What is a monolithic grillage. Pile-grillage foundation: device, pros and cons

Pile foundations with a monolithic grillage have a fairly large number of positive qualities, unlike other types of foundations. This type of support can provide high quality and reliability of the support, while the cost of its construction will be much less than spending on other types of foundation. In addition, a feature of the technology for manufacturing pile foundations with a monolithic grillage is that such supports can be used in almost any area, not only on flat surfaces, but also on weak, unreliable soils consisting of sand or water-saturated soil.

When viewed in a plane, the pile foundation looks like individual piles installed, it does not look like a solid surface or a concrete strip. It is this technology of erecting a support that allows you to arrange a foundation anywhere. They are hammered into the soil to any depth and are additionally fastened with a special strapping, which serves as a retainer for the supports. Pile foundations can be presented in various varieties, including those with a monolithic grillage. A similar design is used in the row arrangement of supports.

Advantages of a pile foundation

A pile foundation with a monolithic slab is often used in construction, as it has a number of advantages:

- Ease of arrangement. Compared to other varieties, the pile foundation is less labor intensive.

- Construction speed. The time required for the construction of pile supports is much less than the time required for the construction of the tape base of the building.

- The consumption of concrete mortar is less than with other types of structural support.

- The need for transport work is significantly reduced, by about 70-80%.

- The risk of structural shrinkage is reduced by about half.

- A pile grillage foundation can be constructed even in winter, subject to technology.

- Significantly reduces the cost of works on the construction of the base. The final price will be 15% less than the cost of arranging another type of support.

Thus, the use of pile foundations is becoming more and more popular and in demand today. This technology is used both for the construction of apartment buildings and large structures, and for the construction of private houses.

Types of pile supports

The device of a pile foundation with monolithic inclusions can be performed in various versions:

- The base with a hanging grillage, the design of which includes a small hole between the grillage and the soil up to one hundred millimeters, due to which the external foundation of the house seems to hang over the soil. This technology is used to protect the monolithic surface from the bad effects of the soil. A similar type of foundation is used by specialists for the construction of structures from various materials.

- With the deepening of the foundation piles in a special monolithic base grillage. With this technology, there is no distance between the base and the soil, but there is a plinth, which is provided precisely by the grillage. When using conventional pile supports, it will not work to equip the basement. The grillage can be made from a variety of options, including concrete, reinforced concrete, wood and steel. The most suitable, durable, reliable and safe option is (according to experts) reinforced concrete.

In order to equip a pile-grillage foundation using a monolithic slab, it is necessary to first perform a number of preparatory work:

- Pick up the piles of the right size, as well as cut the heads of the supports to the right size.

- The upper part of the supports is cleaned, washed well, and then air-dried.

- Formwork construction in progress.

- For the arrangement of removable formwork, it is protected from mortar, usually with the help of polyethylene.

- A monolithic grillage is being poured. Concrete is then poured in successive layers over the surface.

Before starting work, it is necessary to carefully study all the drawings. The work on arranging the foundation of the house is a rather laborious and costly stage in terms of financial resources, so all plans and drawings must be drawn up in advance, and be sure to take into account the terrain and soil quality.

How to equip the pile foundation of the house?

How to equip the pile foundation of the house?

The pile monolithic foundation differs from other types of foundation in the relative simplicity of its construction. For the construction of such a foundation, a certain sequence of actions is required:

- The first step is to study the soil in the selected area. This is necessary in order to determine the bearing capacity of the soil, its ability to withstand the severity of the proposed structure. In addition, the length of the piles, as well as the degree of their penetration into the soil, is also determined by the nature of the soil.

- Further, after engineering research, the main drawings of the future foundation are drawn up, on which the locations of the supports, their length, clogging depth and other parameters are precisely determined. The drawing is a complete section of the future base.

- After that, according to the markings on the drawings, the soil is drilled at the location of the pile. If the supports are already in ready-made form, then they can be introduced into the ground by driving with the help of special construction equipment.

- After installing all the supports, it is the turn of the formwork. In this case, a removable formwork is used, or a wooden structure is made right on the spot.

- If you plan to install a built-in monolithic grillage, then in this case a special trench is prepared for further pouring of the concrete solution.

- After preparing the concrete solution, the grillage and supports are poured.

- The poured solution is left for exactly one month until it dries completely and becomes strong enough.

When performing work, you need to constantly monitor so that the design that is obtained in reality corresponds to what is indicated in the drawings. For this purpose, specialists, as a rule, use a building level and level, which allow you to check the angle of location and evenness of all structural elements.

You can make a pile foundation for the house with your own hands. This may require the following materials:

You can make a pile foundation for the house with your own hands. This may require the following materials:

- Reinforced concrete supports of the required dimensions, depending on the type of soil and the characteristics of the territory.

- Sand or gravel for arranging pillows at the bottom of the drilled hole, if any.

- Special equipment and equipment, if it is planned to equip trenches and wells.

- Concrete mortar for pouring the base.

- Boards and nails for the construction of formwork.

In general, the process of building a pile foundation is not so complicated. If the arrangement of the foundation is carried out for a future private house of small size, then the piles, as a rule, are not selected too large. Therefore, they can be easily installed without the involvement of additional large equipment. In fact, the construction of a pile foundation turns out to be simpler than the arrangement of a tape or monolithic foundation.

Types of supports and their characteristics

In order for the foundation of the house to be as reliable and durable as possible, it is necessary to carefully select the piles for the foundation. Today there are a large number of varieties of supports, the length of which can be from three to six meters.

In order for the foundation of the house to be as reliable and durable as possible, it is necessary to carefully select the piles for the foundation. Today there are a large number of varieties of supports, the length of which can be from three to six meters.

Piles can differ according to the following characterizing points:

- The material from which the supports are made.

- Piling manufacturing method.

- Section type.

- The method of deepening the pile into the soil.

Depending on the method of introducing piles into the ground, the following types of supports are divided:

- Drilling supports made of reinforced concrete, which are installed in ready-made drilled holes.

- Screw supports, including drills.

- Driven supports that are driven into the ground by hammering or plunging with a hammer and vibration.

- Stuffed supports, made mainly of concrete or reinforced concrete, which are inserted into finished wells and then poured over with concrete mortar.

In addition, piles can be divided into single, ordinary and cluster, depending on the method of location of the supports in the foundation area. The strength, reliability and durability of the entire structure depend on how well the piles for the foundation were chosen.

A grillage is the upper part of a pile foundation that distributes the load from the load-bearing elements of a building (structure). As a rule, this is a reinforced concrete frame under the bearing walls of the building and standing on driven piles, resembling a table from the side. The grillage on piles is made in the form of beams or slabs that unite the pile heads and serve as a supporting structure for the building elements being erected.

In the construction of low-rise houses and cottages, pile foundations with a grillage are widely used as a foundation. In these cases, most often the design is a monolithic tape. The foundation of a house on reinforced concrete piles is used where the use of other types of foundations is irrational. On soft soils, the load from the house must be transferred to deep soil layers, which are denser and have better bearing capacity. It is this task that reinforced concrete driven piles under the grillage solve. Such a foundation is also being erected in areas with a depth of soil freezing up to one and a half meters. When building on difficult terrain, a foundation with a grillage on reinforced concrete piles is the only possible option.

Types of grillage on reinforced concrete piles

Grills of pile foundations are classified depending on the technology of their manufacture:

- Monolithic grillages- concrete tape with reinforcement connecting all the upper ends of the piles. Such a grillage is constructed in the same way as a conventional strip foundation, however, in some situations it does not look like separate strips, but a solid slab. For the construction of a strip pile foundation, much less building materials and time will be required than for pouring a slab base. In this case, the pile heads are tied with a grillage only along the perimeter of the future house, and sometimes (if the base area is large) the perimeter is tied with an additional transverse tape. It is cheaper and easier to build a strip foundation than a pile tiled grillage. The difference between pouring a monolithic slab base lies not only in the increased consumption of the concrete mixture, but also in the greater labor intensity of the process. The slab will require a solid formwork, which, in addition to the side walls, needs a strong base that can support the weight of the entire reinforced slab. Tying the reinforcement along all the heads of the supports will not only take a lot of time, but will also require patience. Therefore, if it is permissible according to the calculated strength indicators, a pile foundation is erected with a tape-type grillage.

- Prefabricated grillages- mounted from standard reinforced concrete beams. It is assembled from several ready-made elements of a special configuration (locks are provided), which are then monolithic. Separate elements of the prefabricated grillage, if it is planned to manufacture a monolithic reinforced concrete structure, are laid on top of a specially arranged sand embankment, which is removed upon completion of the work.

- Prefabricated-monolithic- combined grillages.

The dimensions of the pile foundation grillage are selected constructively. Its width usually corresponds to the width of the plinth or, if one is not provided, to the width of the wall, but not less than 40 cm.

In addition, grillages differ in the level of location above the ground:

High grillage on reinforced concrete piles - transfers the load from the building through the piles to the deep layers of the soil. A pile foundation with a high grillage is built on strongly heaving soil, since with such a design the effect of frost heaving forces on the base of the grillage is completely excluded. There is a well-ventilated space under the building with a high grillage. In hot climates, this feature can be considered an advantage, in cold climates - a disadvantage. To minimize the negative impact of drafts, the floor insulation is increased, and the gap between the grillage and the ground is covered with shields.

Low grillage on reinforced concrete piles - it partially takes on the load itself if it rests on the ground. Such a grillage is placed above the ground, so that there is a gap of 10–15 cm between its lower edge and the ground. With this design, measures must be taken to prevent the soil from falling into the trench. If this is not done, the space under the grillage will eventually fill with earth and in winter the grillage will come off the piles.

recessed grillage on reinforced concrete piles - they are placed in a trench 30 - 40 cm deep. With this option, the creation of a monolithic grillage is simplified (the trench replaces part of the formwork), and the floors of the first floor are not so cold.

The sequence of the construction of the grillage on reinforced concrete piles

- Site clearing. The upper fertile layer of soil is removed so that plants do not grow under the foundation.

- Construction of a pile field.

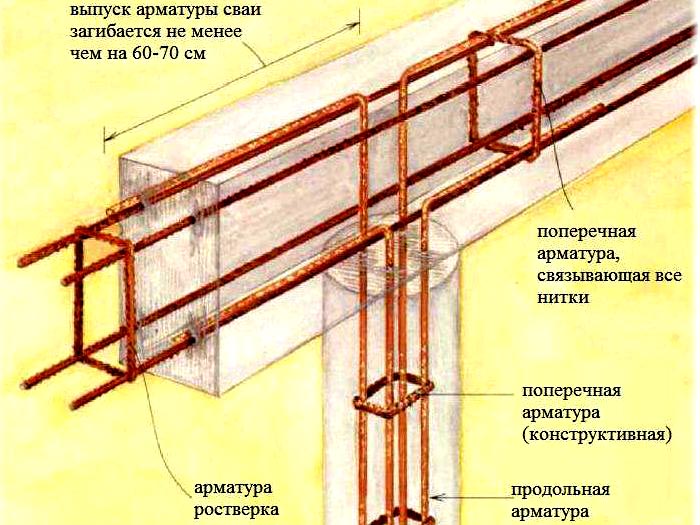

- Assembly and installation of the reinforcing frame of the future grillage. The frame structure must consist of at least two rows of horizontal bars connected by vertical reinforcement posts. The distance between the vertical posts is 30-40 cm.

- Fixing the frame on piles, paying special attention to the corners of the future foundation. Reinforcement at the corners is bent in different directions. The contour of the reinforcing frame must be completely closed around the perimeter.

- Erection of formwork for pouring a monolithic tape. If a hanging (above-ground) grillage is being erected, then additional supports are installed between the piles under the formwork. This equally applies to the grillage in the form of a monolithic slab.

- The last stage in the construction of a pile monolithic grillage is the preparation of concrete and pouring it into the formwork.

Advantages of foundations on reinforced concrete piles with grillage

The advantages of a foundation with a grillage on reinforced concrete piles include:

- High reliability of the foundation,

- The minimum front of earthworks,

- Low consumption of building materials (the need for concrete is reduced - when the grillage is above ground, laying concrete pillows in trenches is excluded),

- Possibility of work in winter (installation is not canceled even at temperatures below -10°),

- No subsidence of soil during swelling or flooding,

- Reducing heat loss - by reducing the area of contact with frozen soil,

- Reducing the cost of work up to 20%,

- Reduction of foundation construction time.

Order a foundation on driven reinforced concrete piles with a grillage

A driven foundation with a monolithic grillage occupies a worthy place among other types of foundations for a house. It is a reliable design with a large margin of safety. For all types of houses built in the private sector, we recommend laying a pile foundation with a grillage with a monolithic bonding tape, since the endurance of a one-piece structure is much higher. Price, speed, reliability - the combination of these qualities is the basis of the grillage on reinforced concrete piles.

We will send the material to you by e-mail

Before building a house and deciding which foundation to create - or a pile foundation, novice builders are faced with such a thing as a grillage. Below we will consider what a grillage is and its necessity when arranging the foundations of a building.

General view of the monolithic structure

A grillage is a horizontally located element of the pile foundation of a structure (a kind of belt or pillow), which takes on the entire load of the building and, evenly distributing it, transfers it to the supporting columns. This is achieved by tying the piles into an integral structure. Since the grillage on the pile foundation increases the strength of the building, it is necessary to provide sufficient rigidity to all joints.

The advantage of such a foundation for the building lies in its durability, strength and the possibility of building on sandy and clay soils, as well as on quicksand. In addition, due to the insignificant amount of preparatory work and the concrete mortar used, such a construction of the base of the house is considered a less expensive option compared to other types of foundations.

To better understand what a grillage is, you need to know its classification according to the following types:

- at the place of arrangement;

- on the building materials used;

- by design decision.

By location:

- Shallow. This is the optimal type of construction for obtaining reliable stability. Since the sole of the belt is built directly on the ground, the entire future load from the structure will be distributed not only between the piles, but also on the entire foundation.

- Buried. In this case, a part of the structure with a sole width of 50 cm or more enters the ground. These are used for construction, on unstable soils, of buildings with several floors.

Video: grillage device for a wooden house

Metal belt for the foundation

The metal crate is made of a channel, I-beam or square profile and has high strength and rigidity. As a rule, this design is used when arranging pile-screw foundations for. The channel is installed on the heads of the supports, and fixed by means of a welding joint.

A metal belt is used mainly in a hanging version. However, recently such structures have been used very rarely, because due to the severity of the material, special lifting equipment is required, which is economically unprofitable. In addition, the metal is at risk of corrosion processes.

Types and purpose of grillages

Grill structures differ in type and purpose. When choosing the right design, many factors are taken into account.

Strip foundations with grillages

For buildings, a fairly strong and reliable support is pile foundations with a strip grillage, for which two technologies are used. One of them is used in the arrangement of foundations above the ground level, and the second - at the stage of creating a lattice structure, which takes on part of the load.

A strip foundation is the best option for arranging a foundation on slopes and areas with difficult terrain, since it does not require complex preparatory work to plan the site with the involvement of special equipment. This design is perfect for the construction of structures made of lightweight materials.

Using a strip foundation during the construction of a house, it is necessary:

- Sand cushion, the thickness of which is 200-300 mm. It is created under the concrete frame and piles to protect them from the damaging effects of ground moisture.

- Waterproofing of the lattice and supports, for which polyethylene film, roofing material or asbestos-cement pipes are used.

When arranging the foundation, it is necessary to carefully in the tape grillage, as well as its thickness and other parameters.

For fence

The grillage device for fences is necessary for the full protection of the structure, which the fence plane cannot provide. The creation of the belt is due not only to protection from external factors, but also to ensure that, for example, pets cannot get out of the site. The reasons can be any, but the execution must always be of high quality, ensure the strength and durability of the structure.

In principle, the grillage under the fence practically does not differ from the belt used in the arrangement of the foundations of houses. The same design, building materials are used here and similar functions are performed.

For pile foundation

The need for a columnar foundation with a grillage is determined directly by the specific design of the building, its weight and the rigidity of the structure frame. In order for the supporting columns not to collapse, they are obligated to have a monolithic reinforced concrete, metal or even wooden belt.

In construction, several schemes of the pile foundation of buildings are used:

- Columns with a hinged belt are buried in the ground. This scheme is used in 90% of all pile foundations;

- The pillars rest on a crushed stone embankment without deepening into the ground. With this scheme, high rigidity of the base of the house is ensured, which allows you to minimize the likelihood of subsidence of the structure;

- Without grillage. This option is used for the construction of small houses.

On a note! Supports for the columnar base of the building can be combined, for example, brickwork is combined with pouring concrete mortar or a base of building rubble. In principle, the properties of the foundation do not change from this, but the process of arrangement is greatly simplified and the cost is reduced.

Pile-grillage foundations

Grill technology with bored piles

Arrangement of foundations with a grillage on bored piles is mandatory when building buildings on uneven terrain, slopes and unstable soils. These designs are the best option for the construction of both small houses and capital structures of medium size. Bored foundations with a grillage have a bearing capacity higher than that of monolithic and strip foundations, and they are cheaper.

Bored piles, able to carry a load of about 1500 kg. For the construction of a medium-sized structure, several dozen columns will be needed, the diameter of which can reach up to 150 cm and the length up to 40 m.

For the arrangement of the base of the building does not require major earthworks. Each pile is waterproofed with two layers of roofing felt or roofing material and fixed in a non-freezing layer of soil. Waterproofing allows you to protect concrete from destruction and reduce soil pressure on the supports.

Advantages of the base on bored supports:

The tops of the installed pillars are cut at the same level, after which they are combined with a common belt. Grillage on bored piles allows for uniform distribution of the load exerted by the weight of the structure over the entire base of the building. The device of the pile-grillage foundation can be seen in the video below:

The disadvantage of this design is the fact that due to the presence of free space between the floor and the ground, the bored foundation with the grillage needs to be insulated. This leads to additional labor and material costs.

Grill on screw piles

The advantage of foundations on screw piles is that they do not require excavation, and they are usually used on clay and heaving soils. After the supports are installed, their heads are cut into one level and a lattice belt is made.

Monolithic reinforced concrete and concrete structures for screw piles are extremely rare, since this type of support is used to build light structures. Most often, a pile-screw grillage is made of a metal corner or channel.

Before installing the grillage on the heads, metal platforms are welded to them, the size of which should allow the axial displacement of the supports to be corrected. Further, a channel or a corner is used to tie all the piles, as a result of which a strong and reliable structure is created.

Important! Before the installation of the foundation and grillage on screw piles, it is necessary to carry out anti-corrosion treatment of all metal structural elements. This will significantly increase the life of the structure under construction.

Main dimensions and dimensions

To create a strong and durable foundation, it is necessary to make the right calculations. The shape and dimensions of the grillage used are determined by the design features of the building being erected, the loads on the foundation, the number and location of piles.

The grillage is created, as well as the design of the strip foundation. The height of grillages for pile foundations directly depends on the level to which the building should be raised from the ground, as well as on its weight. You can independently perform the calculation of the structure, based on the ground or slightly recessed. In the case of a hanging belt device, it is better to entrust the calculations to specialists, since for a non-professional they are very difficult.

- B - the minimum allowable height for the support of the belt;

- M - the weight of the structure of the structure, excluding the supports used;

- L - belt length;

- R - the strength of the soil near the surface of the earth.

Reinforcing cages for belts on a pile foundation are created, as well as for a structure on a strip foundation. It is necessary to carry out longitudinal (working), horizontally and vertically transverse reinforcement in the structure. The total cross section of the longitudinal reinforcement must be at least 0.1% of the section of the belt. To select the cross section of each rod and their even number, a rebar assortment is used.

The main manufacturers and typical series of pile grillages

For private or small buildings, you can make lattice belts yourself directly at the construction site, but when erecting industrial buildings, multi-storey buildings, etc. use factory-made designs. Among the main manufacturers of reinforced concrete grillage from 35 tons, the following companies can be distinguished:

- JSC APSK "Gulkevichsky" ;

- CJSC "OBD" ;

- CJSC "T-Beton" ;

- LSR LLC. Construction-Ural» ;

- LLC "ZKPD Tomsk House-Building Company" ;

- JSC "PZSP" .

| Series | Description | |

|---|---|---|

| Monolithic reinforced concrete grillages Series 1.411.1-1/89 | For the installation of bases for prefabricated reinforced concrete columns of one- and multi-storey industrial buildings of the II 20-1/70, II 20-2/70, II 20-3/70 series. | The supports of structures of the II 20-1/70, II 20-2/70, II 20-3/70 series have a section of 400*400 and 400*600 mm. and must be embedded in the foundation by 600 mm. |

| Series 1.011-6 | Manufactured from heavy concrete class B 12.5 | Square piles 300*300 and 350*350 mm. |

| Series for grillage made of metal: 3.407.9-1581 | For operation of the structure at a temperature: ● up to -40˚C grillage is made of carbon steel grade Vst 3, corresponding to GOST 380-71; ● below -40˚C for the grillage use low-alloy steel grade 09G2S, which complies with GOST 19281-73 and 19282-73. |

|

The name, which denotes typical grillages for pile foundations, includes the mandatory letter indices RS and RB and serial numbers. Markings RS1 - RS5 are used on square supports, and RB - for rectangular piles.

Important! If it is necessary to order grillages from 50 tons, the manufacturer of reinforced concrete products must be chosen very carefully to guarantee the strength and durability of the entire structure.

Basic provisions for the device and calculation of the pile grillage

When constructing a pile-grillage foundation, it is necessary to know the basic requirements for the grillage and carry out competent calculations of the entire structure. It is also mandatory to have an executive scheme for grillages, on which all the main structural elements are indicated. An important point in designing the foundation of a building is the exact calculation of the required number of supports for each specific type of structure. The calculation is based on the total weight of the structure and the bearing capacity of the soil. The mass of the house must be divided by the bearing capacity of the soil and, we get the value of the area of the designed base. To determine the margin of safety, the foundation area should be increased by 30%. To calculate the required number of support columns, the base area is divided by the volume of each pile, while the following conditions must be met:

- supports must be installed in all corners of the structure under construction;

- piles are mounted at the intersection points of the walls of the building;

- according to SNIP, the distance between the piles in the grillage is 2-2.5 m.

The connection of the pile with the belt can be rigid or loose. In the case of a free connection, the heads of the supports enter the grillage to a depth of 50-100 mm. This type of fastening is suitable for centrally loaded support columns.

With a rigid connection, the pile head is broken, and the reinforcement is exposed, after which it is embedded in a concrete or reinforced concrete grillage. This type of fastening is performed in cases where:

- the installation of pile foundations with grillages is carried out on unstable soils;

- horizontal loads are placed on the supports;

- combined or inclined supports are installed at the base;

- supporting columns work on pulling loads.

Calculation example

Consider an example of calculating a pile foundation with grillages for a one-story brick house with a hip roof made of metal. The building has two reinforced concrete floors 220 mm thick. The dimensions of the house in terms of plan are 6 * 9 m, the thickness of the bearing walls is 380 mm. The total floor height is 3.15 m, from floor to ceiling is 2.8 m, and the total length of the partitions inside the building is 10 m (there are no internal walls in the premises). At the site there is a hard-plastic mixture with a porosity of 0.5 and a depth of 3.1 m.

We pre-set the width of the grillage to 400 mm. and a height of 500 mm. The length of the support is 3 m, and the cross section is 50 cm. We focus on the pitch of the supporting piles - 1.5 m. To determine the total number of piles, it is necessary to divide the length of the grillage by the pitch of the supports and add 1 (if necessary, round the resulting value down to a whole numbers - 30 / 1.5 + 1≈21).

- Support area, m 2 3,14*0,52/4 = 0,196

- Perimeter, m - 2*3,14*0,5 = 3,14

- Mass grillage, kg- 0.4 m. * 0.5 m. * 30 m. * 2500 kg / m 3 \u003d 19500

- Mass of supports, kg- 21 * 3 m. * 0.196 m 2 * 2500kg / m 3 * 1.3 \u003d 40131

- Mass of the building, t- Weight of supports + grillage weight + sum from the table ≈ 224

To calculate the volume of the grillage and other parameters, it is necessary to determine the mass of the structure without foundation supports. As a result, we get M \u003d 204 tons. The width of the salting is M / (L * R) \u003d 204 / (30 * 75) \u003d 0.09 m. Such a belt cannot be used for construction, in this case, since the overhangs of brick walls should not more than 40 mm. Therefore, we assign the width - 400 mm, and the height remains - 500 mm.

Article

Do-it-yourself pile grillage foundation is most in demand among the owners of suburban areas. In dense settlement development, it is impossible to use heavy special equipment (heaps, pile drivers) to drive driven piles with an estimated length of more than 10 m or for light buildings. Renting this equipment is expensive, therefore, short bored piles of a hanging type are used with a tying with a monolithic grillage.

Due to the variety of construction technologies, materials used for pile-grillage foundations, there is a special terminology:

- base - a layer that perceives a vertical load, lying below the freezing mark;

- pile - a vertical structure made in the soil or immersed in it;

- pile field - a group of piles for one structure, building;

- grillage - a monolithic or beam structure along the pile heads (slab, lattice, frame or beam);

- low grillage - buried in the soil or located at the zero mark;

- high (hanging) grillage - raised above ground level;

- the bearing capacity of a pile is the sum of the soil resistances on the side surfaces and under its lower end.

According to the material, bored piles are classified as follows:

- composite - reinforced concrete inside a steel or polymer fixed formwork (large diameter pipe);

- rubble-concrete - in the lower part of the pile, stones are sunk into concrete (maximum size 15 cm, strength not lower than the calculated concrete grade), the upper part (0.5 - 0.7 m) is filled with clean concrete, reinforcement is usually along the entire length (except backfilling);

- reinforced concrete - the pile is completely filled with concrete with reinforcement along the entire length (usually not stressed);

- concrete - reinforcement only in the upper part for tying with a grillage.

The pile shaft can be made in several ways, even when using the same materials. For example, if a hole in the ground is filled with concrete with a reinforcing cage placed inside, the pile will be shellless.

Scheme of a pile with an extension - TISE.

If the pile reaches the bearing layer, is poured into a polymer or metal pipe that does not bear loads and remains in the well for the entire period of operation (non-removable), acting as a waterproofing, a pile with a shell is obtained.

If the temporary formwork is removed after pouring, the pile is called in a temporary shell, the method is a vertically moved pipe VPT. If the formwork remains inside the well and performs load-bearing functions, the pile is called pipe concrete.

To increase the bearing capacity, the base of the pile can be widened with a monolithic base. The sole is drilled with a special tool, an explosion or concrete piles. In a common grillage, the head of a bored pile can have a sliding interface or a rigid embedment into a monolith.

If during the geological exploration of the site the occurrence of the bearing layer deeper than 3 m is revealed, the bored piles-pillars will cost the individual developer more than the screw foundation of the SVF or the floating slab. In this case, hanging piles are more effective, the bearing capacity of which depends on the density and porosity of the soil. If the friction forces on the side surfaces are insufficient, other foundation options should be considered.

Unlike a strip foundation, the depth of the grillage does not depend on the characteristics of the soil:

- the tape rests on the ground with the sole, there are lateral shear loads from heaving forces;

- the grillage does not rest on the ground, it is created exclusively for tying piles, distributing loads, supporting wall materials (especially important for foam blocks, bricks).

After pouring a monolithic grillage, an air gap is created between the soil and its sole to compensate for heaving forces. In low grillages, it is protected on the sides with sheet materials to avoid shedding of the earth, filling this space with heaving soil.

In view of the foregoing, a monolithic grillage along the heads of bored piles is effective in the following cases:

- light buildings - budget savings of 30 - 50% in comparison with a slab, strip foundation for log cabins, half-timbered, frame, panel (SIP technology), panel cottages;

- complex terrain - slopes with a height difference of more than 1.5 m in the building spot;

- high GWL - piles can be poured into the shell with a slight rise in water or by temporarily pumping it out of the well;

- swamp, coastal zone - earthworks for other types of foundations are not possible.

Piles are economically efficient in individual construction only at a depth of up to 3-5 m, which is usually sufficient for light structures. With normal geology on flat areas, piles reduce the budget for the construction of brick, concrete buildings by half. Only in this case, the foundation meets the requirements of SP 24.1333, which regulates the design of pile foundations.

Step-by-step instructions on the example of a monolithic grillage on bored piles

To build a foundation of this type, an individual developer needs to determine the main dimensions of the elements: the cross section of the grillage (height, width), the depth of the well, the parameters of the armored belt, the type of formwork. After that, the amount of building materials is calculated. For convenience, the following is a step-by-step instruction describing the key points.

Geological surveys, calculation of parameters

Unlike screw piles, for which it is often enough to test drive in a building patch in several places to determine the depth of the bearing layer, full-fledged geological surveys will be required here. According to SP 24.1333, this will require a set of operations:

- soil testing by static loads;

- pessiometry, dynamic and static sounding;

- laboratory analysis of groundwater, soils from different layers during drilling 3 m below the design level.

In addition, experts will take into account the impact of piles on nearby buildings and the environment. The result of the survey is a geological section, in which the thickness of each layer is visible, the layers of different rocks present in the development spot. This allows you to select from the relevant tables of the joint venture the standard values of the bearing capacity of clay, sand, loam to calculate the bearing capacity of the pile.

For example, for soil conditions of 2 m high-plastic loam, 1 m hard loam, on top of wet sand, there are several options for bored piles:

- A - the depth of the piles is more than 3 m (passage of loam with the sole resting on the sand), diameter 0.5 m;

- B - depth 3 m, diameter 0.4 m;

- B - depth 2 m, diameter 0.5 m.

For reinforcement, bars of 10 - 12 mm with a periodic section are used. Clamps are bent from 6 - 8 mm smooth reinforcement. For strapping, it is better to use annealed wire. The pitch of the horizontal clamps is 30–60 cm, the rods should protrude 30–40 cm above the heads.

Filling and waterproofing

The formwork for the grillage begins to be assembled from below.

Due to the large volume of concrete work, the pile-grillage foundation is usually poured in stages. First, the mixture is placed in the pile formwork, compacted with a deep vibrator or reinforcing bars to remove air. The grillage formwork is mounted after the piles have gained at least 50% strength (3-5 days after pouring). The technology looks like:

- deck installation - only for a hanging grillage, holes are cut in the shield according to the size of the piles, it is put on the heads, supported by H-shaped racks along the entire length;

- installation of side shields - they are attached to the deck, burst with bars or studs, the upper side should be 5-7 cm higher than the design mark;

- reinforcement - two belts of bars 10 - 16 mm of reinforcement with a periodic section, fastened with clamps 6 - 8 mm, bend at the corners, at the junction of the walls.

Reinforcement grillage.

Filling takes place according to standard technology with laying, vibrocompaction of the mixture. The entire formwork must be filled in one go. Concrete care consists in protection from waterlogging (covering with a film from rain), drying out (sand or sawdust on the upper edge of the grillage with periodic moistening in the first three days).

It is produced after stripping the grillage in several ways:

- impregnation with penetrating compounds (the resource is similar to concrete structures, no repairs are required);

- coating with bituminous mastics (resource 15 - 30 years, budget option);

- pasting with roll materials (the resource of glass hydroisol is 30–50 years, the need for sealing joints, the use of 2–3 layers).

Impregnation waterproofing or a set of measures for the last two options (coating + gluing) is preferable.

Blind area and storm water

For any foundation, regardless of its design, a blind area is required, which has a 4 - 7 degree slope from the building to the outside. This structural element allows you to divert rain, melt water from concrete structures under a monolithic low grillage, underground high grillage. To prevent runoff from destroying the soil adjacent to the blind area (usually a fertile layer), storm water inlets are integrated into its outer perimeter (they take water from the roof drain) and trays that transport liquid to a separate underground reservoir.

To reduce heaving forces under a monolithic grillage, which exert pull-out loads on piles, at a depth of 40–70 cm. To do this, extruded XPS expanded polystyrene is laid on the bottom of the trench. The width of the blind area should be 5–10 cm more than the projections of the roof slopes, so that when the gutters of the roof drain overflow, the water does not destroy the fertile layer.

In the standards of SP 71.13330 of 2011, a blind area width of 0.7 - 1 m is recommended for sandy, clayey soils, respectively, with a tight connection to the fence (false base) of the pile-grillage foundation. It is made from waterproof material.

- concrete screed 5 cm thick in the thinnest sections;

- paving slabs / paving stones;

- rubber or PVC tiles;

- composite decking.

A budget option is a blind area made of dry asphalt concrete mixes used to repair roadways, lining garden paths. It is compacted with a rammer, does not require heating, melting, and increases strength over time.

Following the above recommendations, even an individual developer who does not have a special education will be able to make a pile foundation with a monolithic grillage with a minimum budget without errors. The resource of underground structures, when properly calculated, is not inferior to other types of foundations, while maintaining high maintainability, the possibility of increasing the usable area during operation.

In our articles, we have repeatedly talked about various foundation designs, how they are arranged, for which buildings they are more suitable, how to independently calculate the foundation. We also wrote that one of the most economical foundations for light frame houses, for houses made of aerated concrete or logs, is a columnar or, as it is often called, a pile foundation.

In this article, we will tell you about how to make a monolithic concrete grillage for a pile foundation how to properly reinforce and insulate it.

By its design, a grillage is a concrete, metal or wooden strip, which is attached to the top of a columnar foundation or foundation on screw piles. The main task of the grillage is to redistribute the load from the entire structure to the piles, which in turn transfer it to the ground.

For example, during the construction of a log house, its lower logs, which lie on the pillars, perform the function of a grillage. In frame housing construction, the lower trim of the house also performs a similar function.

We will not consider wooden or metal types of grillage, they are made quite simply, but a monolithic concrete grillage requires a more professional approach.

By this time, piles should be installed on the site. It does not matter what they will be - lined with bricks or poured with concrete.

For the formation of formwork, edged boards with a thickness of 2.5 cm or more, chipboard, OSB, plywood and any similar material are suitable.

Once the entire volume of material has been prepared, you can begin to collect the formwork. It is important to know that the height of the grillage must be at least 30 cm, and the width at the base of the tape is 10 cm more than the width of the pile.

In shape, the grillage is made in the form of a rectangle or in the form of an inverted trapezoid. It can also be made stepped, while the top should be a little wider.

Consider in stages one of the most popular formwork options.

1. The first thing to do is mark the edges of the future formwork and hammer wooden bars with a section of 5x5 cm along this line every 50-90 cm. The bars should be placed strictly vertically.

2. The bars driven into the ground must be securely connected at the top using the same bars. You can use wire for this.

Further, with the help of self-tapping screws, the lower bar is screwed. For this, boards 3-4 cm thick are suitable. The lower part of the entire formwork will lie on these planks.  3. The next step is to install the boards. First, the boards are laid horizontally. Here you need to carefully cut the holes for the piles. The tighter the formwork is pressed against the posts, the less concrete will flow out.

3. The next step is to install the boards. First, the boards are laid horizontally. Here you need to carefully cut the holes for the piles. The tighter the formwork is pressed against the posts, the less concrete will flow out.

After that, the boards are placed vertically. In order for them to hold securely, they are nailed to vertically standing bars, which were driven in at the first stage.  4. As soon as the formwork is assembled, a plastic film is spread over the entire inner surface. It prevents the leakage of cement laitance, which is necessary for the proper maturation of concrete. The film can be shot with a stapler so that it does not fall.

4. As soon as the formwork is assembled, a plastic film is spread over the entire inner surface. It prevents the leakage of cement laitance, which is necessary for the proper maturation of concrete. The film can be shot with a stapler so that it does not fall.

This completes the assembly of the formwork frame.

If you are not sure about the reliability of the design, then you can add additional stiffeners and various stops.

Reinforcement grillage

Concrete is a very strong material, but, as you know, it works well in compression, and bursts when stretched and bent. To eliminate this shortcoming, it is reinforced. Reinforcement, on the other hand, behaves well in tension. Thus, these two materials being together form a strong and reliable construction.

Concrete is a very strong material, but, as you know, it works well in compression, and bursts when stretched and bent. To eliminate this shortcoming, it is reinforced. Reinforcement, on the other hand, behaves well in tension. Thus, these two materials being together form a strong and reliable construction.

The reinforcement of the grillage consists of several stages.

1. First, bars are laid on the bottom of the formwork. Their thickness should be the same. Bars 3-5 cm thick will do. The width is not important here.

What is it for?

According to the rules, the reinforcement should be no closer than 3 cm from the outer concrete surface, i.e. it must be completely sunk into the concrete. Thus, the bars, in this case, are stacked for convenience.

2. Laying the bottom row of longitudinal reinforcement.

To do this, use ribbed reinforcement with a diameter of 10 mm or 12 mm, which is placed on the bars. How to calculate their number, we will consider in the example below.

3. At this stage, it is necessary to tie the longitudinal reinforcement together so that the distance between the individual rods is the same.

For the bundle, smooth rods 6-8 mm thick are used because they are cheaper and do not perform any other function as giving geometry to the frame.

Thus, the bottom row of the reinforcing cage is fully assembled and you can start assembling the top row.

4. Assembling the top row. We will look at one of the ways how you can assemble the top row.

As we wrote above, the bars driven into the ground were connected from above with a bar. Reinforcing bars are hung on these strips using wire. The height at which the reinforcement should hang depends on the height of the grillage. At the same time, do not forget that the reinforcement in concrete should be located no closer than 3 cm from the edge.

Thus, the armature is suspended.

5.Now you need to tie the bars of the top row together. This is done in the same way as the bottom row.

6. It turned out two rows: upper and lower. They are also tied together with smooth rods of 6-8 mm.

7. As a result, a reinforced rectangular frame should be obtained. Since the upper bars were hung on a wire and both rows were interconnected, the wooden blocks that were laid at the first stage can be removed.

It turns out that the entire frame weighs on the wires. At this stage, the reinforcement can be considered complete.

Calculation of the number of reinforcing bars

According to the general rules, the cross-sectional area of the longitudinal reinforcement should be at least 0.1% of the cross-sectional area of the grillage.

As an example, let's take a grillage with a section of 40x40 cm. Let's translate centimeters into millimeters and calculate the area. It will be 160000 mm 2. Accordingly, the total cross-sectional area of \u200b\u200bthe reinforcement is 160 mm 2.

We also know that a suitable rod diameter is 10 mm or 12 mm, while their number in the upper and lower rows should be the same.

The area of a round bar is found by the well-known formula S=πd 2 /4. Where d is the reinforcement diameter.

We get: S 10 \u003d 78.5 mm 2, S 12 \u003d 113 mm 2.

By dividing the total cross-sectional area of all the rods by the area of \u200b\u200bone rod, we get their required number.

Rounding the figures obtained, we obtain that the number of reinforcement n 10 \u003d 2 pcs and n 12 \u003d 1 pc.

According to technology, the installation of one reinforcing bar in a row with a width of more than 15 cm is prohibited. It turns out that with such a grillage, there should be 2 bars in a row. Thus, their total number should be 4 pieces.

Grade and composition of concrete for grillage

We will not write much about this. As a rule, at the stage of pouring concrete, everyone is interested in the question of what brand of concrete to use for the grillage and how to prepare it yourself.

We will not write much about this. As a rule, at the stage of pouring concrete, everyone is interested in the question of what brand of concrete to use for the grillage and how to prepare it yourself.

For the grillage, concrete grades M300 and M350 are used. If you prepare concrete on your own, then you can find the necessary proportions on our website in the article "Grade and composition of concrete".

It is also worth saying that when pouring concrete, it must be bayoneted, i.e. expel air that gets stuck in the thickness of the concrete.

To do this, use a special vibrator, which can be rented. You can also use a bar of reinforcement and a bayonet to expel air.

This must be done very carefully, otherwise, after solidification, in places where air voids form, the grillage will be weakened.

Grill insulation

The pile-grillage foundation, like any other, needs to be insulated. The exceptions are cottages and houses intended for living in the warm season.

A concrete grillage will serve as a cold bridge, which can negate all the insulation of the house.

The insulation scheme is quite simple and can be produced after the construction of the house. To do this, it is enough to fix an ordinary white foam plastic on the outer surface of the grillage or use a more expensive, but also better extruded polystyrene foam.

The insulation scheme is quite simple and can be produced after the construction of the house. To do this, it is enough to fix an ordinary white foam plastic on the outer surface of the grillage or use a more expensive, but also better extruded polystyrene foam.

The use of soft insulation materials such as stone wool or glass wool is undesirable. They absorb moisture well and as a result lose their thermal insulation properties. Foam plastics are devoid of such a disadvantage.

As a rule, foam plastic 5-10 cm thick is used to insulate the grillage. This is quite enough.

They fix it with special dowels, and the joints are foamed.

Many make a mistake at the installation stage - they put the foam on the ground and then fix it. The error in this case is that the foam should be at a height of 5-10 cm from the ground.

The fact is that frost heaving forces act on the ground, which raise or lower it. What kind of forces we wrote in the article (link). So, if the foam is located on the ground, then when the soil rises, it will simply be torn off the walls or it will break.

Many are afraid that if the foam is not pressed tightly to the surface of the earth, the floors of the first floor will be cold. This is wrong. In order for the floor to be warm, it is insulated. On this topic on our website there are a couple of articles "Floor on the ground."

The surface of the foam is often finished with plinth panels imitating brick laying. Extruded polystyrene foam can be plastered. But these are topics for another article. It is important to understand that the grillage must be insulated. This will save money on heating and make the temperature in the house more comfortable.

The difference between pile-grillage and strip foundations

Many people mistakenly believe that a pile foundation with a grillage and a strip foundation are one and the same. In fact, these are two completely different reasons.

The strip foundation is located directly on the ground and transfers the load from the building over the entire area.

Rostverk has a different function. It redistributes the weight of the building to the pillars, which in turn transfer the load to the ground.

An important difference is that the grillage should not come into contact with the ground, otherwise the frost heaving forces, which we talked about a little higher, can break it or pull the piles out of the ground along with it.

In the presence of unstable soils with high humidity or complex terrain, the only way out is to install pile foundations. The main advantage of such structures is the reliability of fastening even in soft soils due to the deepening of the support to a sufficiently large depth. Such devices are more reliable and durable, do not require a large consumption of concrete, but their construction is a rather laborious process.

With the correct calculation of the number of piles and the depth of their immersion, the foundation will not be exposed to moisture and freeze, therefore, in some cases, it may be preferable to tape. In places of small relief differences, when leveling the slope is unprofitable, it is possible to use a combination of conventional strip and pile foundations.

1. Types of foundations with grillage

A grillage is called the upper part of the foundation, which unites the pile heads and serves as a support for the future building. The connection of piles and grillage can be carried out by welding (in the case of using reinforced concrete structures) or by pouring concrete.

According to the installation method, the grillage is divided into:

- tape - only neighboring piles are connected;

- made in the form of a plate - each head is connected.

According to the type of materials, the grillage can be made:

- from concrete with the laying of reinforcement - piles are installed under the bearing walls, shallow trenches are dug to the depth and width of the grillage;

- suspended concrete - similar to the previous version, however, its peculiarity is that the concrete tape does not come into contact with the ground, while the compensation gap device ensures that the supports do not break when the ground oscillates;

- reinforced concrete - from a wide metal channel or I-beam, and a channel 30 is installed under the bearing walls, the remaining supports are connected by a channel 16-20;

- from wood - used less often;

- combined method - using both metal bearing elements and concrete.

2. Calculation of the distance between piles and the depth of their immersion in the pile foundation

The depth of piles is calculated based on the type and complexity of the soil. The lower part of the support should be 20-30 cm below the standard freezing depth of a certain type of soil in the region of residence. For example, the freezing depth for St. Petersburg, according to geologists, for clays and loams is 1.4 m. For the construction of the foundation, piles of at least 140 + 20 = 160 cm in size will be required. 10-20%.

To determine the required number of piles and the distance between them, SNiP No. 2.02.03-85 and GOST 27751 are used, which list the main requirements for the construction of pile foundations. The following characteristics are taken into account:

- strength of pile and grillage material;

- the bearing capacity of the soil (in this case, compaction is taken into account when installing the support);

- in the presence of significant differences in relief - the bearing capacity of the base (heel) of the support;

- degree of pile shrinkage under vertical load.

2.1. Procedure for making calculations

- To start the calculations, you need to determine the size of the total load on the future foundation, that is, find out the weight of the building. This takes into account not only the mass of the walls, but also the floor, ceilings between floors, the weight of the roof, internal and facade cladding.

- Payload (weight of furniture, household appliances and people) - if 200 kg / sq. m, then in the construction of residential buildings, 150 kg / sq. m.

- The snow load in winter is added to the resulting weight amount. The pressure of snow masses for most regions of the Russian Federation is 180 kg / sq. m.

- The sum of all three of the above loads is multiplied by a safety factor of 1.1 (in some cases a factor of 1.2 may be used).

When purchasing ready-made screw piles, one should take an interest not only in their height, but also in the ability to withstand a certain type of load. So, VSK screw supports, having a size of 86x250x2500, will have a maximum screw depth of 1700 mm, while one pile is able to withstand a load of 2000 kg. Methods for calculating the load for bored piles are more complex. Perhaps, for the calculations you will need the help of specialists. More details about the installation of concrete piles can be found in SNiP No. 2.02.03-85. A good reference book can be the book "Universal Foundation" by R.N. Yakovlev, which provides detailed calculation methods.

2.2.

Construction of a pile foundation with a monolithic grillage

An example of calculating a pile foundation with a grillage

Screw piles are used for the construction of light country houses, while in the construction of heavy cottages, more massive bored piles are used that can withstand a serious load.

In this example, for simplicity, the calculations are carried out on screw supports. It should be noted that if for such small piles the lateral friction is not taken into account in the calculations, then in the case of the construction of heavy buildings on bored piles, the lateral friction forces affecting the pile are also taken into account.

Calculation of the total number of piles and the step of their installation for a one-story house measuring 6 × 6 m:

- Determine the total weight of consumables.

Let's say the total weight of the beam, roof and cladding of the house, taking into account the snow load, will be 27526 kg.

- The payload size is 6 × 6 × 150 = 5400 kg (the payload given in paragraph 2.1 is multiplied by the length and width of the future house).

- The snow load is 180 × 6 × 6 = 6480 kg.

- Thus, the total mass of the load on the foundation will be 27526 + 5400 + 6480 = 39406 kg.

- We multiply the resulting weight by the reliability factor 39406 × 1.1 = 43346.6 kg.

- Let's say we plan to install screw supports 86x250x2500 VSK. To calculate their number, the resulting amount of the total load of 43346.6 kg should be divided by the load per pile 43346.6/2000 = 21.673. We round the resulting number to 22. Thus, to build a house measuring 6 × 6 m, we need 22 piles.

- To install 22 supports, the installation step will be 1.2 meters. For sex logs, 2 more piles should be added, which will be located inside the house.

3. Do-it-yourself foundation with a grillage

In the construction of private houses, bored machines are used only in cases where the soil is not dense enough and in order to find a denser area, it is necessary to go deep into the earth to a sufficiently large depth. If the thickness of the soft soil is large enough, it is possible to use composite piles from separate detachable sections.

In most cases, when building a private house, it is enough to install a bored pile. To do this, in the ground, a hole of the required depth is made in the ground using a garden or hand drill.

3.1. Marking and drilling of wells for piles.

After clearing and leveling the site, markings are made at the site of the future foundation: by pulling the threads, the location of the internal and external boundaries of the grillage is determined on the ground. The supports to which the stretched marking rope is attached, it is better to bring them outside the perimeter of the future foundation, so that the corners of the future foundation are formed at the intersection of the stretched threads.

Further, the place of each support is marked with reinforcement or wooden stakes. You can simply make a small hole in the place of the future pile and spill it with water: a kind of "marker". Piles must be installed at all four corners of the future foundation, and then from each corner the required distance to the next is marked, while the supports must be installed at the intersection of the walls.

Too often spaced supports will significantly increase the material costs of their construction. Their rare location can lead to significant deformation of the grillage, and then to the appearance of cracks in the bearing walls.

After the completion of the marking of future piles, the construction thread, which served as the marking of the boundaries of the future grillage, is removed from the supports, and drilling of wells for the piles is carried out.

3.2. Filling wells. Foundation pile reinforcement

Before pouring concrete, each of the wells is reinforced. The reinforcement is laid out longitudinally along the entire length of the pile. For each of the pillar supports, 4-6 rods with a diameter of 12-10 mm are sufficient. To give stability, each of the reinforcements is pre-welded together with a wire. It turns out a kind of frame (mortgage), which is inserted into the prepared well. The reinforcement must necessarily protrude above the pile - its length must be such that adhesion to the grillage is sufficient. The distance from the walls of the well (in the case of formwork installation - from the formwork walls) to the rod is at least 5 cm.

To avoid the appearance of air pockets, concreting should be carried out in layers of 25-30 cm. Each subsequent layer is tightly compacted with a spade-bayonet or a vibrator. To prevent seams at the joints, each subsequent layer is poured before the previous one dries.

3.3. Reinforcement of the pile foundation grillage

On top of each pillar, before installing the grillage, waterproofing is made of tarred roofing material. Instead of resin, it is possible to use hydrostekloizol.

Further, the marking thread is again pulled over the abandoned supports, and within the indicated boundaries, a pillow of crushed stone and sand is laid under the future grillage, which is spilled with water and compacted. To ensure that water does not go into the ground when pouring concrete, polyethylene or roofing material is laid.

The reinforcement of the grillage takes place before the installation of the formwork.

After the completion of the binding of the reinforcement, the marking thread is pulled again and the formwork is installed along it.

The pouring of a monolithic grillage is carried out in the same way as when pouring a strip foundation.

To equip a “hanging” foundation, a layer of sand is preliminarily laid under it, which is removed as the structure dries. You can replace the sand with a wooden box in the shape of the letter "P", which is installed on a layer of bricks. After 3 days, the box and bricks are removed.

Alexander Kiyaev Date: 2015-02-11

Questions and answers on the topic

No questions have been asked for the material yet, you have the opportunity to be the first to do so

Monolithic piles

Since the time of the Soviet Union, pile foundations have been used in the construction industry as an alternative to powerful volumetric reinforced concrete structures for the construction of buildings on moving soils and unstable soils. Also, the use of piles is typical for soils subject to freezing more than 1.5 meters.

In such cases, a pile foundation with a monolithic grillage is the most effective, in contrast to the tape type of foundation for construction. And also the use of this type of foundation is quite successful for all types of soil and construction conditions.

Do-it-yourself pile-grillage foundation construction technology

A monolithic grillage, applicable in this design as a connecting element, is necessary to evenly distribute the weight load of the building structure between the installed foundation piles for construction.

Concrete for pouring piles

For the manufacture of concrete for pouring monolithic piles and grillage, there are mandatory requirements, and the main one is strength. The brand of the mixture obtained must be at least M - 200 for a one-story and two-story house, and in cases of unstable soils or the expected impact of aggressive groundwater, building codes require the use of stronger concrete grades M - 250 or M - 300.

The composition of the mixture also includes pure river sand filled with crushed stone with a fraction of 20 - 40 mm. It is strictly forbidden to use bricks, residues of gypsum structures and coal burnout products as a filler.

Any qualified specialist in the construction industry will tell you which cement is best for the foundation, and what materials you need to purchase to get a first-class mixture.

Types of grillages on piles

Structurally, the piles, as already mentioned, are combined on top with a grillage, which also contributes to leveling the settlement of the piles. According to the type of materials, grillages are divided into wooden, concrete and reinforced concrete.

In modern use, wooden grillages are strapping crowns for garden houses made without making a base (colloquially, houses "on chicken legs").

Concrete grillages or pillows are used on any piles. When a solid reinforced concrete slab is supported on piles, such a cushion can be arranged with a minimum thickness sufficient to cover the heads of the piles and form a flat surface for laying out the structure.

Concrete pads do not provide reliable fastening of piles working in tension. In this case, the grillages are made of reinforced concrete, and their reinforcement is securely connected to the reinforcement of the piles.

Videos monolithic foundation on piles

Video clip describing the features and benefits of a monolithic pile foundation.

Production of a monolithic foundation

A pile foundation is a type of foundation in which the loads from a built house or cottage are transferred to the soil with the help of piles arranged using bored technology. First, a well is drilled with a diameter corresponding to the pile diameter (calculation of the bearing capacity along the pile surface), then it is reinforced with steel bars of a periodic section and then concreted with vibration to the entire depth of the pile.

The piles themselves come with a widening of the heel for frontal soil resistance (TISE technology), and without broadening, they work on friction only along the lateral surface. The vertical and horizontal loads from the structure are transferred to the pile itself with the help of a grillage, which is a monolithic concrete belt connecting all the piles together. The cross section of the grillage is selected when collecting and calculating temporary and permanent loads from walls and roofs.

It is quite easy to make a pile foundation for a frame house with your own hands. The main required structure is a field of piles, which can be made by pouring concrete into drilled wells or hammering finished reinforced concrete structures using specialized equipment.

The construction process can be divided into several stages:

In the case of the manufacture of a recessed grillage, the manufacture of a trench for pouring a monolithic structure;

A monolithic grillage is poured, as a rule, into a wooden formwork. Before starting concreting, it is necessary to pump out groundwater from the pit. The concrete mixture is laid evenly over the entire area of the grillage in horizontal layers.

Based on site materials: http://prosvai.com

The foundation is tape. How to do?

A strip foundation is a reinforced concrete structure consisting of a reinforcing cage filled with concrete. As a rule, this is ready-mixed concrete, starting from grade 250. By its appearance, the strip foundation is a closed contour in the form of a strip of reinforced concrete that runs under all the bearing walls of the building. This allows you to distribute the load along the entire perimeter of the foundation and prevent the forces of buckling of the soil and subsidence of the building.

Differences between a strip foundation and a monolithic one.

The strip foundation is the most common type of foundation in the construction of country houses and summer cottages. This is due to the fact that the strip foundation can be used for the construction of monolithic, brick, stone, concrete, frame and wooden houses and is able to carry rather big loads. If we compare between types of reinforced concrete foundations, then, in principle, there are two main types: strip foundation and monolithic foundation, which differ significantly from each other in the payload area. A monolithic foundation has a much larger working area compared to a strip foundation, which allows it to withstand heavy loads.

Pile foundation with a monolithic grillage - reinforcement of the grillage of the pile foundation of the house

At the same time, the construction of a monolithic foundation requires much more building materials and work, which significantly increases its cost. Ultimately, this determines the popularity of the strip foundation over the monolithic one.

Tape, as well as a monolithic foundation, implies the possibility of constructing a basement, or basement floor of a building. In the case when the basement is planned, the area of soil limited between the walls of the foundation is subjected to the removal of the upper layers of the soil. In the case when the basement or basement is not planned, then the soil under the house can be left.

The width of the strip foundation cannot be less than the width of the load-bearing walls of the house, and as a rule, it is usually at least 10 cm wider. To avoid transverse deformation of the foundation under the influence of soil buckling forces, the height of the strip foundation should be at least twice as wide as its width. The cross section of the strip foundation can be made in the form of a rectangle, or in the form of a trapezoid diverging towards the base. In the second case, the foundation will be more stable and durable.

Do-it-yourself strip foundation.

Reinforcement of the strip foundation is carried out by two types of reinforcement: with a variable cross section (ribbed), and smooth reinforcement. Since it is quite easy to avoid transverse deformation in a strip foundation, for this it is necessary to make the height of the foundation at least twice as large as its width, then the transverse reinforcement in the foundation frame can be used smooth. And the entire load will be borne by longitudinal reinforcement, which must be ribbed, because this type of reinforcement provides better adhesion of concrete to metal. When reinforcing a strip foundation, special attention should be paid to its corners, because they are a kind of “weak” link in this type of foundation, and the reinforcement of the corner endings must be carried out with great care.

The strip foundation, according to the method of its construction, can be monolithic or prefabricated. In the first case, this is a reinforcing cage filled with concrete mortar, in the second case, these are reinforced concrete blocks connected by cement mortar using reinforcement.

According to the depth of laying, the strip foundation, as well as monolithic, can be deep and shallow. The depth of the foundation depends on the design loads on it. For example, for a wooden or frame house, a shallow depth of laying will be sufficient, and for heavier structures, a deep one.

The basis for laying the strip foundation is building sand and granite crushed stone. Further, this sand and gravel cushion is covered with waterproofing on top to prevent the foundation from being washed away by groundwater.