Properties bronze: color, density, brand, marking, application. The proportion of bronze

The rapid development of metallurgy requires us to study the characteristics different metals And their alloys, and in this article will be considered in detail the properties of bronze and its application. In addition, let's say a few words about her species and, of course, the features of each of them.

1

This alloy is long and interesting story, because in honor of him even called one of the centuries - bronze, and he did not lose their popularity up to our times. There is an opinion that the word itself happened from the Italian consonant "Bronzo", and the latter has Persian roots. So, this is an alloy of copper with other metals, mainly tin, and their weight ratio may be different. Depending on the percentage content of the or other element, a different color of bronze is obtained - ranging from red (with a large content of copper) and ending with steel gray (in this case, no more than 35% Cu in alloy).

However, the combination of not all metals with copper is called bronze. For example, if zinc protrudes with a doping element, the resulting alloy of yellow-golden color will be the name of the brass. But if the ni and cu is fused, the Melchior is formed, from which coins minimize. This material of a beautiful silver color that saves appearance a very long time. But in this section we will focus on the views of Bronze. As already mentioned, it is basically a combination of copper with tin, such options are called tin. This is one of the first species that was mastered by man.

The greatest tin content reaches 33%, then the material has a beautiful white, a little silver color. Next, the content of this element is reduced. Changing, of course, the color, the palette is quite diverse here - from red to yellow. The hardness of such bronze exceeds the indicator for pure copper, in addition, it has the best strength characteristics, while being a more low-melting material. In this case, Tin acts as the first alloying element, besides him in the alloy there can be also arsenic, lead, zinc, but it is not at all necessary.

There are also a number of copper alloys with other metals (aluminum, iron, silicon, lead, etc.), but without the participation of SN. They also have a number of advantages, and in some parameters they even inferior to tin bronze, their palette is still characterized by a large variety. Therefore, work on the creation of color alloys is akin to creativity. Consider in the next item in more detail properties. different materialswhich we can get copper with the use of additives.

2

So, not only the color changes due to additives. In the case of tin bronze specifications Directly depend on the weight content of the main and additional alloying elements. For example, at 5% Sn, the plasticity of the alloy begins to fall, and if the number of tin reaches 20%, the mechanical properties of the material deteriorate sharply, and it becomes more fragile, the hardness decreases. In general, bronze, which includes more than 6 weight percent SN, are used in the foundry, for the forging and rolling works, they are unsuitable.

If you add to the alloy to 10% by zinc weight, it practically does not make any influence on the mechanical properties of tin bronze, only a few heares it. To improve the material being processed into it, up to 5% lead is introduced, thanks to the inclusion of which chips is facilitated. Well, phosphorus acts as a deoxidizer, and if the alloy contains more than one percent of this element, then such bronze is often called phosphorus.

Comparing tin-containing bronze with alloys, which does not include SN, the first wins the magnitude of the shrinkage, it is minimal, but the second have other benefits. Thus, the mechanical properties of aluminum bronze significantly exceed the characteristics of tin, in addition, it also has more chemical resistance. The silicincincinic is more liquid, and the beryllium is endowed with high levels of elasticity, at the same level it is also its hardness.

For spheres where bronze is used, thermal conductivity is especially important. We are accustomed that this metals for metals are quite high. But the peculiarity of all alloys is that, as a rule, thermal conductivity decreases with the introduction of additives. I did not exception and the variety of alloys we discussed. Everyone is well known how high the thermal conductivity of pure copper, often it even becomes the cause of restrictions in its use. But for bronze, everything is completely different, this quality manifests itself significantly less. Even compared to similar thermal conductivity of bronze in most cases noticeably below. The exception is only low-alloy copper alloys, naturally, they are approaching this indicator to clean metal.

Low thermal conductivity causes difficult heat removal, so bronze is not used in friction nodes, as electrodes for welding or other mechanisms where the overheating is needed as quickly as possible.

3

Bronze is widely used in different industrial areas, and its use is very different. For example, cast tin-containing alloys with high abrasion resistance are an excellent antifriction composition, and they are used as bearings. Thanks to the magnificent resistance of bronze, it is quite advisable to make fittings and, hardness and mechanical indicators of which will be quite high.

It is also worth noting that are characterized by excellent weldability, chemical resistance that prepared by the cutting tool. All these properties make this material suitable for the manufacture of responsible elements, such as membranes, springs, springing contacts, etc. Since the thermal conductivity of most bronze is small, then the parts made from such material are easily welded.

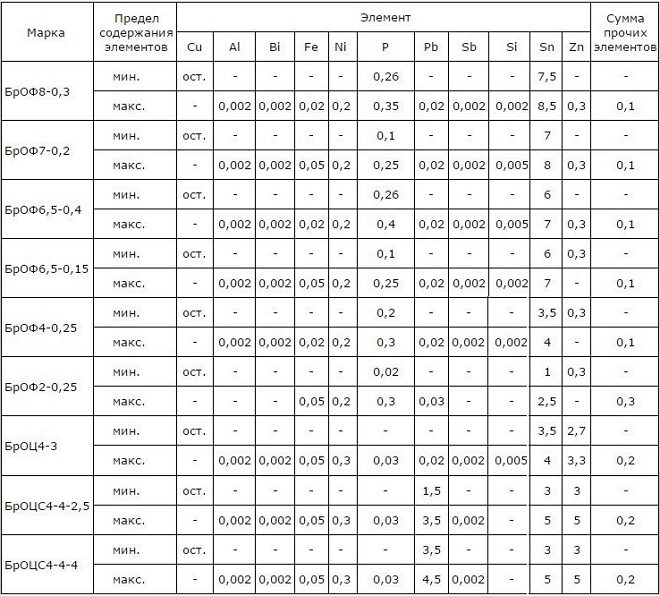

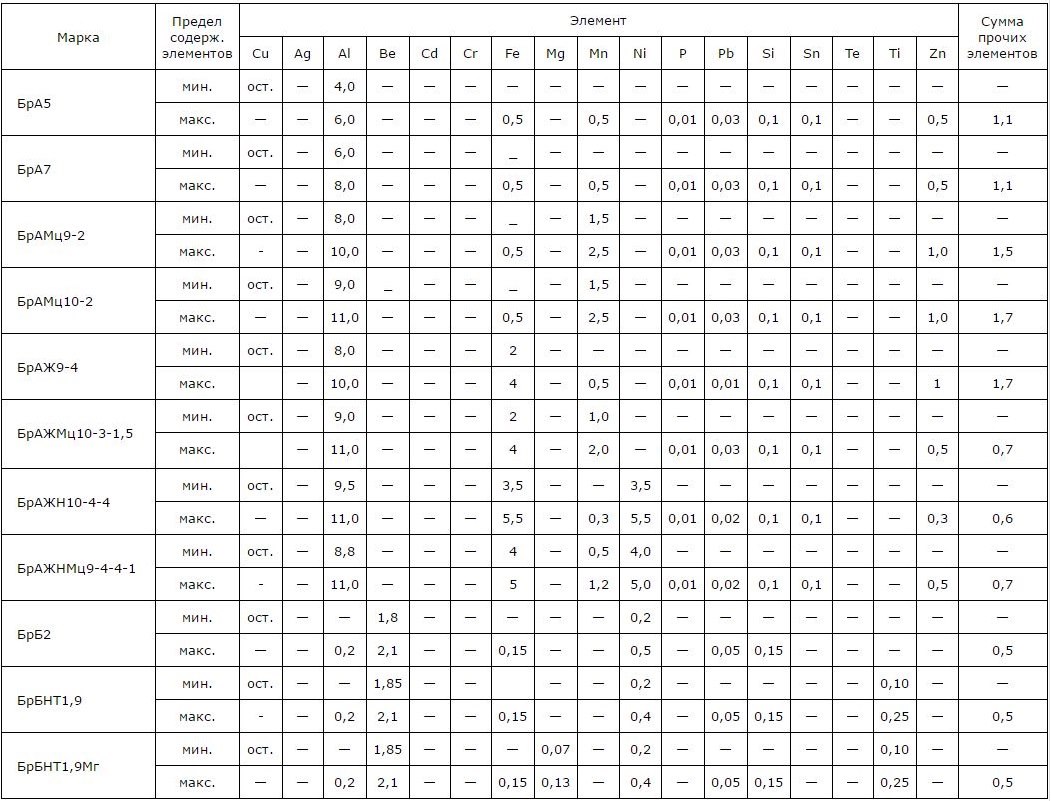

To determine the composition of the alloy, it is enough to look at its marking, which consists of a set of numbers and letters. So, the first in the designation always comes a combination of letters "BR." Then follow the designations of the weight of alloying additives in percentage content, and first the letter characters first, and numerical values, separated by a hyphen in the appropriate order. It is worth noting that the amount of copper is not specified in the bronze.

Marking is necessary not only to find out the composition of the alloy and its characteristics (hardness, thermal conductivity and others), with its help determine the proportion of any kind of bronze. To do this, you will have to use specialized directories, if the brand of alloy is unknown, then a chemical analysis should be made. By the way, the proportion of this alloy is also used in the preparation of any work. If you deepen in the formula, it can be seen that this is the ratio of the mass of the workpiece to its volume. Consequently, learning from the table share of any type of this "colorful" alloy, we can evaluate which volume will have a part of a certain mass, or, on the contrary, how much will weigh the parsing of the specified volume.

Bronze is a multicomponent or double alloy of copper and a different type of elements except zinc to improve metal properties. This type of elements that make up 2.5 percent of the total mass include alloying types. It can be: tin, lead, chrome, iron, manganese, beryllium, silicon, phosphorus, aluminum, as well as other similar elements.

Bronze marking occurs in two parameters: letters denote the alloy itself, and the numbers are the content of the components of the doping type. For example, Bra5 is a bronze of an aluminum type, and the bronze of tin type.

Bronze is one of the oldest materials in the world. In ancient times, various types of labor guns, weapons and interior items were made of it.

Bronze Specific Weight Table

Since, bronze is a complex material, calculate the proportion of bronze in the field itself is not possible. These calculations are carried out in special chemical laboratories. However, with its average share is known and is equal to the range from 8.7 to 8.9 g / cm3.

The calculation of the weight of bronze will be easier to produce thanks to the table with the values \u200b\u200bof the specific gravity and such a parameter as the weight of bronze, depending on the calculus units.

Bronze Weight Table

Classification of bronze

Bronze is classified based on two signs: technological and chemical.

According to the technological basis, bronze is divided into two types:

By chemical sign, bronze is divided into:

Properties bronze

Bronze is distinguished by high strength, resistance to corrosion, as well as excellent antifriction properties. This type of materials has increased resistance to salted water, air, acid solutions and carbon dioxide. Bronze is great for processing soldering and welding soft and solid solder.

The color of bronze depends on the type of alloying components in the composition, and can vary from white to red. Also, thanks to the latter, characteristic of the indicators are different:

Physico-chemical features bronze

Bronze - material known to humanity over the centuries. This peculiar alloy of tin and red copper was once appreciated at a level with gold and silver. In ancient times, decorations were made of this alloy different kinds Weapons and tools of labor.

Modern alloy is considered a high-tech material alloying aluminum, zinc, nickel, silicon and phosphorus, as a result of which the metal formed has various physicochemical properties. The main characteristics of the obtained alloys can be attributed:

High strength;

Good electrical conductivity;

High degree of thermal conductivity.

Methods for determining specific gravity

To determine the degree of compliance of the alloy, the planned works need to know its brand and depending on the brand you can determine the proportion and other characteristics of bronze, including to calculate the weight of any rolled out of it. All calculations are manufactured using the laws of physics and knowledge in chemistry. To carry out chemical analysis, bronze take on the sample and determine the composition of metals.

In general, the proportion can be determined and experimentally, since it is known that all the bodies of the same volume differ in different amounts of mass. In other words, the ratio of the volume and mass of the alloy is a constant value characterizing the substance under study. As the basis of the specific weight of the substance, the gravity force of this alloy taken as the basis of the volume of the substance is taken.

The ratio of the specific weight of the alloy and its density corresponds to the ratio of weight and body weight, taken as the basis of the study. To determine the specific weight of the bronze, the body made by the necessary way is first weigh in the air, and then falls into the water. According to the Archimedes, the body loses in weight and therefore tied to it the scale of the scales rises, and the load of the known weight is stacked to determine the weight of the bronze.

The value of the specific gravity can be determined by the formula.

γ \u003d p / v or specific. Weight \u003d Weight / Volume

Thus, it is possible to determine the specific weight of the concrete bronze bar with your own hands, but of course in practice, a chemical analysis of rolled products is used or simply reference data from the table if the brand is already known.

Bronze rental and examples of calculating its weight

Since when receiving bronze rolled rolled, the alloy is subjected to necessary technological processesassociated with the addition of various chemical elements that change the properties of bronze, the process of calculating the specific gravity is reinstalled in suspension from added alloying elements.

For the convenience of calculating the specific gravity of various bronze alloys, there are special calculators for calculating the specific gravity of substances and a system of table values \u200b\u200bfor specific grades, see below. Customers of metal do not need to carry out calculations independently than the choice is simplified required material For the planned type of production, but the weight of bronze can be calculated and manually, knowing the proportion of the existing brand.

Example 1: We calculate the weight of the bronze circle with a diameter of 70 mm brand Bra 9zh4 4 meters long in the amount of 18 pieces

At the beginning, calculated the cross sectional area of \u200b\u200bthe circle S \u003d πR 2 means S \u003d 3,1415 · 3.5 2 \u003d 38,465 cm 2

We calculate the mass of one bar knowing that the proportion of brand brand brand \u003d 7.6 g / cm 3

M \u003d 7.6 · 38,465 · 400 \u003d 116933.6 grams \u003d 116.933 kg

TOTAL Mass of all rolled M \u003d 116,933 · 18 \u003d 2104,80

Example 2: We calculate the weight of the bronze sheet with a thickness of 50 mm brand BRC1 with a revelation 500x1000 mm in an amount of 7 pieces

At the beginning, calculated the volume of one sheet V \u003d 5 · 50 · 100 \u003d 25000 cm 3

Therefore, with the specific weight of the brand BRH1 = 8.9 GR / cm 3

Weight of one sheet will be m \u003d 8.9 · 25000 \u003d 222500 grams \u003d 222.5 kg

TOTAL The entire party will be m \u003d 222,5 · 7 \u003d 1557.5 kg

Types of bronze in our Market Metals:

It is the properties of bronze that determine the popularity of this well-known material that is not declining for several millennia. As a result of the active development of the metallurgical industry, various brands of this alloy were developed, each of which is distinguished by its peculiarities and spheres of application.

Types of bronze alloys

The fact that Bronze was and remains and remains, says that the whole period in the history of mankind was named by the bronze age. Scientists believe that the very word "bronze" is obliged to its origin to the old name of the Italian city of Brindisi, known for its foundry workshops.

Initially, bronze was obtained in the process of melting and mixing such metals, as. The bells often cast from it, so it was called "bell". It was also used for the manufacture of weapons and workers of labor, various home utensils, sculptural compositions and interior items.

In many vintage photos, you can see the interior, which are now amazing with their beauty. With the development of the metallurgical industry, other types of bronze appeared, in which aluminum, iron, beryllium, silicon, zinc, lead, phosphorus, etc. began to introduce aluminum, iron, beryllium, silicon, zinc, lead.

The change in the traditional chemical composition of bronze allowed not only to improve its mechanical properties (hardness, strength, wear resistance and resistance to aggressive environments), but also change its color. So, the color of the surface of the bronze products may vary from red (if the bronze contains a large number of copper) to gray and even black. Changing the color of this alloy when varying its chemical composition is a very important property in the manufacture of decorative products.

Many are confused, although it is a completely different copper alloy with other properties, in the chemical composition of which, in addition to the base metal, there is zinc. Although the brass color can be confused with some brands bronze, in many of their characteristics it different materialsTherefore, their applications differ.

Another common alloy of copper, the main alloying element of which nickel is Melchior. The surface of the products is distinguished by a beautiful silver color. Melchior is actively used for chasing coins and making cutlery.

Depending on whether it is contained in bronze tin or not, it may relate to tin or uniform type.

If we talk about the bronze of the first type, then the maximum amount of tin in their chemical composition can reach up to 33%. The increase in tin content slightly reduces the proportion and density of the base metal, but increases the properties of the final material as hardness and strength. In addition, with an increase in tin in the bronze color, the color of the products that are made of it becomes lighter, which is noticeable even by their photo. In addition to tin, which also reduces the melting point of the finished alloy, in the chemical composition of such a metal may contain other chemical elements - arsenic, lead, zinc, etc.

If we talk about the uniform bronze, the proportion and density of which are slightly different from the similar characteristics of the first-type alloys, then in many of their mechanical properties they can exceed not only tin bronze, but also some steel brands. Naturally, the colors of products made from such alloys can seriously distinguish.

Thermal conductivity and other characteristics of bronze

As mentioned above, the percentage of the main alloying element in the chemical composition of bronze changes not only its color, but also mechanical properties. In this case, the density and proportion, if they compare them with similar characteristics of materials of other brands, change insignificantly. Such regularity is relevant not only for bronze, but also for brass, as well as for other copper alloys.

If we talk about the bronze of tin type, then their property, like plasticity, begins to decline if the percentage of tin in them exceeds 5%. If the tin content of tested up to 20%, then the fragility of such material will increase simultaneously with the decrease in hardness. That is why, to perform casting casting and metal processing, only that bronze can be used by the method of plastic deformation, which contains no more than 6% tin.

IN chemical composition Separate bronze marks lead zinc, the content of which can reach up to 10%. Such doping practically does not change the specific gravity and density of the metal, and also does not significantly affect its mechanical properties, but it should be cheaper.

To improve this property of bronze, like a cutting processability (in particular, to facilitate the process of breaking the chips), a slight amount of lead is introduced into it (up to 5%). Phosphorus present in some brands of bronze, which are called phosphorous, acts in them as a deoxidizer.

An important property of bronze, which contains tin, is the minimum shrinkage rate. For most other characteristics of the bronze of the uniform type are superior to tin. Thus, alloys, the main alloying element in which are aluminum, are distinguished by improved mechanical properties, as well as more resistant to even very aggressive environments. Alloys in which copper is mixed with silicon and zinc differ in high fluidity in the molten state, which predetermined the scope of their application - the manufacture of various objects by casting. Bronze with beryllium content is durable and solid materials, products of which are also distinguished by high elasticity.

When mixing copper with alloying additives, which occurs during the creation of bronze, this property of the base metal is reduced as thermal conductivity. In particular, those chemical elements that are used in the manufacture of bronze make its thermal conductivity even lower than that of another copper alloy - brass. The exception is only those brands of bronze, in which the content of copper is very significant.

Such a property of most brands of bronze, as low thermal conductivity, somewhat limits the scope of their use. Due to the fact that they are not very well removed heat, products of them are not used in highly loaded friction nodes, do not make such bronze welding electrodes, as well as elements of mechanisms that must provide operational heat dissipation.

Scope of application and labeling rules

The variety of areas is explained by her unique properties. The modern range of its brands allows you to optimally select them to solve certain technological tasks.

From bronze alloys of various brands, elements of gear, screw and worm compounds are produced, parts subjected to significant friction, electrical and sanitary products, various membranes, springs, connecting elements. In addition, bronze make cabinet parts of various equipment, it is used in the ship and automotive industry and even in the aerospace industry. Frequently from bronze made interior compositions, sculptures, now it is also used in production. furniture fittings, plumbing and various decorative items.

Only very experienced specialists are capable even by photo of the bronze product, it is made from which alloy brand it is made. And the label consisting of alphanumeric designation helps to solve such a task of non-professional. It always contains the letters "BR", which indicates that the bronze is before you. In addition, there are other letters in labeling, each of which means chemical elementwhich is part of the bronze alloy. In this case, the percentage of copper in the marking is not indicated, it can be determined if you take away from 100% (the entire volume of bronze) the total number of other elements.

The labeling of the bronze alloy, except for the details of its chemical composition, allows you to identify the basic properties with which it possesses. These properties, in particular, include the density of the material, as well as its proportion. This information is purely practical importance. Knowing the proportion that has a certain bronze alloy, it is possible to calculate the exact weight of the subject that is made of it.

All such information, as the exact chemical composition of bronze of various brands, is contained in special tables.