Types of electrical cables and wires. Basic Definitions for Cable and Conductor Products

I will make a reservation immediately. This article is not intended for those who do similar issues professionally. In this case, do not waste your time! Information of this article is designed for an ordinary consumer who sooners or later has to solve the issue of filing and distributing electricity at home, in the country, etc. Of course, you can contact the specialists who will qualify for this issue. But if it is connected with significant material costs for you, take advantage of the information of this article and see that everything is not so difficult. "Do not burn the pots of pots !!!".

In order for the selection of the cable or wire is correct, you must perform several conditions.

1. It is necessary to determine the amount of insulated wires in the cable that you should be.

With a plug-in load, eating from a single-phase network (220V), this is either two wires (zero N and phase L), or three (zero, phase, and wire protective grounding).

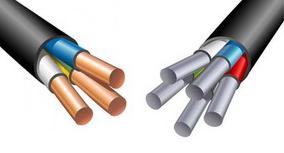

With a load feeding from a three-phase network (380V), this is either four wires (three phase A, B, C, and zero N), or five (three phase, zero and protective ground wire).

The need for a protective grounding wire is determined by the design and type of connected load. All devices with an outer metal body must be ground to prevent the electric shock. When using sockets with grounding contact, a cable with a protective ground wire is required. If you use differential safety machines when connected with the load (RCO - protective shutdown devices), the protective ground wire is simply necessary for their correct operation.

2. The cross section of the conductive livers (abbreviated by CPA - in the future I will use this abbreviation) must correspond to the power of the connected load.

If the cross section is less - the wires will overheat (the smaller the cross section of the TPZ, the greater the resistance of the wire flowing electric Toku. - Consequently, at high currents on the wire, heat will be highlighted, both on the heating element). In addition to the fact that the overheating of the wire can lead to the destruction of protective insulating covers, a short circuit and the emergence of a fire, the heating wire is the loss of energy during the transmission process !!! And these losses will pay for you exactly !!!

If the cross section of CPA will be selected excessively large - first, you will spend extra money for the purchase of a cable, and secondly, difficulties may occur when connected: all devices (terminal blocks of electrical installations, devices and mechanisms, sockets, etc.) are designed for Specific power and, accordingly, to a certain cross section of the connected wires. Not in every "hole" thick wire will be able to "flush"!

For correct choice required section CWA need to know the power of the connected load. According to the table of the maximum permissible load characteristics of the wires, we find the sequence of section. Maximum permissible load value for the selected section D.B. More power plug-in.

When connecting multiple loads to one cable for calculations, it is necessary to sum up their power.

Having understood with these two items, we figured out the digital part of the cable brand.

Each brand contains an alphabente part (characterizes the type and design of the cable) and the digital part (characterizes the amount of isolated CPA and the cross section). For example: WGP 3 * 2.5. This means a VG type cable in a flat design (letter "P"), contains three veins with a cross section of 2,5mm square meters.

Now let's deal with the "letters".

CPA wires and cables are made of copper or aluminum. Single insulated wire coming on sale will be labeled PV - for copper isolated housings, APB - for aluminum isolated housings.

CPA can be structurally single-wire (monashed) and a multi-breed-made from a smaller cross section, twisted together. Multi-War CCPs provide increased flexibility of wires and cables, which can be necessary when connecting various portable (mobile) devices and electrical appliances.

The flexibility class of the wire is denoted by the number, and the larger the digit - the higher the flexibility class of the wire (and more expensive).

PV1-2,5 - Copper insulated wire with single-filling residential cross section 2.5 mm?

PV3-1,5 - Copper insulated wire of an increased class of flexibility with a multi-breed residential cross section of 1.5 mm?

Immediately I note: it will be about a limited number of cable brands (VVG, AVVG, VG-NG, NG-LS VG, kg, NYM, PVS, SWVVP, SIP). Despite this, a small limited amount is confident that in 99% of cases in our "household" situations it will be enough.

Cables for VG and AVVG.

The cables of these brands are designed for laying in dry and wet rooms, for external and hidden stationary (CPA wires - monashed, the amount lived from two to five) wiring. Constructively, they are made in a flat (row laying lived under the shell - VDGP, AVVGP) and twisted (Round - VG, AVVG) versions. VG - CPA copper, AVVG - CPA from aluminum.

The insulation of cable wires and the outer shell is made of cable polyvinyl chloride (PVC) plasticists. PVC causes the temperature range ambient To operate cables from -40 ° C to +50 ° C, and installation and gasket without prior heating are possible at a temperature not lower than -15 ° C. Otherwise, it is possible to crack the protective covers and further flowing from here the trouble.

The minimum cable bending radius is 7.5 of its outer diameters.

The service life of the cable is 30 years.

The cable is allowed outdoors. However, the protective covers of the cable will be exposed to ultraviolet spectrum sunlight, and the cable service life will significantly reduce - the shell, and then insulation "crack up". The most resistant to the effects of the ultraviolet cable of black, as ultraviolet rays will immediately be absorbed by the surface and will not be able to penetrate inside the shell, causing the destruction of PVC polymer chains. That is why all cables for laying outdoors are produced black, and all regulatory documents strictly track this requirement !!!

When connecting the ends of cables, please note: the direct connection of copper lived with aluminum is unacceptable !!! The connection must be performed either bolted through the separation steel washer, or use special connecting pads, in which the copper and aluminum wires are clamped separately each fastening element. Otherwise, copper with aluminum form a galvanic pair and as a result are sharply oxidized at the point of contact. The resistance of the connection site increases, heating occurs, possibly melting insulation of wires, their short circuit and trouble are provided !!!

The release of cables of the VG and AVVG has long been mastered by industry. The cables were very widespread, and it should be noted that the cost of these cable brands is lower than others with a similar design.

Cables VG NG, NG-LS VG.

VG NG is cable VVG.which, as defensive covers, PVC plastic, not supporting burning. And notice - it is unsupported! Being in the area of \u200b\u200bopen fire, plastic is burning, but when the flame is terminated, it fades. Thus, the possibility of disseminating a fire during electrical wiring is prevented (if during the closure, other items should not be loaded until the voltage shut off systems are triggered).

The NG-LS UG, in addition to this, contains in insulating covering additives that prevent the active release of suffocating smoke (including the resulting chlorine - after all, polyvinyl chloride) during thermal decomposition. This is relevant when the fire occurs: people die when they cannot leave the zone of fire from suffocation !!!

For this public use and possible large accumulation of people, it is necessary to use cables and wires in the execution of NG-Ls (which the projects of modern structures are required).

The plastic with the properties described is more expensive and this, of course, is reflected at the cost of the cable.

Cables kg.

Abbreviation kg decoded as a flexible cable. CB Cable - copper multi-boosters. The amount lived from two to five. Insulation and shell veins are performed from rubber based on isoprene and butadiene rubber.

The cable is designed to attach mobile and portable devices to electrical networks. The outer shell of the cable has an increased oil-gas resistance, and also has a light-resistance. The cable is resistant to multiple bend, and retains these properties at negative temperatures. Permits operation at ambient temperature -40 ° C? + 50 ° С.

The service life of the cable type is 4 years.

NYM cables.

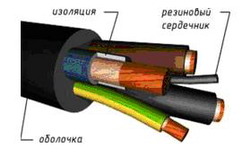

This type of cable, in contrast to those discussed earlier, has an additional inner filler that fills the space between insulated cores under the shell. The filler is performed from a minor-filled vulcanized rubber, which additionally protects insulated veins from possible mechanical damage, and, sharpening when cutting, significantly facilitates the operation when connecting ends. The cable is released only in the twisted (round) version and has a practically round shape.

TPZ - Copper Monasted. Number lived from two to five

Insulating and outer coverings of cables are performed from cable PVC with increased minor compliance. This makes the cable tougher and the surface of the cable is more "slippery". It was these goals that were pursued when developing the design of this cable (the design of NYMA came from Europe) for use in modern building technologies. In addition, elevated minor filtering of cable covers ensures its reduced flammability compared to the WG. However, if the NG and NG-LS properties are required, then it is in these versions and it is necessary to acquire NYM. But for this "pleasure" of course, it will have to pay additionally.

Cable life of 30 years.

Laying outdoors without additional protection against ultraviolet exposure is invalid.

Temperature range of the Environment -30 ° C? + 50 ° C, and with negative temperatures, the cable is more prone to cracking the protective covers when bending than the VG.

This cable is much more expensive compared to the analogues of other brands and types of cables due to the more complex technology of its manufacturer and use of additional materials. However, it is very convenient in the production of large volume. mounting work. The cable is convenient exactly installers !!! The cable is easy to run in pipes, closed and curved cable channels, the cable is easy to cut and connect.

It should be borne in mind that due to the internal filler, the cable will take a larger amount in the cable channel.

All NYMA manufacturers and suppliers declare: NYM meets the highest European standards! The thing is that each manufacturer, the cable is obliged to produce it in accordance with the developed standard for this type of product. Cable and conductor products are subject to mandatory certification. This means that all cables leaving from production are obliged to be accompanied by a "certificate of conformity" and "fire safety certificate". Each supplier of cable and conducting products is obliged at the request of the buyer to present, and if necessary, and give these two certificates !!!

Now about the "height" of the European standard. The design of NYMa is such that it takes into account not only the requirements of the safe and reliable transmission of electricity, but also modern technologies Construction, when cable runs (pipes and closed curved cable channels) are immutted when the walls and floors are erected. The cable in this case is delayed in the track by a special conductor after the completion of construction and installation works. In this case, we can talk about the "height" of the standard on NYM.

In all other cases, the requirements of the European and Russian standards are identical.

Doing the wiring at the cottage I refused to use NYMA - Why should I pay extra money?! Connecting the ends of the wires is made once and with the amount of work of the time gain when using NYMA is negligible. I used the usual VVG - the insulating properties of its covers above compared to the minor plastics of NYMA. NG and NG-LS execution also did not take on what I believe that the wiring should be made competently and correctly, and not operated in extreme conditions, "as close as possible to combat" and fire conditions. Install the wiring should be so that the conditions for the emergence of the fire is excluded !!! The WDG took in a flat design, as it occupies a smaller volume and the cable channel with a lid can be lifted smaller - it looks "prettier".

Cables PVS and ShVVP.

PVS ShVVP

These cables are released only with multi-breed copper CPF with a cross section of up to 2.5 mm?.

This is due to the common and even fixed in the regulatory documents the name of these cables - the PVA is called a wire, and the ShVVP cord.

PVA can contain from 2 to 5 isolated lived, and the SVVP, as a rule, contains two veins (but may be three).

They are intended to connect various household electrical appliances operated in residential and administrative premises (refrigerators, washing machines, lamps, table lamps etc.), as well as for connecting a variety of manual power tools (drills, soldering iron, garden tool, etc.).

Insulating covers are made of cable PVC plasticists, which limits the temperature range of the environment for their operation from -25 ° C to + 50 ° C. Despite these temperatures, boldly indicated by all manufacturers, it should be noted that under the negative temperatures plastic protective covers "Dubet". Why, without prior heating at -15 ° C, it is impossible to be flexing and laying, and you can use the extension from PVA or WWNVP - because I will have to unwind it and wind up !!! Sorry, but I do not understand this !!!

For a correct choice between these two types, keep in mind that the SVVVP is flat and with a length of more than 1.5 m prone to twisting and confusing with frequent unwinding and ware. PVA round, confused less, but heavier and takes a larger volume at the same length as SVVP.

Therefore, if I need to connect a soldering iron, then I will choose the SCVVP (the soldering iron must be kept in your hand on weight and requires accurate work), and if we are talking about the electric drill, I will put the PVA length of five meters (it will not be needed to be the extension. ). Although, to be honest, I connect all your manual power to the cable KG - the wire remains flexible even in the cold and more elastic due to rubber protective covers.

Cables SIP.

Abbreviation SIP decrypt as self-supporting insulated wire.

It is designed to transmit electricity in airlines and branches to homes and economic buildings. Isolated cable veins are simply twisted and the common shell is missing. This is done for the convenience of mounting and connecting. When connected to a single-phase network, a wire twisted from two insulated conductive lives is used, and when connected to a three-phase network, from four. The most common siep with a cross section of three-term 16 mm? It is necessary to use it for branches to your homes and economic buildings.

CWP - aluminum multi-breeding veins, sculitated, as a rule, around steel carrier wire. This allows you to use less supports and suspensions when laying and abandon additional stretch marks for hanging the cable.

Housing insulation is a cross-stabilized polyethylene, resistant to the destructive effects of ultraviolet. This is achieved by introducing into an insulating material of special additives and a special effect on plastic in the manufacture of a cable. As a result, polymer material chains are stitched - additional transverse links are formed. All this in the amount of black isolation provides very high light resistance. In addition, the wires in winter does not occur on the formation of snowy growths and ice !!!

The minimum gasket temperature of the cable without heating is -20 ° C

Permissible temperature mode operation from -50 ° C to +50 ° C.

Cable life of at least 30 years !!!

For the installation of the cable, as well as for connecting to the previously paved air lines of electricity, special clamps and brackets have been developed. If you use - you don't even have to enter the cable !!! Just put the cable into special grooves and tighten the bolts on the clips. The mounting clamps are reliably fixed the cable, and the insulation plugs also pierce the insulation, providing reliable electrical contact with TPZ.

Of course, the cost of the cable corresponds to its properties, as well as the cost of special clamps and brackets. But if you need to solve the tasks that correspond to the designs of the SIP wire - costs will not be in vain when choosing exactly this wire.

And I want to add in conclusion. When choosing cables and protective devices for electricity supply, do it as correct as possible, try to get the most accurate information on your questions. All reasonable costs for your budget will turn out the savings !!! In vain spending it will be the acquisition of incorrectly selected products (and it does not matter, it is dear or cheap) !!!

Previously, only 2 types of information were transmitted on the wires: a TV signal (antenna cables) and telephone conversations (telephone cables and wires). Now information transmitted by metal wires was an order of magnitude more than even 10 years ago, which led to the appearance of a large variety of cables for transmitting information.

Antenna cables

In the image: Cable of RK 75 for television antenna, figures indicated 1 - copper lived, 2 - insulation, 3 - screen from foil, 4 - coppercraft, 5 - PVC sheath.

Now most often use such cables for television antenna: RG-6, RG-59, RG-58 or Russian version of the Republic of Kazakhstan 75. These are coaxial cables that are well transmitting high-frequency signals for the TV and radio. Such a cable consists of central copper veins with a cross section of 1 mm 2, surrounding it isolation from foamed polyethylene, an aluminum foil screen, an external conductor from a coppercraft and a protective shell of PVC.

RG brand cable have many varieties that are distinguished by some technical characteristics.

Computer cables (twisted pair)

In the image: Cable for building computer networks with twisted pairs.

The cable consists of one or more pairs of wires, passing pairs, thanks to which the signal transmission is improved. Each conductor is enclosed in PVC insulation. The cable can be enclosed in a moistureproof shell. In the design of the twisted pair there is a discontinuous thread, thanks to which it is easier to get to the metal lived. There are several types of cables for computer networks:

UTF unprotected, without a common screen for pairs of wires;

FTP. with an aluminum foil screen;

STP. With a common screen made of copper grid and each twisted pair is protected by its screen;

S / FTP. With a shared foil screen and each pair is enclosed.

In cables for computer networks there can be a different number of twisted pairs. The most common cable for these goals SAT5E, which consists of 4 pairs of wires of different color.

Telephone cables and wires

There are 2 main types of telephone cables:

1. Used for laying line to the building;

2. Used to connect subscribers inside the building.

TPPEP The most frequently used cable to connect a large number of subscribers. The cable consists of wiring in pairwise. Housings made of soft copper wire with a cross section of 0.4 or 0.5 mm 2 coated with polyethylene insulation. Outer shell from the same material or vinyl.

If necessary, the varieties of cable are used or in which the internal space is filled with a hydrophobic seal. Cable CTP can be laid almost in any conditions, under the ground, in cable channels or by air.

In the image: Two-core telephone wire TRV.

TRV One or milled telephone wire for laying indoors. This is a flat wire with separated copper single-robes with a cross section of 0.4 and 0.5 mm 2. Insulation from PVC. The wire can be used at temperatures from -10 to +40 ° C, the humidity should not exceed 80% at a temperature of 30 ° C.

TRP According to the characteristics, it looks like a TRV, but is made with polyethylene insulation, so that it is better to transfer the environmental impact and it can be laid outside of buildings.

PCLP Cord for telephone wires of high flexibility with multi-breeding veins. Isolation lived from polyethylene, which are covered with a shell from PVC from above. The amount of 2 or 4 lived, the cross section is from 0.08 to 0.12 mm 2. It is used to hold indoor lines and in telephone sets.

PRPPM Flat wire with copper single-robes with insulation and polyethylene sheath. There is a wire with a PVC sheath. Number 2, section 0.9 or 1.2 mm 2. Used for laying telephone lines outdoors, on air supports, in the ground and walls of buildings. Temperature range for Operation -60 to +60 ° C.

Special types of electrical cables and wires

If planned to operate electricity of the net In conditions of strongly different from normal, special cables and wires must be used.

RKGM Power mounting single-core flexible thermal resistance wire. Copper lived, multi-breeding, cross section 0.75 - 120 mm 2. Cutonic rubber insulation, fiberglass sheath, impregnated with heat-resistant enamel or varnish.

The RCMM wire is designed for rated voltage up to 660 V and frequency up to 400 Hz. Resistant to vibration high humidity (up to 100% at a temperature of + 35 ° C), thermosetics (range of operating temperatures -60 to + 180 ° C). The wire is protected from malicious effects of varnishes, solvents and fungal mold. The perfect conductor for rooms with elevated temperature (boiler rooms) is suitable for wiring in baths, saunas, connecting wind wardrobes.

PNSV Heating single-core wire, served single-robust from venelenny or galvanized steel. The cross section of the vein - 1.2; 1.4; 2 and 3 mm 2. Insulation from PVC or polyethylene. Rated voltage up to 380 V, frequency - 50 Hz. The wire can be operated in the temperature range of -50 to + 80 ° C, it is not afraid of alkalis, it can be immersed in water. Used as a heating element, warm floors are made from PNSV.Runway Single-core copper wire. There lived a multi-breed, enclosed with polyethylene, shell also from polyethylene or PVC. The cross section of the vein is 1.2 - 25 mm 2. Rated voltage 380 or 660 V, frequency 50 Hz. The wire is resistant to pressure change. Range of operating temperatures -40 to + 80 ° C. Most often used for artesian wells, immersed in water under high pressure.

LED cable It consists of conductive veins along which additional wires are placed with successively connected LEDs of different colors. Diodes are usually located at a distance of 2 cm. Such a cable can be used to create luminous solutions of a home or stage interior.

There are still electroluminescent wires that are similar to LED cables. With the help of such wires, you can create glowing inscriptions, it is a more convenient alternative to neon tubes, as the cable is cheaper and unlimited by length.

Additional articles with useful information

Without refrigerator, television and washing machine Life with difficulty seems to be the majority of modern people, but about the rules of operation, thanks to which you can save money and increase the service life household appliances Many do not think.

Many private builder make electric wiring In homes and apartments on their own. Wire selection - a dilemma that occurs almost immediately to make right choice It is necessary to explore the basic properties of electrical wires used in everyday life.

Cable products or cable-conductive products are usually called any kind of uninsulated or insulated conductors, primarily intended for transmitting electrical energy or information, as in computer networks.

Conductive and cable products include insulated and uninsulated cords, ribbons, wires, optical cables with lightweight fibers, tires, cables with metal conductive conductors.

Cord - these are several isolated flexible or particularly flexible sections of up to 1.5 mm, laid parallel or can be twisted, on top of which, again, depending on the operating conditions, a non-metallic shell can be applied and protective

The wire - These are isolated veins or even one uninsulated, on top of which, depending on the conditions of gasket and operation, there may be a non-metallic shell, winding or braid with fibrous materials or wire.

Cable - One or more isolated veins (conductors) enclosed in a non-metallic shell or metal, on top of which, depending on the conditions of gasket and operation, protective cover can be superimposed into which armor can enter.

By type of insulation of power cables distinguishes:

- power cables with plastic isolation;

- power cables with paper insulation, including oil-filled and impregnated;

- power cables with rubber insulation, etc.

Predncable Aznament and Classification

Cables, depending on the material of the transmitted energy conductive, cores or information are divided into two groups:

- Cables with optical fibers.

- Cables with metal veins electric.

Optical cables most often have additional metal conductive conductors. Electrical metal cables are classified by the type of isolation, the magnitude of the voltage, purpose and in many other features.

The magnitude of the linear operating voltage power cables are divided into:

- cables on voltage 1..10 kV;

- cables on voltage 110 .. 500 kV;

- cables for voltage up to 1 kV;

- cables on voltage 20 ... 35 square.

The most important element in all types of cords, wires, cables, is the screen, conductive lived, exterior covers and shells.

Uninsulated isolation wires do not have. Depending on the purpose and operating conditions of the wires and cables, the outer covers, the screen may be absent.

Conductive veins are manufactured either from aluminum or copper. In the last decade, cable manufacturers are based on manufacturing - copper. Aluminum cores are denoted by the letter A. Veins are sectoral (shaped), round, and shaped, infertable.

Marcorazize cable products - Conditional alphanumeric designation, which characterizes in addition to the brand, the main structural and electrical parameters of the cable product: the diameter or section of the conductive veins, the number of veins (groups), voltage wave resistance, etc. and sufficient to distinguish this product from the other.

Cable products - A combination of cable products.

Element of cable products - any structural part of the cable product.

Aggregate - an element that serves to fill the free intervals in the cable or wire to impart the required shape, mechanical stability, longitudinal tightness.

Corde - an element of an insulating material of an arbitrary section used as a placeholder or for the formation of a frame of semi-use insulation.

Strand - the element of the cable winding or braid in the form of several threads or wire adjacent to one other and located in parallel to one row.

Cable winding - Pokrov from the ribbons superimposed along the helix. Threads, wire or strands.

Cable winding with overlapping - Cable winding, which has every turn of the tape covers part of the neighboring turn of the same tape.

Cable winding online - Cable winding, which has the edges of the neighboring turns of the same ribbon, threads, wire, strands come into contact.

Cable winding with gap - Cable winding with which between adjacent turns of the same tape has a gap less ribbon width.

Cable Winding Open Spiral - Winding, which has a gap of the same ribbon between the turns of the same ribbon, threads or wires is more than a ribbon width or thread diameter (wire).

Cable braid - Cable cover from the intertwined strands.

Cable Hearter - Part of the cable (the totality of isolated lived, possibly with the waist insulation and the screen), located under the shell or erane.

Conductive vein - cable element designed to pass the electric current.

Crying conductive core - Conducting vein made from curved material.

Superconducting core - Conducting veins, made of superconducting material.

Stabilizer superconducting housings - The element made of a metal with high heat-controlling, which is in direct contact with superconducting material and shunting the last in moments of loss of superconductivity.

Conductor coaxial pair - conductive element of the coaxial pair of the cable.

Strand - Blank twisted from the wire.

Multi-breed veins - Conducting veins consisting of two or more twisted wires or strands.

Lived proper twist - The multi-propeller lived twisted from the elements of the same diameter arranged by the coaxial oily areas of alternating directions, in the cross section of which the lines connecting the centers of elements of each obstinate form the correct convex polygon.

Lived irregular twist - Multi-breed lived twisted from elements of various diameters. Located coaxial overlooking.

Veins simple twist - Lived proper twist, twisted from individual wires.

Lived bundle twist - Multi-breed veins, wire or stalks of which are twisted in one direction without distribution over the Obaiva.

Round core - conductive veins, in which a cross section or a surface limited by the contour described near the cross section is a circle with an accuracy of the radii of its elements.

Shaped vein - conductive vein, in which a transverse or surface limited by the contour described near the cross section is shaped. Funny from a circle.

Rectangular core - The shaped lived form of a rectangle with rounded corners.

Sectorhore - The shape lived forms of the sector (segment) with rounded corners.

Oval core - shaped veins oval shape.

Hollow vein - lived tubular shape, solid or twisted from round and shaped wire with a reference helix or without it.

Wicker core - conductive lived from wire or strands woven along a specific system.

Spiral core - Conducting lived, imposed on the screw spiral around the core.

Compacted vein - Multi-breed veins, compressed to reduce its size and gaps between wires.

Split core - conductive lived, the cross section of which is separated by insulation into several parts under one potential.

Sealished vein - conductive lived, the gaps between the wires of which are filled with a sealing composition.

Mishur thread - element of conductive veins in the form of a plotted wire. Spirally superimposed on the thread from the insulating material.

Misherior core - Conductive lived, twisted from the Mushroom threads.

Isolated vein - Conducting veins covered with isolation.

Shielded veins - isolated lived, on top of which there is a screen.

Basic core - Isolated live, designed to perform the main function of the cable product.

Zero core - The main liver intended to join the grounded or uncontrolled neutral of the current source.

Auxiliary core - Isolated vein, performing functions other than from the functions of the main livers.

Core grounding - Auxiliary vein intended for connecting not under the operating voltage of metal parts of the electrical device to which the cable or wire is connected, with a storage circuit.

Control core - auxiliary core, serving for control and alarm purposes and part of the conductive core conductors.

Counting - isolated lived, characterized by coloring isolation from all others lived over and designed to be by reference from it the desired core.

Guide core - isolated lived. The distinguished coloring of isolation from all others lived over and intended for determining the direction in which the countdown should be made to find the desired core.

Solid isolation - insulation in the form of a solid layer of dielectric (plastics, rubber, etc.).

Two-layer isolation - solid insulation consisting of two layers of homogeneous or heterogeneous dielectrics.

Plastic isolation - solid insulation from plastics.

Rubber insulation - solid isolation from rubber.

Enamel isolation - solid insulation in the form of a film formed by the enamel varnish or melt resin.

Oxide isolation - Solid insulation in the form of a film of oxides formed on the surface of conductive veins.

Powder pressed insulation - solid insulation of powder based on inorganic compounds.

Mineral isolation - solid insulation of mineral powder.

Film insulation - Isolation of synthetic films.

Paper isolation - Isolation from cable paper tapes.

Upusted paper isolation - Multilayer insulation from cable paper tapes and insulating impregnation.

Impregnated insulation - impregnated paper isolation, the free part of the impregnating composition of which is partially or completely removed.

Fiber insulation - Isolation from natural, synthetic or artificial fibers and threads.

Asbestos isolation - Isolation from asbestos threads.

Delta-asbestos isolation - Isolation from the Delta-asbestos fiber layer and lone-impregnating compositions without them with a lacquered or nonlackated surface.

Insulating impregnating composition - electrical insulating fluid for impregnation of paper and fibrous insulation.

Celed insulation - Multilayer insulation with electrical characteristics specified by the layer to layer.

Lower isolation - Insulation, which is part of the core and superimposed over twisted or unkked isolated housing.

Semipment insulation - Isolation formed by a combination of solid dielectric and air.

Air-paper isolation - semi-use insulation formed by a combination of cable or telephone paper or paper mass and air.

Tubular-paper insulation - Air-paper insulation formed by a ribbon superimposed on a conductive core in the form of a tube is loosely, with the leaving of the air gap.

Mass isolation - Air and paper insulation from porous paper mass superimposed on a conductive core coaxial layer.

Caddle-tube paper insulation - Air and paper insulation formed by Cordell, superimposed on a conductive vein on the screw helix, and winding from one or more tapes.

Air-plastic insulation - semi-use insulation formed by the combination of plastic and air.

Caddle-tube plastic - Air-plastic isolation formed by Cordelem, superimposed on the core or inner conductor over screw helix, and tube or winding from the tapes.

Porous plastic isolation - Air-plastic insulation from porous plastics, superimposed on a core or inner conductor with a coaxial layer.

Caddle insulation - Air-plasmas insulation, formed by Cordelee, superimposed on the screw helix on the inner conductor of the coaxial cable.

Balloon isolation - Air-plastic insulation formed by a periodically chopped tube with an inner diameter, large diameter of conductive il or inner conductor.

Washer insulation - Air-plastic insulation formed by washers located through a certain interval on the internal conductor of the coaxial pair.

Element of twist - Element of the design of the cable product (wire, strand, isolate, the group, group, beam), designed to form a different, more complex, structural element by a twist.

Group - An element of a twist in the form of two or more isolated veins (conductor).

Couple - A group or part of a group of two insulated from each other lived, designed to work in one electrical circuit.

Symmetric para - Couple in which insulated veins of the same design - parallel or twisted - are located symmetrically its longitudinal axis.

Coaxial para - Couple, conductors of which are located coaxially and separated by insulation.

Troika - A group of three isolated veins, located in parallel in one row or twisted.

Four - A group twisted from four isolated lived.

Star Four - Four, in which every two veins constituting a pair are located one against the other on the squares of the square, the vertices of which are formed by centers of conductive livers in the cross section of the four.

Double-paired four - Four, whose veins form two symmetrical pairs with different steps of twist.

Six - A group twisted from three symmetric couples.

Beam - Element - consisting of groups (steam, fours, etc.), twisted in one direction with one step.

Elementary beam - a beam consisting of no more than 20 groups (pairs, fours, etc.) and intended for the formation of the main beam of the core.

Main beam - A bundle twisted from elementary beams and intended for the formation of a core.

Okiv - The layer of elementary twist, located coaxially or with respect to the other similar elements forming together the twisted part of the cable product design (conductive core, core), or on top of the inner with respect to this layer of the part of the cable product.

Enhanced group - A group (steam, four) having a total winding from the tapes of an electrical insulating material.

Shielded group - Group (pair, four, beam), having a shared screen.

Basic Group - Group (pair, four), designed to perform the main function of the cable product.

Auxiliary group - The group is intended for performing functions other than the functions of the main groups.

Accounts group - A group of distinguished coloring isolation at least one of the lived from all

From lived from all other groups, obstacles and intended for locating from her the search group.

Guide group - A group of distinguished insulation isolation at least one of the lived from all from lived from all other groups, obstacles and intended for determining the direction in which the countdown should be made to find the desired group.

Cable screen.- an element from an electrically conductive non-magnetic or magnetic material or in the form of a cylindrical layer around conductive conductors, groups, beam, entire core or part of it, or in the form of a separation layer of various configurations.

Cable shell - Continuous metal or non-metallic tube. Located over the core and intended to protect it from moisture and other external influences.

Metal plastic shell - Cable shell as a plastic tube with a thin layer of metal from the inside.

Reinforcing Pokrov - One or two-layer winding made of metal ribbons or wires imposed on the sheath of the pressure cable to increase its mechanical strength.

Protective cable cover - an element imposed on isolation, screen, shell or hardening cable facility and intended for additional protection against external influences.

Cable armor - part of the protective cover made of metal tapes or one or more obesis of metal wires intended to protect against external mechanical and electrical impacts and in some cases for the perception of stretching efforts.

Cable pillow - The inner part of the protective cover, superimposed under armor in order to protect the element under it from corrosion and mechanical damage with ribbons or armor wires.

Outer cable cover - The outer part of the protective cable cover, superimposed on top of the armor and intended to protect it from corrosion and mechanical effects.

Protective hose. - a solid peeled tube of plastic or rubber, located on top of the metal shell, braids or cable armor and is a protective cover or its outer part.

Protective impregnating composition - The composition for impregnation of papers and fibrous materials that are part of the protective cable cover.

Identification tape - Tape located under the shell or protective cover, on which repetitive designations of the manufacturer or other defining data are applied.

Identifying thread - One il a few threads located under isolation, shell or protective cover and its colors defining the manufacturer.

Measuring tape - The tape located under the shell, divided into certain units of length with the corresponding numbers by which you can determine the length of the cable.

Slip wire - Non-magnetic wire, usually semicircular sections, imposed in the form of a winding open spiral over the outdoor screen of an isolated oil-filled cable, intended for laying in the pipeline, in order to protect the insulation of the cable and alleviate its slip when tightening in the pipeline.

Strategic cable - Cable, wire, cord in which number lived more than three.

Symmetric cable - Cable consisting of one or more symmetrical pairs, triples, fours, etc. groups.

Coaxial cable - Cable, the main groups of which are coaxial pairs.

Three-wire coaxial cable - Cable consisting of three conductors located coaxially and separated by insulation.

Flat cable - cable or wire with a cross section rectangular or close to it, containing one or more veins, located in parallel to one or several layers.

Homogeneous cable - Cable in which the main veins or groups have the same design.

Combined cable - Cable in which different basic veins are designed to perform various functions and have differing designs and parameters.

Cable of revenge twist - Cable, in the core of which insulated veins or groups form bundles, and bundles in turn - core.

Spiral cable - Cable, in the form of an elastic coil spiral.

Self-supporting cable - Cable with a bearing element designed to increase its mechanical strength, fastening and suspension.

Cable with bearing cable - The self-supporting cable, which bears an element of which is steel cable.

Georgeous Cable - Cable or wire, which in addition to its main purpose is simultaneously intended for suspension, tension, as well as multiple descents, lifts, retention at a given height and horizontal movement of goods.

Sealized cable - Cable, the free space between the structural elements of which is filled with a genetic composition in order to obstruct the penetration of moisture into the cable and its longitudinal movement.

Shielded cable - Cable or wire in which all or part of the main lived shielded or has a shared screen.

Cryogenic cable - Cable designed to work in environments having a cryogenic temperature.

Crying conductive wire - Cryogenic cable with cryoprical conductors.

Superconducting cable - Cryogenic cable with superconducting cores.

Power cable - Cable for transmitting electrical energy currents of industrial frequencies.

Cable with viscous impregnation - power cable With paper insulation, impregnated with olokanimphole or similar to it by viscosity with an insulating composition.

Cable with unscrewing impregnation - Power cable with paper insulation, impregnated with insulating composition, the viscosity of which is such that at the operating temperatures of the cable it is not capable of moving.

Cable with waist insulation - A force stranded cable with overall insulation around all isolated twisted or parallel living lived.

Cable with separate shielded cores - Power stranded cable, each vein on top of insulation has a screen.

Cable with veins in separate shells - Silence stranded cable, each veins of which has an independent shell.

Excessive pressure cable - power cable, the insulation of which operates under pressure above atmospheric generated by oil or gas. Included in isolation or being external with respect to it.

Oil filled cable - an excessive pressure cable generated by oil, which is part of paper impregnated isolation, and the temperature changes provided by compensation for the volume of oil.

Oil-filled cable in the pipeline - Oil-filled cable with separately shielded gas, which is part of depletedly or pre-impregnated with paper insulation, and the gas pressure changes provided by compensation.

Gas-filled cable with external pressure - Excessive pressure cable, which is transmitted to gas insulation through an impenetrable shell.

Radiofrequency cable - Cable for transmitting electromagnetic energy on radio frequencies.

Cable matching

Cable delay

Radiofrequency cable for television distribution network.

Radiofrequency cable - Cable for transmitting electromagnetic energy on ridiofatoms.

Cable matching - Radio frequency cable, whose wave resistance varies in length smoothly or steps.

Cable delay - Radiofrequency cable with artificially slow down speed transmission of electromagnetic energy.

Semi-rig radio frequency cable - Radiofrequency cable, retaining its curved state after bending.

Radiofrequency distribution cable - Radio frequency cable for the television network.

Communication cable - Cable for transmitting information signal information currents of different frequencies.

Further communication cable - Communication cable for long-distance communication lines.

Local communication cable - Communication cable for urban and rural telephone networks.

City phone cable - Local cable designed for subscriber and connecting lines of urban telephone networks.

Stational telephone cable - Local cable for laying in the buildings of telephone stations.

Low-frequency cable - Communication cable for which signals are transmitted in the spectrum of tonal frequencies.

High-frequency cable - Communication cable for which signals are transmitted in the frequency spectrum above the tonal.

Telephone cord - communication cord for connecting the telephone with a microthelphone tube and with a wall outlet.

Control cable - Cable for remote control chains, relay protection and automation.

Control cable - Cable for control and measurement chains at a distance of electrical and physical parameters.

Signal locking cable - Cable for signaling and blocking circuits.

Geophysical cable - Georgious control cable, control and signaling for the remote measurement circuits of the geophysical properties of rocks passing during drilling and fishery-geophysical exploration of wells.

Hydroacoustic cable - Combined cable designed to transmit electrical energy, information, control and control signals for hydroacoustic equipment.

Thermock Cable - Cable for the manufacture of thermocouple and transmission of thermoelectro-live force from them.

Heating cable - Cable with high electrical resistance cables, designed for heating various objects.

Winding wire - Wire for the manufacture of windings of electrical devices.

Enameled wire - Winding wire enamel isolation.

High-frequency winding wire - Winding wire with conductive venge-wire wire.

Transposed wire - Winding wire with conductive residential wire velocity, mutual arrangement which periodically change.

Installation wire - wire for low voltage electrical switchgear.

Output wire - Wire for the conclusions of the windings of electrical machines.

Mounting wire - wire for connecting electrical circuits in electrical, radiotechnical, etc. devices.

Ignition wire - wire for aviation, automotive ignition systems, etc. engines.

Thermoelectrode wire - Wire to attach the terminals of the thermocouple to the measuring schemes.

Resistance wire - Wire with a residential alloy of several metals with high electrical resistance.

Ribbon wire - Flat single-layer wire.

Uninsulated wire - Wire consisting of one or more twisted wire.

Contact wire - Uninsulated wire for the suspension contact network of electrified transport.

Hollow wire - uninsulated tubular shape wire.

Style aluminum wire - Uninsulated wire consisting of bimetallic steel aluminum (possibly in combination with aluminum) wire or from a steel core, on top of which wires from aluminum or its alloy are applied.

Nominal number of housings - The number lived in the cable brand.

Nominal size element - the size of the structural element of the cable without taking into account the tolerances set by the regulatory document.

Nominal cable size - The size of the cable, calculated on the basis of the nominal sizes of its elements.

Estimated cable mass - The mass of the cable, calculated on the basis of the nominal sizes of its elements.

Step twist - The distance between two points corresponding to one complete twist of the twist element measured in the direction of the longitudinal axis of the cable.

Step Corrugation Element Cable Product - The distance between the two points is equally located on two neighboring corrugations, measured in the direction of the longitudinal axis of the cable.

Stage laying housing - The distance between the axes of the adjacent conductive veins of one layer in a flat cable.

Long cable circle - The circle passing through the centers of the elements of the twist (wire, strand, lived, groups, beams) forming the observer.

Multiplicity of steps of twist - The ratio of the poverty twist step to the diameter of the circle described around the Oviva.

Theoretical multiplicity of twist steps - The ratio of the poverty twist step to the diameter of the long circle of the cable product.

Skruch's coefficient - The ratio of the outer diameter of the cable product or its billets consisting of homogeneous twisted elements to the diameter of the twist element.

Corner twist - the acute angle between the normal to the line, parallel axis of the cable product, and the axis of the sweep of the element of the twist, provided that all three lines lie in the same plane.

Cable Cable Coefficient - The ratio of the length of the twist element in the twisted cable product (or its workpiece) to the length of the product (billet).

Right direction twist - The direction of the twist (wire armor), in which the element of the twist (wire armor) rises along the helix in the right (left) direction.

The right direction of the winding - The direction of the winding, in which its turns rise in the spiral in the right (left) direction.

Settlement section of the core - The cross-sectional area of \u200b\u200bconductive conductors, calculated based on its nominal sizes.

Nominal cross-section of the core - The cross-sectional area of \u200b\u200bconductive veins, indicated in the marco-sample of the cable product.

The actual cross section of the core - The cross-sectional area of \u200b\u200bconductive veins, determined by measurements.

Coefficient of filling of the core - The ratio of the cross-sectional area of \u200b\u200bthe multi-breed conductive cores to the area bounded by the contour described near it.

Ribbon hood coefficient - The ratio of the thickness of the tape before and after it is applied to the cable article or its element.

Surface density coefficient braid - The ratio of the surface area coated with the inclined material, to the area of \u200b\u200bthe entire surface to which the braid is applied.

Corrugating coefficient of the cable product element - The ratio of the length of the longitudinal forming corrugated element (screen, shell, etc.) to the length of its longitudinal axis.

Corrugated degree of cable element - the ratio of external diameters on the protrusions and varnodes of corrugated elements of cable products.

Construction Cable Length - The normalized cable length in one segment.

Bimetallic wire - Wire, consisting of two (many) layers of heterogeneous metals or alloys that are in a state of molecular clutch.

Wedish wire - Wire, which is an ulusion of giving a linto shape.