800 | Without painting | 540 rub. / 290 rubles. |

| Genty | 740 rub. / 490 rubles. | |

| Painted | 1190 rub. / 940 rubles. | |

| Buy | ||

| ProfileUYS. |  |

|

| 21*145(135)*6000 21*145(135)*4800 | Without painting | 540 rub. / 290 rubles. |

| Genty | 740 rub. / 490 rubles. | |

| Painted | 1190 rub. / 940 rubles. | |

| Buy | ||

| ProfileUYL. |  |

|

| 21*145(135)*6000 21*145(135)*4800 | Without painting | 540 rub. / 290 rubles. |

| Genty | 740 rub. / 490 rubles. | |

| Painted | 1190 rub. / 940 rubles. | |

| Buy | ||

| ProfileUYW (Spool + Planken) |  |

|

| 21*145(135)*6000 21*145(135)*4800 | Without painting | 540 rub. / 290 rubles. |

| Genty | 740 rub. / 490 rubles. | |

| Painted | 1190 rub. / 940 rubles. | |

| Buy | ||

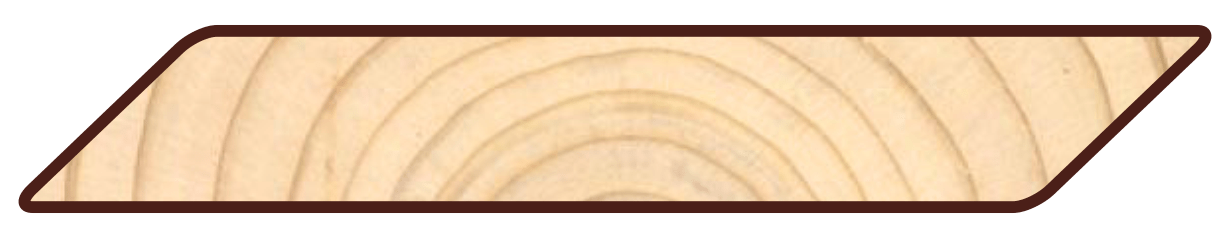

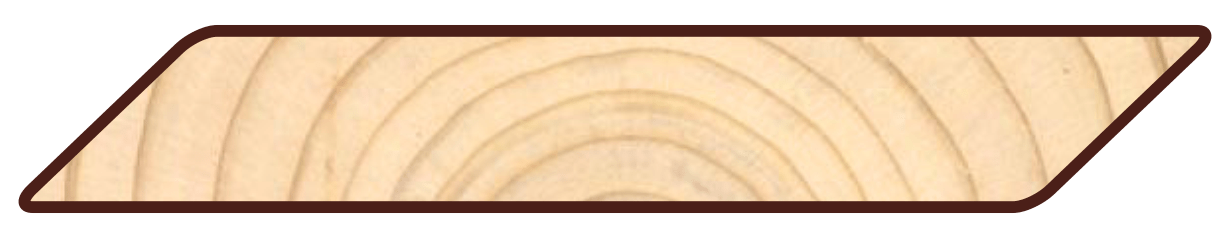

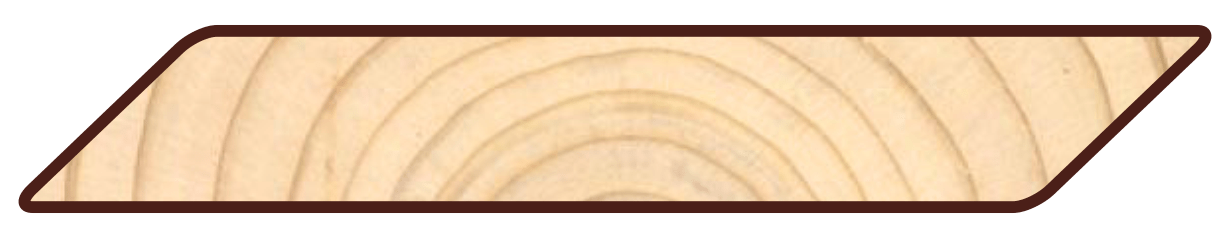

| ProfileKosy Planken. |  |

|

| 21*145(130)*6000 21*145(130)*4800 | Without painting | 540 rub. / 290 rubles. |

| Genty | 740 rub. / 490 rubles. | |

| Painted | 1190 rub. / 940 rubles. | |

| Buy | ||

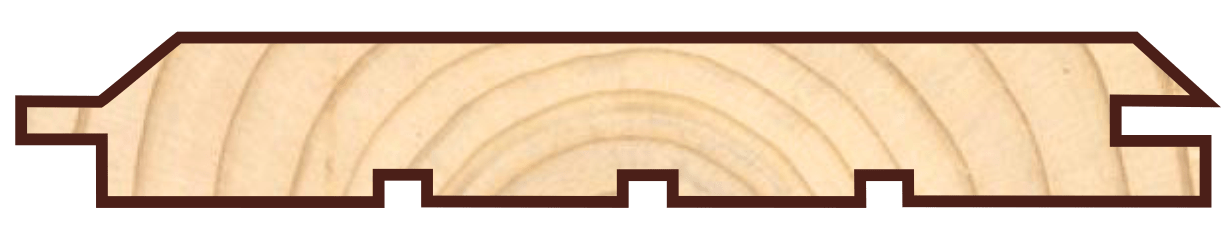

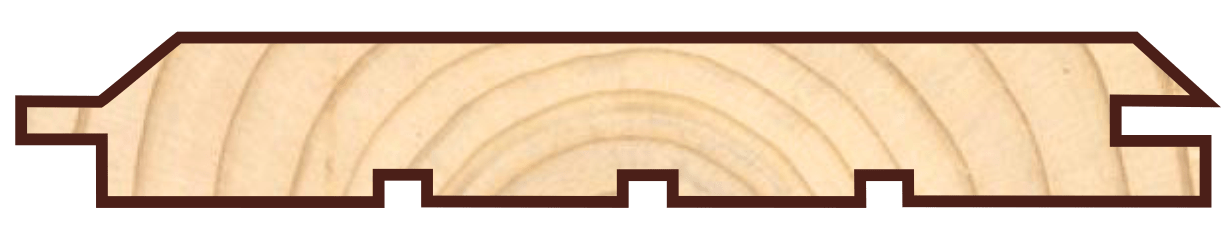

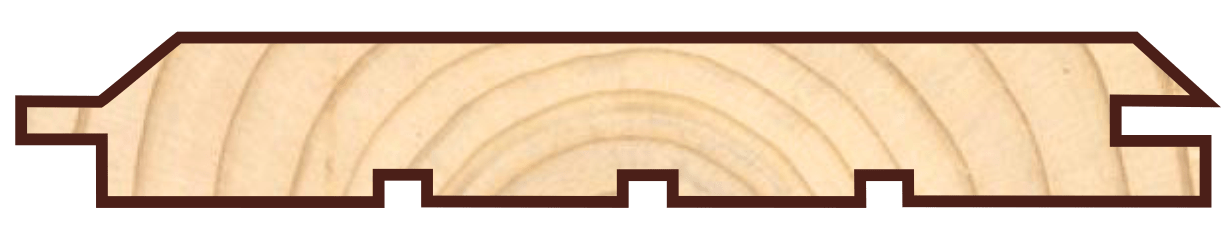

| ProfileUTF (brusade imitation) |  |

|

| 21*145(135)*6000 21*145(135)*4800 | Without painting | 540 rub. / 290 rubles. |

| Genty | 740 rub. / 490 rubles. | |

| Painted | 1190 rub. / 940 rubles. | |

| Buy | ||

| ProfileKm4r (straight plaque) |  |

|

| 21*95/120/145*6000 21*95/120/145*4800 | Without painting | 540 rub. / 290 rubles. |

| Genty | 740 rub. / 490 rubles. | |

| Painted | 1190 rub. / 940 rubles. | |

| Buy | ||

| ProfileKm2r. |  |

|

| 21*95/120/145*6000 21*95/120/145*4800 | Without painting | 540 rub. / 290 rubles. |

| Genty | 740 rub. / 490 rubles. | |

| Painted | 1190 rub. / 940 rubles. | |

| Buy | ||

| ProfileKM |  |

|

| 21*95/120/145*6000 21*95/120/145*4800 | Without painting | 540 rub. / 290 rubles. |

| Genty | 740 rub. / 490 rubles. | |

| Painted | 1190 rub. / 940 rubles. | |

| Buy | ||

This section of the price list contains products with an ideally smooth painted surface of the board, the so-called "furniture quality". Previously, such a board is definitely polished on the calibration and grinding machine, and then paint. Since in this case there are two additional operations: primary grinding and interlayer grinding, the cost of this finishing board above, rather than Scandinavian.

- Packaging through foam film and loading

For tints, sleeps (ends) boards will be provided by LKM (free)

| Dimensions, mm. | Painting | Price per m2. |

| AV / C | ||

| ProfileUYV. | ||

| 21*145(135)*6000 21*145(135)*4800 | Without painting | 540 rub. / 290 rubles. |

| Painted | 1440 rub. / 1190 rubles. | |

| Buy | ||

| ProfileUYS. |  |

|

| 21*145(135)*6000 21*145(135)*4800 | Without painting | 540 rub. / 290 rubles. |

| Painted | 1440 rub. / 1190 rubles. | |

| Buy | ||

| ProfileUYW (Spool + Planken) |  |

|

| 21*145(135)*6000 21*145(135)*4800 | Without painting | 540 rub. / 290 rubles. |

| Painted | 1440 rub. / 1190 rubles. | |

| Buy | ||

| ProfileKosy Planken. |  |

|

| 21*145(130)*6000 21*145(130)*4800 | Without painting | 540 rub. / 290 rubles. |

| Painted | 1440 rub. / 1190 rubles. | |

| Buy | ||

| ProfileUTF (brusade imitation) |  |

|

| 21*145(135)*6000 21*145(135)*4800 | Without painting | 540 rub. / 290 rubles. |

| Painted | 1440 rub. / 1190 rubles. | |

| 28*193(185)*6000 | Painted | 1640 rub. |

| Buy | ||

| ProfileKm4r (straight plaque) |  |

|

| 21*95/120/145*6000 21*95/120/145*4800 | Without painting | 540 rub. / 290 rubles. |

| Painted | 1440 rub. / 1190 rubles. | |

| Buy | ||

| ProfileKm2r. |  |

|

| 21*95/120/145*6000 21*95/120/145*4800 | Without painting | 540 rub. / 290 rubles. |

| Painted | 1440 rub. / 1190 rubles. | |

| Buy | ||

| ProfileKM |  |

|

| 21*95/120/145*6000 21*95/120/145*4800 | Without painting | 540 rub. / 290 rubles. |

| Painted | 1440 rub. / 1190 rubles. | |

| Buy | ||

The technological process of painting planing products consists of the following operations: - grinding or brash (appropriate machine)

- Priming Aqua Primer 2907 / Teknol 3881 (spraying)

- Application of the 1st layer of varnish Aquatop 2600 (ch / Mat) / Paint Nordica Eco 3330 (spraying)

- Intermediate grinding (machine, grain R 220)

- Application of the 2nd layer of varnish Aquatop 2600 (ch / Mat) / Paint Nordic Eco 3330 (spraying)

- Packaging through foam film and loading

For tints, sleeps (ends) boards will be provided by LKM (free)

| Dimensions, mm. | Painting | Variety | Price per m2. |

| ProfileKosy Planken. |  |

||

| 20*140(125)*4000 20*115(100)*4000 | Painted | AU | 1890 rub. |

| A-Prima | 2190 rubles. | ||

| Extra | 2590 rubles. | ||

| Buy | |||

| ProfileDirect Plakenken |  |

||

| 20*140*4000 20*120*4000 20*90*4000 | Painted | AU | 1890 rub. |

| A-Prima | 2190 rubles. | ||

| Extra | 2590 rubles. | ||

| Buy | |||

| ProfileImitation Bruus |  |

||

| 20*140(135)*4000 | Painted | AU | 1890 rub. |

| A-Prima | 2190 rubles. | ||

| Extra | 2590 rubles. | ||

| Buy | |||

| ProfileTerraced deck board |  |

||

| 28*140*4000 | Painted | AU | 2040 rub. |

| A-Prima | 2540 rub. | ||

| Extra | 2840 rub. | ||

| Buy | |||

| ProfileTerminal Platform Welvet |  |

||

| 28*140*4000 | Painted | AU | 2040 rub. |

| A-Prima | 2540 rub. | ||

| Extra | 2840 rub. | ||

| Buy | |||

Sales leaders in this section are the lining Clean and imitation of the bar. Colding calm is often cutting the ceilings, and the imitation of the timber is used for interroom frameless walls In the houses from the bar.

In order to stand out and implement a non-standard designer idea, we suggest you to consider other interesting profiles. For example, slanting plaquen or pinned analog UYW, as well as a UYS profile for vertical finish.

The technological process of painting planing products consists of the following operations: - grinding or brash (appropriate machine)- Priming Aqua primer 2900 (spraying)

- Application of the 1st Layer of Wax / Lacquer / Paints Temnaks 1160 / Aqua 2550 (spraying)

- Intermediate grinding (machine, grain R 220)

- Application of the 2nd Wax / Lacquer Layer / Paints Temnaks 1160 / Aqua 2550 (Spraying)

- Packaging through foam film and loading

For tints, sleeps (ends) boards will be provided by LKM (free)

In the interiors, the use of aged board is very popular, which is obtained by layer-by-layer application of the LKM on the brashboard. Please note that the cost is simply ground board and we have the same.

| Dimensions, mm. | Painting | Variety | Price per m2. |

| ProfileWalking Shtail |  |

||

| Pine-fir | |||

| 15*135(130)*6000 | Painted | AU | 1290 rubles. |

| 21*145(135)*6000 | Painted | AU | 1390 rub. |

| Larch | |||

| 14*138(132)*4000 | Painted | AU | 1640 rub. |

| A-Prima | 1940 rub. | ||

| Extra | 2240 rub. | ||

| Buy | |||

| ProfileImitation Bruus |  |

||

| Pine-fir | |||

| 17*145(135)*6000 | Painted | AU | 1290 rubles. |

| 21*145(135)*6000 | Painted | AU | 1390 rub. |

| 28*193(185)*6000 | Painted | AU | 1590 rub. |

| Larch | |||

| 20*140(135)*4000 | Painted | AU | 1840 rub. |

| A-Prima | 2140 rub. | ||

| Extra | 2540 rub. | ||

Content:

The sheathing of walls, ceilings and other elements of the inner residential space of a country house or an apartment with finishing materials from a natural tree is, firstly, the ability to give the space of the house special decorativeness and, secondly, to protect them from mechanical impacts and excessive humidity.

With the internal decoration of the walls of the house between the crate and the finishing surface, as a rule, a multilayer structure, which has protective, sound and heat-insulating qualities is paved.

The invaluable advantages of natural wood, as a facing material for outdoor and interior decoration of the house, make it possible to consider this material almost indispensable in many ways. In this article we will consider and compare the options for finishing the interior, in detailing on their advantages and disadvantages.

Despite the external associations with the above-described clap, is a practically new European "invention". From the lining, this finishing material is distinguished by a number of tangible advantages. The first is a compliance with tough European (first of all - German) quality standards, which in itself is a convincing argument in its favor.

The quality of the Euro woman and the level of environmental processes is monitored by almost all stages of its production, and even earlier - starting from the selection of wood. As a raw material for the production of Euroovallee is used mainly wood coniferous rocks Trees, often grown purposefully. But, even with such a hard monitoring of Eurovantia, it is divided into classes - the first, second and third.

They are distinguished by eurvagon from standard lining and extremely accurate geometric dimensions of surfaces, which allows assembly with minimal tolerances. As a result, both the finished surface and its individual fragments are distinguished by very high decorativeness. In addition to the noted dignity, the Eurovantia is additionally equipped with a moisture and ventilation system in the form of a furrow specifically provided for this purpose. Such a solution allows to provide increased durability both the wall tag and the main wall of the house. Conservation is also eliminated, due to the swelling of woody fibers in high humidity.

The perfectly smooth and pleasant to the touch surface of the Euro woman in production is covered by special compositions, which makes it possible not to carry out its additional processing of the LKM, as in the case of a regular clapboard. In this case, the texture of the tree, unique for each breed, remains in the center of attention of the "viewer".

Today it becomes the subject of special pride of owners of elite houses, cottages, restaurants. Due to its unique decorative properties and composition, high-quality Eurovantia creates a healthy microclimate in the house, comfort and special comfort.

|

|

|

When the walls and the ceiling are ready, decorated and breathe freshness, cleanliness, having a pleasant pastime for a cup of fragrant herbal tea, as it turns out, to relax early - you should think about the flooring for the floor! Of course, B. the best traditions Lovers of a healthy lifestyle, flooring should also be natural, i.e. - wooden.

This is a pinched manner, manufactured on modern high-precision woodworking equipment from selected boards such as tangential and radial cuts. The humidity of the finished quality product should not exceed 10%.

Treating the category of luxury and most expensive natural materials for the interior of the house, the massive floor board has many advantages, the main of which are a healthy microclimate in the house, heat, comfort when walking, high decorativeness and durability. The last moment deserves special attention, and the best proof of this is European castles, who have previously over 500 years old and are still posing tourists with "authentic" floors from the massive floorboard.

Considering that modern technologies Wood dryers and use in the production of massive floor board of valuable wood wood allow today to receive a product with unique performance. Such a massive board "breathes", i.e., it is sensitive to changes in humidity in the premises, actively absorbing its surplus and "optimizing" thereby the microclimate indoors. To the long list of advantages of the massive floor board should be added low thermal conductivity, high soundproofing qualities. A massive board on the principle of spike is connected, which allows you to produce high-quality installation quickly and gently.

Modern finishing coating The massive floor board is manufactured in accordance with the requirements of Russian and European standards. Over the entire length of the board, the "chamfer" is allowed, which gives the finished coverage of originality and special expressiveness.

One of the main advantages of a massive floorboard is the possibility of repeated updates. Since the thickness of the working layer lies within 12 - 45mm, then the board is allowed to grind, respectively, at least 15 times. Very popular in the manufacture of wooden floor board larch Siberian and Angarsk pine. In order for the massive board to serve you by faith and true for many years, the requirements for protection against impact, moisture, heat and sound insulation should be taken into account. Largely contributes to this right choice Substrates. An excellent option is a Kraiburg substrate, which is able to significantly improve the wear resistance of the laid massive board, smooth the micronetheriness of the base, and therefore significantly improve and extend the life of the coating.

Best of all the floor of a massive board looks in the premises of a large area, especially where sufficient natural lighting is provided. Declarated by manufacturers service life - not less than 100 years - for our age enough!

Wooden block - House in interior decoration

Amazing decorative properties, acceptable price and ecological neutrality Block-house causes its popularity as practical and convenient in the care of the finishing material. both for external and interior decoration. As a material for the production of a block of house, various types of wood can be used, but the most common remains, of course, the pine and larch Siberian. High degree of drying wood Block - Haws guarantees its durability and resistance to cracking, warping and other deformations. Very decoratively looks a block - a house of cedar, birch or linden.

Mounted in your home block house deprived of disadvantages characteristic of a rounded log cabin, in particular, spoiling decorative appearance longitudinal cracks. Impregnation with antiseptics and antipirens allows you to achieve improved performance.

Walls made of brick, foam concrete, concrete and other low-destructive surfaces after finishing the block - House look just amazing. Low cost Block-house allows you to use this unique finishing material for both finishing of private houses and cottages and in the interior of the cafe, hotels are decorated in country style. Panels Block - Haws used for interior decoration, thickness and width (20mm x 80 ... 90mm, respectively) less than the panels used in the exterior decoration. In the corners, individual panels are joined by special corners, which allows you to create a sense of whole facade.

The entire clap passes the same production cycle, and only at the final stage of sorting, it takes place on the varieties of external signs.

- grade "A" allows the presence of bitch light color;

- the "B" variety allows the presence of "non-living" bitch of dark color.

At the same time, the dropouts and visible defects are not allowed.

The high concentration of the resin and the hardness of larch wood is very complicated by its processing, but in return gives the finished product with unique operational and environmental characteristics. The atmosphere of the house whose walls are covered with finishing material from larch, impregnated with phytoncides - substances that are beneficial affecting the lungs, cardiovascular and vascular and nervous system Hosts and guests at home. Block - House from larch is durable and durable, the quality of the best block - Haws class "Extra" complies with European standards.

Home finish imitation timber

- a handguard, a variety of lining, actively used today for internal and exterior decoration houses, saunas, baths, apartments. Simulation of the bar is not only a spectacular finishing material that allows you to create a feeling of comfort and comfort in the room, but it is the material that allows minimal means to completely transform the space at home. It will not be necessary for such cardinal changes and global restructuring of the building, the transfer of walls and partitions.

Wood selection for interior decoration

The tree of different breeds is a constant favorite in the exclusive design of the interior, and is perfect for use when creating both modern and traditional styles. Oaks, ash, nut and maple are appreciated among hardwood, among the coniferous excellent selection will be pine, spruce, cedar and red tree. The first thing that will be required, regardless of which finishing material you will use is to determine in favor of deciduous or coniferous rocks. The question is not so simple, as it seems at first glance, and for a qualified response to it, you will still be better to contact your architect or contractor.

- Availability of a material;

- How interested in the breed of wood is ready for the processing you need;

- How time consuming will be care for such a finishing coating;

- As far as the selected option corresponds to the operating conditions of the setting requirements for wear resistance.

Approximate prices for internal finishing materials

Some types of work:

- Mounting lining - 300 rubles. / sq.m.

- Installation of block house - 400 rubles. / sq.m.

- Installation of timing of timber - 400 rubles. / sq.m.

The estimated cost of finishing a turnkey tree

Room size 15KV. m. When height ceilings 2.5m - 1630 rubles / sq.m. The finishing rate includes:

- ceiling cover and wall clapboard;

- installation of outdoor I. ceiling plinth;

- covering with lining slopes windows and doors;

- installation of lag and flooring flooring.

The inner finish of the house with natural wood materials is an excellent investment in a healthy lifestyle, the opportunity to surround themselves with elements of the style created and honed by the most advanced designer from all existing - the most nature.

Facing walls by boards, although it does not apply to innovative finishing methods, previously applied quite rarely. Modern designers Increasingly use this technique to create interiors in ecostel and in Provence.

Advantages of using boards

The main advantages of this material in the walls of the walls include:

- high environmental friendliness;

- economy (depending on what kind of type of material you buy);

- significant heat and sound insulation properties;

- strength and resistance to mechanical damage;

- durability;

- the possibility of laying thermal insulation material;

- fast repairs (surface tapping, replacing individual damaged elements).

Selection of material

The lining of the walls is produced by almost any type of material, depending on the wishes of the owners of the house. It can be parquet, deck, facade and even the most ordinary boards, including a horn. It does not matter whether they have a docking puzzle compound or will be in a natural, not polished form, the modern interior fashion involves the possibility of any, even the most courageous solutions.

However, there are restrictions - the material must necessarily be carefully succeeded, the humidity of the tree is allowed from 2 to 15%, not more. Otherwise, it will get out, the boards can crack, there is a risk of infection with mold.

Main stages of mountage

Step-by-step wall cladding board consists of several main stages:

- Preparation of the surface.

- Mounting frame (if required).

- Fastening boards.

- Padding.

- Opening with varnish, mourn or painting.

Surface preparation

Preparation of the surface of an important stage of finishing works. It lies in:

- cleaning the walls from strongly sprinkling elements of plaster;

- sealing cracks, cracks;

- processing with special antiseptic solutions;

- thorough drying of the working plane;

- fastening a vapor barrier film if the insulation is configured.

Frame and frameless ways to fastening boards

Boards can be mounted on the frame or directly to the walls. The frameless cladding method implies a smooth surface, with minor level drops. The benefits include the ease and speed of installation.

The skeleton method is the preliminary installation of the crate - metal from Mon and PS profiles or wooden, which, in principle, it comes much more economical. This method allows you to perform insulation of walls, but if the boards are planted with gaps, insulation should not be applied based on mineral Wat.

Before installing the crate, you should calculate the dew point and its possible offset, taking into account the presence of the insulation and the main external material. If it is shifted to the inner surface of the wall, the design should be revised to avoid the appearance of mold and fungus or conduct a thorough external insulation.

Wooden doom. FEATURES OF MONTAGE

To install a wooden crate, you should prepare the dried bars of 30 × 30 mm or 50 × 25 mm previously treated with an antiseptic agent. Before mounting, they need to hold in a room at least 5-6 days on a flat surface for acclimatization.

You will need the following tools:

- Carrying (if an electrode is used).

- Electrolovka or tree hacksaw.

- Electrode or screwdriver.

- Chisel.

- Pencil or chalk.

- Dowels 10 × 130 mm, if the base surface is concrete or brick.

- Self-tapping screws (if the base is wooden).

- Level or level.

- Lining lumps.

The lamp is fastened horizontally, in case the boards are mounted vertically and vice versa.

Rack Step - 50 cm, selfless or dowel - 45-50 cm, indenting the ceiling / floor - 10 cm.

If the length of the sizing bars were small, they can be increasing, if on the contrary, are large, after measurements and marks, cut off with an excess electrolovka or hacksaw.

Using the level, capture the differences and install the lining bars of suitable sizes to align the frame.

It is important at this stage not to forget to bring wiring. It is better to do this in the afternoon if it is connected to the power grid, as it is necessary to de-energize it, for security purposes. It is necessary to closely ensure that each bare wire is carefully drawn to the end of work.

Under hidden wiringIt is necessary using the chisel to cut holes in the suitable size of a suitable value if they somehow intersect that it happens more often when the boards are vertical installation.

After installing the frame, you must once again make sure that it is fixed exactly in terms of the level, fix the insulation, if it is used and can be attached to the screwing of the boards.

Installation of board

It is important to pre-inspect the material for the presence of the treasures and immediately, on initial stage Remove the planks on which they are available.

Before mounting, boards must be allowed to fly off indoors at least 5 days.

After that, to treat the means against beetles, for example, a "barrier", and the flame.

Before pruning the elements of the appropriate length, all measurements are made very carefully, the skirts that will be attached above doorways, It is necessary to leave with a light point and cut flush with each other after screwing.

For installation you will need:

- Self-tapping screws. You can use nails, but in this case, the repair of the coating will be more problematic.

- Carrying (again, if drill is used, as well as for smooth trimming of boards with an electric bison above door openings).

- Electrode or screwdriver.

- Crowns on wood, if it means the need for round holes for any pipes.

- Drawing on wood or electrolybiz.

The method of fastening boards depends on the presence of either the absence of puzzle compounds and can be both secret and open.

Fastening "Schip-Paz"

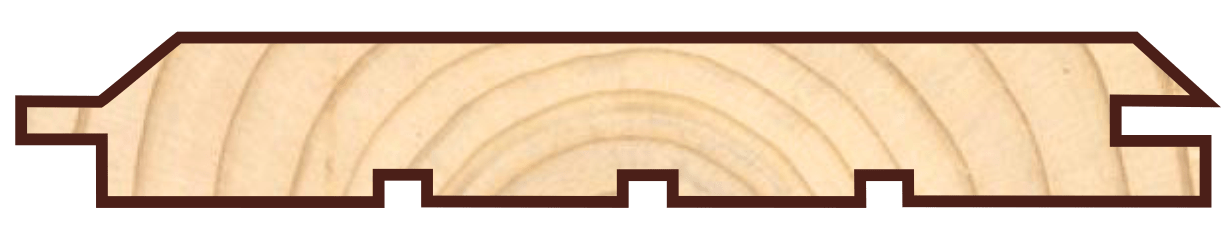

Schip-groove is a special kind of hidden fastening, which implies a dense connection of elements with a minimal docking seam. On one end of the material is located along the entire length of the longitudinal vertical excavation - the groove, and on the second - the comb - spike.

The starting and finishing board usually has only a groove, but if they are not available, the scallop can be trimmed with an electroll bison, and then the surface is neatly stabbed.

Stages of wall cladding boards

Stying begins with the opposite wall from the entrance to the room. The starting board is installed and it is screwed into a screwdriver through the groove to the crate or directly to the wall, with the help of self-tapping screws, whose caps are slightly taken, but do not ride until it stops. The screwdrive movement is regulated by the step of cage rail, in the case of frameless fasteners, it is 45-50 cm.

The next board is inserted by the row in the groove of the previous one and is also fixed through the groove.

Open fastening

Used in the absence of puzzle compounds. When using this method, nails or self-tapping screws are fixed directly to the outer surface of the material. However, it should be attentive if the evenness of the screws of the screws is important for you.

The step of installing the screws is adjustable in such a way that each fastening element He entered the middle of the rabral crate or, in its absence, every 45-50 cm.

Boards above door openings, krepim with letters in length, at the end of the installation, they are trimmed along a flat line marked. The same applies to windows.

Completion of wall decoration boards

The end point of laying boards is cleaning them from the construction dust, grinding in places of open fastening elements, priming the surface, opening with varnish, brash or painting with water-level paints.

It should be noted that the cladding of boards loses its meaning, if after applying the decorative layer, natural wood texture disappears.

Upon completion of the installation, all subsequent finishing work In the room, it is recommended to be carried out no earlier than the complete drying of the boards.

Content:

The sheathing of walls, ceilings and other elements of the inner residential space of a country house or an apartment with finishing materials from a natural tree is, firstly, the ability to give the space of the house special decorativeness and, secondly, to protect them from mechanical impacts and excessive humidity.

With the internal decoration of the walls of the house between the crate and the finishing surface, as a rule, a multilayer structure, which has protective, sound and heat-insulating qualities is paved.

The invaluable advantages of natural wood, as a facing material for outdoor and interior decoration of the house, make it possible to consider this material almost indispensable in many ways. In this article we will consider and compare the options for finishing the interior, in detailing on their advantages and disadvantages.

Despite the external associations with the above-described clap, is a practically new European "invention". From the lining, this finishing material is distinguished by a number of tangible advantages. The first is a compliance with tough European (first of all - German) quality standards, which in itself is a convincing argument in its favor.

The quality of the Euro woman and the level of environmental processes is monitored by almost all stages of its production, and even earlier - starting from the selection of wood. As a raw material for the production of Euroovali is used mainly wood of coniferous trees, often grown purposefully. But, even with such a hard monitoring of Eurovantia, it is divided into classes - the first, second and third.

They are distinguished by eurvagon from standard lining and extremely accurate geometric dimensions of surfaces, which allows assembly with minimal tolerances. As a result, both the finished surface and its individual fragments are distinguished by very high decorativeness. In addition to the noted dignity, the Eurovantia is additionally equipped with a moisture and ventilation system in the form of a furrow specifically provided for this purpose. Such a solution allows to provide increased durability both the wall tag and the main wall of the house. Conservation is also eliminated, due to the swelling of woody fibers in high humidity.

The perfectly smooth and pleasant to the touch surface of the Euro woman in production is covered by special compositions, which makes it possible not to carry out its additional processing of the LKM, as in the case of a regular clapboard. In this case, the texture of the tree, unique for each breed, remains in the center of attention of the "viewer".

Today it becomes the subject of special pride of owners of elite houses, cottages, restaurants. Due to its unique decorative properties and composition, high-quality Eurovantia creates a healthy microclimate in the house, comfort and special comfort.

|

|

|

When the walls and the ceiling are ready, decorated and breathe freshness, cleanliness, having a pleasant pastime for a cup of fragrant herbal tea, as it turns out, to relax early - you should think about the flooring for the floor! Of course, in the best traditions of lovers of a healthy lifestyle, the flooring should also be natural, i.e. - wooden.

This is a pinched manner, manufactured on modern high-precision woodworking equipment from selected boards such as tangential and radial cuts. The humidity of the finished quality product should not exceed 10%.

Treating the category of luxury and most expensive natural materials for the interior of the house, the massive floor board has many advantages, the main of which are a healthy microclimate in the house, heat, comfort when walking, high decorativeness and durability. The last moment deserves special attention, and the best proof of this is European castles, who have previously over 500 years old and are still posing tourists with "authentic" floors from the massive floorboard.

Considering that modern wood drying technologies and the use of a massive flooring board of valuable wood wood allow today to receive a product with unique performance. Such a massive board "breathes", i.e., it is sensitive to changes in humidity in the premises, actively absorbing its surplus and "optimizing" thereby the microclimate indoors. To the long list of advantages of the massive floor board should be added low thermal conductivity, high soundproofing qualities. A massive board on the principle of spike is connected, which allows you to produce high-quality installation quickly and gently.

Modern finishing coating The massive floor board is manufactured in accordance with the requirements of Russian and European standards. Over the entire length of the board, the "chamfer" is allowed, which gives the finished coverage of originality and special expressiveness.

One of the main advantages of a massive floorboard is the possibility of repeated updates. Since the thickness of the working layer lies within 12 - 45mm, then the board is allowed to grind, respectively, at least 15 times. Very popular in the manufacture of wooden floor board larch Siberian and Angarsk pine. In order for the massive board to serve you by faith and true for many years, the requirements for protection against impact, moisture, heat and sound insulation should be taken into account. In many ways, it will contribute to this correct substrate. An excellent option is a Kraiburg substrate, which is able to significantly improve the wear resistance of the laid massive board, smooth the micronetheriness of the base, and therefore significantly improve and extend the life of the coating.

Best of all the floor of a massive board looks in the premises of a large area, especially where sufficient natural lighting is provided. Declarated by manufacturers service life - not less than 100 years - for our age enough!

Wooden block - House in interior decoration

Amazing decorative properties, acceptable price and ecological neutrality Block-house causes its popularity as practical and convenient in the care of the finishing material. both for external and interior decoration. As a material for the production of a block of house, various types of wood can be used, but the most common remains, of course, the pine and larch Siberian. High degree of drying wood Block - Haws guarantees its durability and resistance to cracking, warping and other deformations. Very decoratively looks a block - a house of cedar, birch or linden.

Mounted in your home block house Decide the disadvantages characteristic of a rounded log, in particular, spoiling a decorative appearance of longitudinal cracks. Impregnation with antiseptics and antipirens allows you to achieve improved performance.

Walls made of brick, foam concrete, concrete and other low-destructive surfaces after finishing the block - House look just amazing. Low cost Block-house allows you to use this unique finishing material for both finishing of private houses and cottages and in the interior of the cafe, hotels are decorated in country style. Panels Block - Haws used for interior decoration, thickness and width (20mm x 80 ... 90mm, respectively) less than the panels used in the exterior decoration. In the corners, individual panels are joined by special corners, which allows you to create a sense of whole facade.

The entire clap passes the same production cycle, and only at the final stage of sorting, it takes place on the varieties of external signs.

- the variety "A" allows the presence of bitch of light color;

- the "B" variety allows the presence of "non-living" bitch of dark color.

At the same time, the dropouts and visible defects are not allowed.

The high concentration of the resin and the hardness of larch wood is very complicated by its processing, but in return gives the finished product with unique operational and environmental characteristics. The atmosphere of the house, the walls of which are covered with finishing material from larch, impregnated with phytoncides - substances that are beneficial affecting the lungs, cardiovascular and the nervous system of hosts and guests at home. Block - House from larch is durable and durable, the quality of the best block - Haws class "Extra" complies with European standards.

Home finish imitation timber

- Makeup, type of lining, actively used today for the inner and exterior decoration of houses, saunas, baths, apartments. Simulation of the bar is not only a spectacular finishing material that allows you to create a feeling of comfort and comfort in the room, but it is the material that allows minimal means to completely transform the space at home. It will not be necessary for such cardinal changes and global restructuring of the building, the transfer of walls and partitions.

Wood selection for interior decoration

The tree of different breeds is a constant favorite in the exclusive design of the interior, and is perfect for use when creating both modern and traditional styles. Oaks, ash, nut and maple are appreciated among hardwood, among the coniferous excellent selection will be pine, spruce, cedar and red tree. The first thing that will be required, regardless of which finishing material you will use is to determine in favor of deciduous or coniferous rocks. The question is not so simple, as it seems at first glance, and for a qualified response to it, you will still be better to contact your architect or contractor.

- Availability of a material;

- How interested in the breed of wood is ready for the processing you need;

- How time consuming will be care for such a finishing coating;

- As far as the selected option corresponds to the operating conditions of the setting requirements for wear resistance.

Approximate prices for internal finishing materials

Some types of work:

- Mounting lining - 300 rubles. / sq.m.

- Installation of block house - 400 rubles. / sq.m.

- Installation of timing of timber - 400 rubles. / sq.m.

The estimated cost of finishing a turnkey tree

Room size 15KV. m. When height ceilings 2.5m - 1630 rubles / sq.m. The finishing rate includes:

- ceiling cover and wall clapboard;

- installation of outdoor and ceiling plinth;

- covering with lining slopes windows and doors;

- installation of lag and flooring flooring.

The inner finish of the house with natural wood materials is an excellent investment in a healthy lifestyle, the opportunity to surround themselves with elements of the style created and honed by the most advanced designer from all existing - the most nature.

Today, the decoration of the walls of the board is very popular. It helps to create different interiorsBut they are united by one - love for nature, to all natural. The article will talk about what types of finishing board exist, the choice of some styles can justify the use of wood.

What interior styles allow wall decoration board

Tree - natural material, safe and beautiful, very decorative and surprisingly warm. It can be used to implement any style, it makes it universal. Such a finish is appropriate and in the loft, and in techno, and in minimalism. If the walls are selected for wall decoration in the house, the interior is noticeably transformed. It is perfectly combined with other finishing materials. And this is not the only advantage of choice.

Exists a large number of breed. Each type of wood has its own drawing, its color. This allows you to select the material under the appearance of other elements of the interior decor. Larch - Very durable material, withstands high loads, is well processed, amenable to staining, a veil, is ideal for plating cold rooms, such as a balcony or loggia.

Pine is distinguished by moisture resistance, so it is most often used to decorate walls in the bathroom. Oak - luxury material, with a very beautiful wood pattern. If using it to place the walls of the living room, bedroom or cabinet, and grandchildren and great-grandchildren will admire them.

Lipa is a soft tree, easily processed. Designers choose it when you need to make semicircular or curved walls. Walnut, cherry, mahogany - elite breeds. They are the basis for creating classic interiors.

There are styles, the implementation of which is impossible without the use of wood. If provence is selected for the decoration of residential space, wood must be present in the floor finish, walls, and even the ceiling. The less it is processed, the better. Deliberately rough texture is ideal for country.

Any ethnic direction is best combined with wood. And all because the concepts of national directions were born when it was the main finishing material, when there was no plastic, and the metal was very expensive.

Nowadays, a popular stylization under ancient is considered. To create interiors, designers specially constitute surfaces. Best of all this processing is a tree. If you correctly choose the basis, there will be cracks, chips and potholes on it. Color treatment will emphasize their presence and expose the "age" of the material. The wall, trimmed by him, will greatly look in the vintage interior, in the room decorated in the style of eclectics.

Advantages of using decorative boards for registration of sheer surfaces

The lining of the walls of the board improves the soundproofing of the apartment. If the insulation, heat loss in the house in the winter period in the winter period is noticeably reduced inside the root. This will allow you to start saving on heating.

The coating does not require complex care, the slats are additionally covered with protective compositions. The latter prolong the service life and help for a long time to forget about the overhaul.

The tree can be repainted, such an operation allows you to drastically change the atmosphere of space and completely update it without capital investments.

Manufacturers offer a wide range of sawn timber, suitable for interior wall decoration. There are among them affordable options and expensive samples, with which respectable interiors are created. The use of each variety allows you to form your decorative effect.

Types of finishing board

Designers are actively used for the design of the walls five types of finishing board. They have a lot in common, but there are also their differences. They play a decisive role in the formation of aesthetic effect.

This decorative wall decoration is used most often. And all because the material is most affordable. This fact does not deprive it of all the advantages of wood finish.

Lining - thin wooden lamellas that are manufactured in the factory conditions. They are thoroughly grinding with an outer face, a small chamfer is formed on the sides, which makes the relief of the finished finish texture.

Special grooves are created on the ends, they greatly simplify the procedure for mounting the lining. It is installed on a wooden crate. Under it you can hide engineering communications and wiring. If the emptiness formed between the wall and finished finish is filled with mineral wool slabs, heat and sound insulation of the room will improve. The decorative characteristics of the lining depends on which wood was used for its manufacture.

Imitation Bruus

Until recently, such material was used to finish the facade, today they are actively shedding the house from the inside. This technique helps to completely change the living space, make it chamber, but cozy. If all the inner surfaces are crushed, the feeling of presence in the present will be created brusade house. Manufacturers produce two varieties of falsebrus:

1. One - a pure untreated finishing board for walls, not covered with protective compositions.

2. The second is a toned finish, impregnated with antiseptics and a special color.

If there is a desire to save, it is better to choose the first version of the manufacture for finishing the walls. Then it is independently covered by the compositions that protect wood from fungus and mold. Processing with protective varnish will extend the service life of the finish. Toned Fishbrus is more suitable for the facade. But it can also be used for interior decoration, if its color perfectly fits into the overall interior stylist.

From the lining imitation of the bar differs in the way that the width of the lamella is much larger, more and the thickness of the board. The chamfer on the edges of the Falchbruss is absent. Otherwise, the design of both boards is similar: there is a spike-groove system on the ends. Similar to materials and installation method.

Block house

At block house, the outer face has a semicircular cross section. If you put such decorative boards on the wall, the feeling of the fact that it is collected from natural wooden sruba. In fact, the block house is one of the four sides of the log barrel, from which the core was taken out, square shape. The material has the most natural appearance.

For making manufacturers prefer to use pine or spruce. They are easier to handle, and very interesting looks in different interior functionality. If such a material is chosen to create an internal trim, specialists Council tools Buy chalkboard for walls of the tree category "A". They have a perfectly smooth surface that looks particularly expressive in the design of residential rooms.

It is used as a falsebrus alternative. Externally, it looks very similar to him, the differences are that the plaquena does not have a spike-groove compound. This board for plating walls inside the house is also perfect: the lamellas have a long oblong shape, in the assembled form they look like neatly laid rails. Usually, with the help of them, only one sheer surface is sized. In this way, designers create accent walls, on the background of which one element of the decor will then be revealed.

At the edges of the plaquena there are pointed or rounded chamdes. They are used when assembling ensure that there are smooth gaps. Such an element allows you to form a clear rhythm. Why the appearance of the finished finish only wins. Gaps between boards - necessary constructive element. If the lamellas absorb a large amount of moisture, they expand. When the air indoors are overlooking, they are sinking. The presence of a technical clearance compensates for oscillations.

Parquet board

Today and it is actively used by designers for wall decoration. Its lamellas also have an elongated rectangular shape, but they are much shorter than the Fishbruss lamellas or block house, so after the assembly is created the effect of the deck floor. When such a finish decorates the walls, it immediately rushes into the eyes, caresses attention, stand out on a general background.

Usually, only one sheer surface is trimmed with such material. Different methods Styling allow you to visually change the perception of space. Vertically laid boards raise ceilings. If the lamellae is stacked diagonally, a complex geometry is formed, which expands the boundaries and creates a non-standard room.

It turns beautiful when the parquet board is stacked in one direction and on the floor, and on the wall. The room is drawn up and becomes purposefully oriented.

Video Description

The video describes how the parquet board is stacked:

Briefly about the main thing

Decorative boards have long been used by designers to decorate walls in the house. If they are squeezed by one sheer surface, it becomes the main accent, starting point for further design of the room. When all the walls are trimmed with wood, a special atmosphere of home heat appears, which man so much.

And a little more attention

Chalkboard in the interior decoration to be! And could you go to the experiment and one wall in the house or in the apartment fully alleged wood? Write in the comments if you have experience using wood in the design of the rooms than it is over, and what material liked the most.