Original design drawings for a Horton crossbow. How to make a powerful crossbow with your own hands at home

This is a story about making a crossbow with your own hands at home. The first desire to make a crossbow myself arose unexpectedly, while watching a movie on TV. I still don’t understand what attracted me so much to this weapon. Some switch just turned in my brain, and in addition to the pure, devoted love of archery, I also developed a passionate attraction to crossbows.

By the way, I remember the name of that film: “Escape is Impossible” - a fantastic action film recorded on videotape, in the “inimitable” translation by Leonid Volodarsky. It was 1996.

The first pleasant impression of discovering such a fascinating topic as a crossbow and everything connected with it, without any intermediate stage, grew in me into uncontrollable fanaticism. I wanted to have a crossbow until I had a toothache. The same as, for example, Barnett Coomando from films with Chuck Norris.

Those who are older remember that in the 90s the arms market of our country was still in its infancy, and such an abundance of bows and crossbows as today was out of the question.

If a crossbow appeared in weapons or hunting stores in the early 90s, it was only in single copies. And even then, mostly from the category of imported cheap consumer goods, which were purchased for pennies. But they were often sold for exorbitant amounts of money by the standards of that time. And the only logical solution then was to take it and start making a crossbow for myself.

It’s worth explaining here: I was incredibly lucky that at that time I was working as a toolmaker at a local metallurgical plant. That is, from the very beginning I had access to both materials and equipment.

But that's only half the battle. The most important question was - where to get information? How can I find out how a crossbow is designed? What parts does it have inside? Where to get blueprints for a crossbow and how to assemble it later. There was no Internet yet.

As a result, I managed to find out something through questioning, thought of something myself, and somewhere I was able to read or see a picture on a topic that interested me. Information sometimes had to be collected literally from newspaper clippings.

Finally, the happy moment came, and I set about creating a prototype.

How to make a crossbow.

Visually, I was guided by a crossbow from the Snipe company. There was a company producing crossbows for some time, in St. Petersburg, I think. I cut out a photo of their crossbow from a 1992 weapons magazine. I couldn’t find information about them today, but the Interloper AK-47, which appeared much later, is suspiciously similar to that crossbow.

The guide of my crossbow consisted of two parts, connected to each other by welding (seriously, real hardcore). One of the parts was the trigger mechanism box; a bar with a milled dovetail was screwed on top. I planned to immediately install optics and did not count on open sights. The bar covered the parts of the mechanism, and a spring plate, cut from a piece of an old ruler, was attached to it, which presses the arrow to the groove on the guide.

This is almost exactly what my first homemade crossbow looked like. The only thing is that it did not have a lever cocking mechanism. And the butt did not have such elegant shapes; the lower part was straight. And it’s very similar.

I planned to make the shoulders separate and removable - before that, I had seen enough of sporting crossbows in a weapons magazine, which was brought by a fellow worker who heard about my concern.

The block for them was milled on a machine; the idea was to make it so that it would be attached to the guide with a screw, similar to how the blocks assembled with the shoulders of Excalibur crossbows are attached today. But when I was young, I made a mistake with the drill, and I had to weld the block. Only the shoulders themselves remained removable.

There’s no other word for how I fenced them off; it’s a different story altogether.

Question one: what are the shoulders made of? At that moment the answer suggested itself. And I went to where they cut scrap metal at our factory to look for a spring. What do you want me to do? I basically couldn’t find any other material for flexible elements then.

Of course, I found the spring and the work began to boil.

Making a crossbow with your own hands

I now understand that I violated all conceivable and inconceivable technical processes and principles at that time. At that moment it didn’t matter to me, I was young and full of creative energy.

I found a spring from a tractor, and used a cutter to cut a piece about 400 mm long from it. Next: it was necessary to get two narrower pieces from one piece approximately 50-55mm wide.

I couldn’t think of anything better than to use guillotine shears for cutting metal and halve the plate on them. One half turned out smooth, the other was bent with a screw. At that time I didn’t even think about some microcracks caused by rough cutting and other similar dregs.

Returning to my site, I clamped the “screw” half of the spring in a vice and straightened it using simple manipulations. In the same vice, I shaped the shoulders, bending the ends outward and slightly bending the plates. The result was two identical shoulders with a bidirectional smooth bend. Well, almost identical.

I understood that the range of bending of the crossbow arms and the operation of the springs when driving a vehicle are noticeably different, and the halves of the arms would have to be re-heated. Fortunately, our workshop had a well-equipped thermal unit with a competent thermal operator. It was he who told me how to properly harden spring steel.

Looking ahead, I will say that soon, repeating the same technology, I had to make a second set of shoulders. This happened because two young dunces - me and my friend - decided to set the bowstring by resting one shoulder on the bench and pressing the other from above. A lever was created that went to a break and the lower arm broke near the fastening screw.

I made the second set of shoulders faster, taking into account previous experience. In terms of tension force, the arms turned out to be somewhere around 60-65 kg, with a working stroke of the bowstring of 250 mm. The shoulder width was 720mm.

The small working stroke is due to the peculiarity of the steel arms, which do not have the same flexibility as fiberglass ones with similar dimensions. But I didn’t want to make a wide arc for the sake of a slight increase in the stroke of the bowstring.

On top of the steel guide I glued a fiberglass plate with a semicircular groove along which the bowstring was supposed to slide and the bolt to move. I didn’t take into account at all then that the fact that the bowstring lay on the guide with a large bend. The friction turned out to be quite strong and soon the fiberglass began to wear out, bristling with fibers.

The bracket on which you place your foot to cock the crossbow turned out to be a little small and only allowed you to insert the toe of your boot. But over time I got used to doing it.

The steel parts of the crossbow were finished, the next step was making the stock. The only wood suitable for this task was oak, ash and birch. The choice fell on ash. It had a nicer texture than just white birch wood. The oak was simply too heavy.

Folk art of homemade crossbowmen

The butt and fore-end were supposed to be separate. I made the forend in the shape of a strongly elongated trapezoid, the wider part was located just under the palm, then it smoothly tapered in width and height. The edge of the forend was beveled to give it a more graceful shape.

The stock looks wide, with a straight bottom and a large hole where the thumb goes through. It was comfortable to hold the crossbow and aim. The handguard was attached in a rather funny way: a groove was milled into the wood, into which the guide almost completely sunk. Without further ado, I took and glued the forend and a plate with a groove directly to the guide using epoxy - for some reason I didn’t want there to be holes in the lower part of the forend and screw heads visible. It seemed that it would be unaesthetic.

After all the metal parts were assembled, the forend was glued and the stock was installed - it was attached with two screws to the sight post from below, another question arose: “Where can I get suitable threads for the bowstring?” I immediately rejected all the advice to use nylon thread or, as some “especially gifted” people said, fishing line.

My stepfather helped me out, quite by accident. He was sorting out old trash in the garage, and from somewhere he fished out a large coil of thin rope, twisted from unknown threads. The rope did not stretch under the force, and after several experiments I wound a bowstring from it onto a crossbow.

There are also block homemade structures

I almost forgot to tell you how the trigger mechanism on that crossbow was designed. It turned out, oddly enough, for me it was durable, reliable in operation and consisting of only three parts and two springs.

The hook that secures the bowstring in the cocked state, or popularly “nut,” was made in the form of a washer 10 mm thick. The groove for the passage of the bowstring and the protrusion into which the locking sear fits are made using files of different calibers. The “nut” was single-toothed and the back of the bolt did not rest against the bowstring.

Wanting to squeeze the trigger mechanism into the small dimensions of its box, I got carried away and slightly incorrectly distributed the length of the sear arms relative to the center of rotation of its axis. This played a cruel joke on me and the descent turned out to be a little harsh.

During the firing process, the “nut” rotated, carried away by the bowstring. After which he hit the front wall of the box and happily bounced back, where he stopped. Before cocking, it had to be lowered manually each time to allow the string to pass through and the “nut” to be rotated to the position where it was fixed by the sear. I was unable to find a technical solution so that the hook would remain in the lowered position after the shot. I racked my brain and racked my brain, but couldn’t come up with anything worthwhile. After which I gave up on this matter and left everything as it was.

The final touch in creating this crossbow was the installation of a sight. At that time, gun stores began to actively import pneumatics and various useful things for them. Like inexpensive optical sights, for example. This is the one I bought. I took a simple four-power scope with an eyepiece with a diameter of 25mm. Soon it was installed on the crossbow.

The long-awaited moment of the first tests was getting closer, all that remained was to make the bolts - and you could shoot.

Crossbow at home: preparing for shooting.

It was impossible to find aluminum tubes with a thin wall and I had to opt for wooden shafts. For this matter, I again turned to the place where they fitted me with wood for the butt - to the Model Shop. The same ash tree came up, whose dense, but not very heavy wood was suitable as well as possible.

A friend of mine turned the shafts on a wood lathe; the conical tips also came out from under the turner’s cutter, only for metal.

I painted the bolts poisonous red to make them harder to lose, and I also coated them with varnish on top. The tips, which were sharpened for me as many as ten of them, turned out to be of slightly different shapes, but almost the same length - and that’s a joy. I started going through them and ended up selecting more or less the same ones. It turned out to be two groups of tips, six in one and four in the other.

I placed the tips on the shafts, securing them with Moment glue. Next in line was the plumage, which was not clear what to make of. A bookstore helped me out - there I saw and later bought these thin multi-colored folders into which pieces of paper were inserted. Their covers were made of thick cellophane, which held its shape well. So they were used to feather the bolts for my crossbow.

I invented the manufacturing technology quite quickly: I cut out a pen template from cardboard, traced it with a pen, attached it to the covers of folders, and used ordinary scissors to cut them into the required quantity.

As you probably know, branded feathers for bow and crossbow arrows have a seat in the form of edges facing to the sides, by which the feather is glued to the arrow shaft.

I got around this point in a rather interesting way. To begin with, I cut the feathers in a double set. One thicker feather was glued together from two thin halves. Before gluing, I outlined the edges of the halves identically, and then simply bent them in different directions. The resulting seats are almost the same as those of factory rubber feathers. All that remains is to glue them onto the bolt shafts, which is exactly what I did. There were two feathers on each bolt, because there was a semicircular groove on the top of the guide. I was not yet technically mature enough to make a deep groove along which the lower feather passes, when there are three of them.

So, tests! Everything happened in the forest, the target was a cardboard box filled with old rags and leaning against a thick pine tree. With my first shot, I drove the bolt into the tree just below the box. An attempt to pull it out ended with the shaft remaining in my hand, and the tip stuck deep in the trunk. I didn’t bother picking at the tree to get it out and left everything as it was.

The crossbow showed its good side, it shot sharply, the steel shoulders straightened at a good speed, sending bolts into the target. The lock worked properly, without breakdowns or interruptions, except that the release was a little harsh. I cocked the string while wearing gloves - it cut my fingers very “spiritually”, but I didn’t know anything about the tension cord and how it works.

As a result, after the first shooting I only had three intact bolts that were not broken.

That crossbow stayed with me for some time, pleasing the eye and warming the soul. But I moved on, working on the creation of the next, more perfect model, and it was given into the possession of my friend, who then shared my passion.

You will learn about how my next homemade products turned out in another article. In the meantime, here is an example of an interesting video of a crossbow made at home by the same enthusiasts.

Video of shooting from a crossbow made by yourself.

This article will be devoted to such throwing weapons as a homemade crossbow. From the following lines you will not learn how to make a crossbow yourself, but you will gain information about what kind of homemade crossbows there are and how well they shoot. Also, within the framework of this article, we will touch upon the issue of the legality and appropriateness of such a hobby.

This article will be devoted to such throwing weapons as a homemade crossbow. From the following lines you will not learn how to make a crossbow yourself, but you will gain information about what kind of homemade crossbows there are and how well they shoot. Also, within the framework of this article, we will touch upon the issue of the legality and appropriateness of such a hobby.

The material will be of a critical nature and we will try to dissuade you from such a dubious undertaking as making a crossbow at home. Let's get started, I hope you find it interesting.

Archery market in Russia is growing year by year. There are more and more lovers of silent and accurate shooting in the country, and what could be better suited for this activity than a crossbow? Perhaps a compound bow, but to shoot accurately with a bow you need skill and some experience.

With a crossbow everything is somewhat simpler. The form factor of a rifle with a shoulder rest, the ability to install optics or a collimator make shooting from this type of weapon more familiar, and, therefore, more popular among consumers.

There are not many brands in the world that produce high-quality and reliable crossbows. You can count a dozen companies, and almost all of these manufacturers are presented on our website. But in general, manufacturers satisfy the demand of almost all categories of consumers. The price of a crossbow starts from 5,000 rubles; the natural question is: who and why in such a situation should make a crossbow on their own, if you can simply buy it in a store.

As a rule, this kind of crafts is carried out by very young people under 20 years old, or experienced men who are interested in designing, and very often designing everything. Very rarely, almost never, a person who is sorry for the money to buy a crossbow starts making a homemade crossbow.

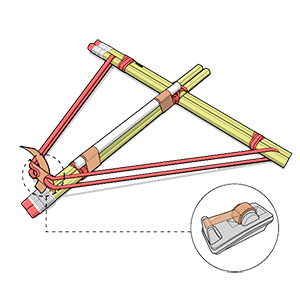

In fact, despite the deceptive simplicity of the design, making a crossbow yourself is not as easy as it seems. Most often, homemade crossbows are made from bows or spring-like steel plates with blocks. Kulibin uses a metal cable as a bowstring. Such bulky things shoot poorly, they weigh a lot, and they hit crookedly.

If we talk about blocks for a homemade crossbow, then, as a rule, they are either machined independently, or, in some cases, aluminum reels from old tape recorders are used. The wear of such eccentrics is extremely high and they fly even from a normal shot, not to mention a blank

The bed of a homemade crossbow can be either steel or wood. It all depends on the imagination of the particular “Kulibin”. The triggers are made using mechanisms from old guns, or everything is made independently on milling machines. A popular game among DIYers is making a compound crossbow from a recurve one.

As a spoonful of honey, let's say that sometimes very impressive gizmos are obtained, of impressive size and impressive power. The main problem with homemade crossbows is the accuracy of hits, which cannot be compared with branded models. On various forums you can see photographs of homemade crossbows with a brief description of the technical characteristics. And among the mass of slag you can find models with a tension force of 40 kg. and a firing range of about 100 meters. But here’s the catch - the ballistics of homemade crossbows, as a rule, are poor and it’s practically impossible to hit anything even from 50 meters, let alone 100.

So that you understand, before being released into production, branded models are carefully tested and shot at various types of targets, and all detected deficiencies are corrected. Then, already modernized and free of defects from the last test, the crossbow is tested again. And so on until the declared range and shooting accuracy are achieved. Need I say that in the case of “homemade” ones, all this does not exist?

Another disadvantage is the legality of such a hobby. If you overdo it with increased tension, you can get an impressive administrative fine, provided that the product is found in your possession by the police. However, the police will be obliged to confiscate such a contraption from you, even if the tension gain does not exceed 40 kg, because you will not have certificates for the product.

If you want to make a crossbow yourself, we strongly recommend that you think carefully before getting started. This activity, although interesting, is labor-intensive, and the result is completely unpredictable. At the exit you can get either a deadly bazooka or zilch.

However, remember that it is difficult to call this activity legal. In the best case, the product will be confiscated from you, in the worst case, you will also pay for it. This opinion is a purely personal point of view of the author of the article and may not coincide with yours. In our opinion, it is much simpler, smarter and more convenient to buy a crossbow in an online store.

In this case, you will receive guaranteed results, declared technical characteristics and a full package of documents including certificates stating that this product is not a weapon.

Now it has become fashionable to hunt with a bow and crossbow. Although this is prohibited in our country, you can still shoot at targets by practicing this difficult task. You can make a crossbow with your own hands at home for training. After all, good models from well-known companies are very expensive. Or it can be made “for yourself”. It is worth remembering that if the weapon has a tension of more than 20 kg, then it is considered a cold weapon. Therefore, when creating a crossbow, it is worth considering this important nuance.

There are classic models, they look like ancient ones, and their design is simple. There are also modern crossbows, they are called "block" crossbows. Such weapons have a more complex design due to blocks and other innovations that enhance their power. It will be much more difficult to make such a crossbow at home, but the description of this process and the drawings, which will be detailed in the article, will help you with this.

The crossbow has many components:

some modern models have blocks at the ends of the bow.

trigger mechanism;

What to make a crossbow from

The main material from which a crossbow is made is wood. The stock and bow are made from it. The trigger mechanism in powerful samples is machined from iron. And those in which the tension force is less than 20 kg can be made of hard wood, it will withstand it quite well. Spring metal and various composites are also used for bows.

Regular crossbow made of wood

First, let's look at how easy it is to make a crossbow with your own hands, and let's start with its simple shape. This is a standard design for ancient weapons, and it can be used not only for shooting, but also as a spectacular piece of furniture when hung on the wall.

What wood to use

To create a crossbow you need to choose:

All of these rocks are dense enough to withstand the enormous stress that will be placed on the bow and crossbow stock.

Preparation of material

In order for a weapon to fire long and powerfully, its material must be properly dried for a year. Having cut the required trunk or branch, both cuts must be painted over. To do this, you can use any glue, paint or varnish. If you close the cuts in this way, moisture will not be able to quickly leave the workpiece, so the wood will dry more slowly and evenly. This way, internal cracks do not form in the material, and a crossbow made with your own hands at home will serve for a very long time.

After this, the log is placed in a dry place where the sun's rays will not fall on it. It should remain like this for a year. After time, the bark is removed from the workpiece, so it dries for another week. The log is then sawn in half. It sits like that for another week, only after that you can start creating a crossbow.

Tools for making a crossbow

Sandpaper of different grits.

Carpenter's cutter.

Chisel.

Making a bow

On the workpiece, choose the side in which the annual rings of the tree are thinner. This is the north side, the fibers on it are denser than in other parts. This is what we will use when creating a crossbow with our own hands at home. From this part you need to make a bow.

Mark the middle, put about two centimeters on both sides of it, marking the part that will be clamped in the crossbow stock. This will be the thickest part of the onion. They begin to cut the material from it, gradually moving towards the edges. They chip the workpiece gradually on both sides, checking until it begins to bend at least a little.

After this, you need to take a strong rope and make loops at its ends. This will be a test string. It is necessary to check the bow tension. It is very important that his shoulders bend evenly. By putting on an improvised bowstring and drawing the bow, you can see where to remove the material. They are marked and carefully cut with a knife. This must be continued until the product begins to bend evenly on both sides.

Knot processing

Very often there are knots on the material: some are visible immediately, others can open during the processing of the material. What makes them dangerous is that they can cause chips. Therefore, you need to treat such places with a well-sharpened knife. If you don't have confidence or experience, it's better to tinker a little longer and sand them down with sandpaper. You can also use a file for this purpose.

Bed

When the bow is ready, put it aside and begin making the stock. To begin with, they choose where there will be a groove through which the arrow will fly out, and make this place perfectly level. It will depend on him how accurately the crossbow will shoot. To understand everything, it is better to look at the drawing of the crossbow. How to make its stock is shown in detail here. After this, the gutter is cut to the required length. Usually it is about 30 cm. Then a recess is made for the bow and trigger mechanism. They are convenient to cut with a chisel and a carpenter's knife.

Trigger

As mentioned above, it can be made of dense wood or, if the crossbow is powerful, of metal. The most is the so-called “nut”. It consists of a cylinder, where on one side there is a hook for the bowstring, and on the other there is a stop for the trigger. In high-power crossbows, the trigger is more refined for an easier trigger pull when loaded.

We looked at it in detail, the Master class with drawings, we hope, will help you understand all the intricacies.

This is a common medieval model. Now we’ll find out how to make the same weapon, only a modern model.

Compound crossbow

Such a device is much more difficult to make; it will require many more tools than a regular one. So, we create a crossbow with our own hands at home from fiberglass. This material is ideal for making bows because it is tough and yet lightweight. It can be cut from a single piece of fiberglass 1 cm thick or you can make it yourself. If you’re not too lazy to tinker, it’s better to make it yourself.

Making fiberglass shoulders for a crossbow

You need to take fiberglass or Kevlar and cut it into strips. You need from 30 to 40 of them. In general, it is better to try everything experimentally. These strips are glued with epoxy resin so that everything becomes monolithic when it hardens. You also need to think about how to put this entire “sandwich” under the press. It is best to use boards, place the shoulders between them, and clamp everything with clamps.

There should be less thickener than usual, ranging from 8 to 10%. Everything hardens within 24 hours, but if the room is cold, the time may increase. When everything has hardened, the shoulders are finalized by cutting off the protruding edges with a knife and sanding with sandpaper.

Now we will look in detail at how to make a crossbow with your own hands at home and what additional elements of its design need to be made.

Making a figured bed

To do this, you need to take a board at least 4 cm thick. Mark where the butt, handle, trigger mechanism and mounts for the arms of the bow will be. In general, everything is according to the drawings. After this, you need to drill all the necessary holes and cut them out.

Blocks

They can be made from aluminum. It would be better if they were on bearings. The middle parts of roller skate wheels are perfect. They are strong enough to withstand heavy loads and are the perfect size. The axles for them need to be 5 mm thick. You can take them from rollers or make them yourself.

The fasteners are made of sheet steel or similar durable material. You can also make the ends of the bow arms thicker before pouring epoxy resin to install the blocks, in which case fastenings will not be needed.

After this, you need to install a trigger mechanism with a trigger and an arrow holder on the crossbow you made yourself at home. In general, all parts are connected with bolts; washers are always used. They will allow you to twist everything more tightly without damaging the material.

In compound crossbows, the bowstring is longer and is tensioned differently. It seems to cross, and when drawn, this system allows the arrow to give twice as much energy to flight as in the case of a conventional crossbow with the same bow.

In powerful block models, the bowstring is the only one capable of withstanding the enormous sharp pressure of a shot. In crossbows whose power is no more than 40-50 kg, it can be woven from nylon threads.

Making a bowstring for a crossbow

Using the described method, you can make a bowstring for both a recurve and a classic crossbow. It’s just that their length will be different due to the design features of both models.

They take a board the length of the planned bowstring, drive in two pegs, on which they are wound in a circle. When the thickness of this long oval becomes 5 mm, it is wound, making a gap of 2-3 mm between the turns. Near the pegs you need to braid without gaps, because there will be loops for hooking.

Regarding the bowstring, one can also say that if you make it too thick, the strength of the crossbow is reduced. However, thin ones can tear. So in this case you need to choose an intermediate thickness. It is better to study similar sports models with the same tension and make a bowstring of their thickness. When this is done, the two halves are joined and wrapped together. Again, special care is needed near the hinges. Then they wrap the middle where the string will catch and push the arrow. This place is also done carefully, because it will be subject to a tremendous frictional force. All cut edges of the threads must be coated with glue. This will make them denser and more monolithic.

This article presents drawings and a description of how to make a real crossbow at home. It's not that difficult, especially if you're making wooden weapons. If the product is manufactured for hunting in order to achieve enormous power, then you should choose a block model. Its design is a little more complicated; you may need a machine to make some parts.

Just twenty years ago, a bow or crossbow for individual use did not exist in nature. Some eccentrics and fanatics of historical reconstructions took on making them at their own peril and risk, having absolutely no idea what they would get in the end. And all because the process of accumulating experience and honing skills in the manufacture and use of throwing weapons, which lasted several tens of thousands of years, in our time was once interrupted and anathematized.

Now all this rare knowledge has been taken out of dusty chests, they have learned to make bows and crossbows using modern technologies, and the army of followers of William Tell and Robin Hood is growing at an exponential rate. And today we have prepared drawings and diagrams for you that will tell you how to make a crossbow at home.

Despite the abundance of online stores selling throwing weapons, as well as a fantastic range of products, there are many who want to make a crossbow on their own. Most of them don't know where to start. Today we will tell you about the main design features of the crossbow. This knowledge will help you avoid manufacturing errors, as well as frustration and injury when using it.

Before starting work, there are two main points to know.

- In our country, a crossbow is recreational and sporting weapons. Hunting with it is prohibited. Any throwing weapon with a tension force of more than 43 kilograms is considered a combat weapon, the right to use which is given by the licensing authorities of the Ministry of Internal Affairs.

- Crossbow is a structure that experiences enormous loads during operation. Therefore, any carelessness in its manufacture will most likely lead to injury. Any part of it must have a multiple safety margin.

So, let's learn how to make a simple crossbow at home.

The video below will tell you how to make a crossbow at home:

Onion

The crossbow's energy source is the bow - an elastic plate of complex shape, having one main bend and, as an option, two additional ones at the ends. You need to start making a crossbow with this particular part and adjust everything else to it - choosing the type of tension (recurve or block), the size of the stock, the type of trigger.

Wood and composite

The urgent question is what to use as a material for the bow: wood, composite or metal?

- Tree- the worst choice. Available “pieces of wood” lying underfoot are garbage, suitable only for lighting stoves. Branches cut down in the forest lose their elasticity as they dry, crack and fall apart. From this material you can only make something for short-term entertainment in the country. Of the models sold in stores that contain wood, the one that is very popular is also the one.

- Composite, created from fiberglass and epoxy, is very tempting and simple in appearance. But there is an obstacle - the need to scrupulously adhere to the technology of all work. Mix proportions, drying, aging. At home this is almost impossible.

Metal

There is only one option left - metal. If you have an old Moskvich with a set of leaf springs on hand, consider yourself lucky. One sheet is taken from the entire package - the second. If you are not too scared by the dimensions, then the first one will do. Moreover, it has tubes at the ends - an almost ready-made bracket for attaching blocks or bowstrings.

A block is used to attach the bow to the stock. This is a U-shaped design that wraps around the stock from the front. It can be welded tightly to the spring leaf, but in this case, when the bow is bent, the welds will experience excessive pull-out stress. Therefore, it is better to attach the ball joint from the VAZ 2108 to the block. The bow is attached to its pin. This is also convenient because there is a hole on the spring leaf.

If you are very strong, then you can choose the recursive method of tensioning the bowstring (as in, etc.). But it’s better to choose a block one (as in models, etc.). To attach the blocks to the bow, if you have chosen a second spring leaf, you need to attach brackets to its ends. A bolted (or even better, rivet) connection is preferable to welding, since this unit experiences strong vibration loads. As pulleys, use parts of the window lifting mechanism of the same Moskvich.

Regarding the bowstring, an obvious solution arises: a thin metal cable. But it is not entirely correct, since steel cables do not withstand variable loads well. It is better to choose a climbing cord with a diameter of 5-8 mm.

Once you've made your bow and attached the string to it, you can conduct full-scale bending tests. It’s great if you have a dynamometer of 100-150 kilograms. As a result, you will learn two parameters necessary for further work: the length of the bowstring stroke and the load.

Read below to learn how to make a stock for a powerful crossbow at home.

Lodge

For this part of a homemade crossbow, wood is the only option. But not everything. In any case, not aspen, alder, spruce or pine. Better beech, elm, oak. The product has been dried for twenty years. It is clear that you will never find something like this anywhere. Therefore, use moisture-resistant plywood with a thickness of 7-9 mm. 3 or 5 contours of the stock are cut out of it, and then this package is glued together with epoxy resin. Not very pretty, but extremely reliable.

- Regarding the shape, give up the semi-pistol style and use a straight English stock. It is not only easier to manufacture, but also stronger.

- When assembling the stock package, it is necessary to take into account both the course of the bowstring and the load. The first determines the distance from the block to the slot for the trigger mechanism. The second is the thickness of the stock walls at the place of its attachment. It is the straight English stock that will allow you to avoid excessive thinning when moving from the forearm to the butt.

- The most important part of a crossbow stock is the arrow guide. It should be smooth and durable. For it, you can use the plates framing the side windows of the Moskvich, furniture fittings, and other similar-shaped parts.

- If you use a block type of bowstring tension, then there should be a groove in the forend under the guide for the cable system. This is another element that weakens the stock, so give up the idea of making the forend dainty. High will protect your fingers from getting caught under the bowstring and traumatic amputation of the phalanges.

Typically crossbows have a plastic stock, such as models and others.

Below we will tell you how to make a homemade trigger mechanism for a crossbow at home.

This video will tell you how to make a crossbow from wood (plywood) with your own hands:

Trigger

If you are not a sixth-class mechanic, then give up the idea of making this element yourself. Make an effort and find the trigger for any spring-piston air rifle. In the most difficult case, you will only have to modify its tooth that holds the piston - it may be too small for a thick bowstring.

A casing with a height of 2 to 5 cm is placed above the trigger mechanism, which is necessary to protect it from moisture and dirt, and also serves as the basis for sighting devices - rails for optics or rear sights. Weaver, Picatinny or dovetail rails can be purchased at any online store that sells pneumatics.

The front part of the casing above the trigger mechanism is made in the form of a long (no more than 10 cm) elastic “tail”, which holds the back of the arrow on the guide.

Making arrows

Canonically correct crossbow ammunition is called a “bolt”. But many online stores sell crossbow arrows. For crossbows with a rifle stock, lengths of 14, 16, 20, 22 inches are suitable. To be completely honest, you won't find better magazine arrows. Unfortunately, none of them are worth less than 150 rubles. Therefore, it is worth trying to make them yourself.

Canonically correct crossbow ammunition is called a “bolt”. But many online stores sell crossbow arrows. For crossbows with a rifle stock, lengths of 14, 16, 20, 22 inches are suitable. To be completely honest, you won't find better magazine arrows. Unfortunately, none of them are worth less than 150 rubles. Therefore, it is worth trying to make them yourself.

They can be made from straight-layer wood without knots. As an option, use furniture parts - balusters from chairs, railings of cribs. Good arrows are made from aluminum tubes with a diameter of up to 2 cm. If desired, you can even use electrodes of the maximum diameter, but they bend hopelessly when hit and it is difficult to attach the feathers to them.

Thin plastic is used for the plumage. Natural bird feathers can give the unexpected effect of chaotic changes in flight direction, since they have natural curves that must be taken into account.

The main condition for a good, smooth flight is balancing. The center of gravity of a crossbow bolt should be after the first third of its length from the tip. If it is not metal, the end of the arrow can be loaded with lead wire wrapped around the shaft.

The issue of equipping an arrow with a tip must be treated without fanaticism. Sharpening metal on lathes, milling and polishing, giving it exquisite shapes - these operations are accessible to few. In addition, such a tip is extremely dangerous. If you do not need to pierce knight's armor, then a wooden bolt can simply be sharpened at an angle of 30 degrees using a regular knife.

We will tell you further how to make a crossbow that shoots with your own hands from paper, pencils and other materials.

Cool shooting games

Shooting with toothpicks or matches can be made from a wooden clothespin. To do this, disassemble it and remake it:

- widen the narrow groove for the spring of one half to 1 cm, make the same on the second, but with an indentation of 1 cm;

- at the front ends of both halves, on the side of the narrow grooves for the spring, make a longitudinal groove 1-2 mm deep;

- assemble the clothespin halves “inside out” by twisting them with thread;

- install the clothespin spring with its paws in the cut grooves, and with the spiral outward;

- place a toothpick in the hole between the halves;

- press the spring spiral, moving it into the semicircular cutout;

The spring tab will slide along the long slot, clicking on the toothpick and causing it to fly out.

To learn how to make a mini crossbow from pencils with your own hands at home, watch the video below.

MODERN CROSSBOWS - BASICS, TERMINOLOGY, CLASSIFICATION

Part 1

The popularity of this weapon is growing, more and more people want to touch this wonderful example of human progress. After all, humanity has always strived to hit targets faster, more accurately, and from a greater distance. Some want to touch their childhood dream, some hunt, some want to make a crossbow with their own hands, and some just like to shoot at a target. Most newcomers to the crossbow business have many questions about which crossbow to buy or make, what a “block”, “guide”, “shako”, “cable” is, how a “block” differs from a “classic” and many other questions.

Indeed, the former powerful throwing weapon of ancient armies is experiencing a kind of “Renaissance” in our time, now it is available to almost everyone. Any citizen who has reached the age of 18 and has a passport can purchase a crossbow with an arc force of up to 43 kg, which has an appropriate certificate. Naturally, there are also restrictions - in our country, crossbows with a tension force of over 43 kg are considered weapons, and hunting with them is prohibited. That is, even if you have a hunting license, it’s not your destiny to hunt with a crossbow. Perhaps, after some time, something in this regard will change in our legislation, and the hunter will be able to feel what it is like to be one on one with a powerful beast, when one arrow is loaded and there is no room for error, since reloading a crossbow, even with a cocking lever, takes quite a long time. Naturally, the hunter with a crossbow bears more responsibility, since there is no opportunity to fire a second shot and finish off the wounded animal. The shot must be fired from a short distance and certainly in an area incompatible with the life of the animal.

The point of this article is not to tell where and how the crossbow (crossbow) came from, but to explain what parts a crossbow consists of, what types of crossbows there are, what accessories are used for them, types of ammunition, tensioning devices, etc.

1. Main parts of the crossbow and basic terms

A modern crossbow, of course, in its operating principle (the release of a projectile being thrown by a bowstring held by a trigger mechanism, through a trigger lever (hook), due to the stored energy of an elastic element (arc, shoulders) located across the bed) is no different from its older brother, however The design has undergone quite significant changes.

First, let's look at the main parts of the crossbow using the example of a device with the so-called “classical” layout (Fig. 1). The most noticeable difference between it and the usual old crossbow design will be the presence of separate arms instead of a solid arc. But since the vast majority of modern crossbows have such separate arms, they are actually the “classics” of our time.

Fig.1. Main parts of a crossbow.

Fig.2. Crossbow with a single guide stock

All parts of the crossbow are mounted on a single profile - a guide. There are crossbows in which all the parts are attached directly to the stock and there is no such part as such. In this case, the guide is the groove in which the arrow is placed. An example of such a crossbow is shown in Fig. 2. Please note - the crossbow shown in the last picture also has simpler - straight shoulders. The guide should not have any bends or curvature, because in essence it is the “barrel” of the crossbow. You yourself understand what shooting from a weapon with a crooked muzzle will be like. The guide, in the part along which the bowstring and arrow will move, is polished for better sliding of the projectile and less wear on the winding of the bowstring. Also, additionally use lubricant. The bowstring is rubbed with wax (beeswax or special wax for bowstrings).

As mentioned above, in most modern crossbows the arc is made split, that is, in fact we have two separate arms. Firstly, it allows the arms to be raised so that they are level with the top edge of the guide without tilting, which reduces friction between the string and the guide; secondly, it allows the shoulders to be positioned more parallel to the guide; and thirdly, for ease of transportation. It is very important that both shoulders have the same characteristics in terms of geometric parameters and physical properties.

The arms are attached to the guide or directly to the stock using a block - this part, which carries a serious load, is subject to fairly stringent requirements for strength and geometry. After all, the synchronization of the work of the shoulders will depend on the accuracy of its manufacture, and the reliability and health of the shooter will depend on its strength. In general, in a crossbow, for proper operation and accurate shooting, the accuracy of the manufacturing of the mechanisms must be at a fairly high level.

Fig.3. Crossbow-pistol with a separate superstructure over the castle

The bowstring is an important and very important part of the crossbow. It must meet several requirements - be strong, light, flexible, not stretch, and hold a tug well. Mostly, modern crossbows have a bowstring made of synthetic fiber Dyneema. Fishing braid is also made from the same fibers, which, due to its wide selection and availability, is one of the best materials for weaving a bowstring yourself. On the bowstring, in places of friction against the guide and on the loops thrown over the ends of the arms, a winding is made, for example, from nylon thread. Such a winding is rewound as it wears out - this mainly concerns the warhead, where the bowstring wears out the most.

A trigger mechanism (SM), which is also called a lock, is mounted in the rear part of the guide. This mechanism keeps the bowstring cocked and allows it to be easily released when the trigger (lever) is pulled. It can be assembled directly into the guide or have a separate housing mounted into it. If the guide, as a separate part, is missing, then the lock cuts directly into the stock. The body of an SM crossbow in the upper part usually has a superstructure on which sighting devices or rails, such as a dovetail, Weaver or Picatinny rail, are mounted, for all kinds of optical or collimator sights. Also attached to the superstructure is an arrow clamp, which is a leaf spring that keeps the arrow from falling out in a loaded crossbow. On some crossbows, the superstructure is not part of the lock, but is attached as a separate part to the crossbow above the SM (Fig. 3). There are add-ons that can be adjusted - they change the angle of inclination, which makes it possible to adapt the crossbow sights to longer distances, because the flight of an arrow in terms of flatness (straightness) is much inferior to that of a firearm. Although, in my humble opinion, this does not make much sense, since the speed of the arrow drops quite strongly with distance, and the time it takes for it to fly, for example, 200 m, is quite long. Naturally, the lethality at such a distance is low.

Fig.4. Assembling the main parts of the crossbow

A little about the crossbow stock. In principle, there are no big differences from firearm stocks. The only thing is, due to the superstructure and highly raised sights, the butt line is located higher. The guide assembly with the remaining parts of the crossbow is attached to the stock or, as mentioned above, all parts of the crossbow are mounted on the stock itself. An example of assembling the main parts of a crossbow is shown in Fig. 4.

2. Classification of crossbows

According to state standards of the Russian Federation [Change No. 1 GOST R 51905-2002 Sports crossbows, crossbows for recreation and entertainment and shells for them. Technical requirements and safety test methods], crossbows are usually divided into:

universal sport-hunting and match crossbows, which are throwing weapons and intended for use in sport hunting, in the educational and training process and during competitions;

sports crossbows (traditional, field, etc.), not related to throwing weapons, which are sports equipment intended for use in the educational and training process and during competitions;

crossbows for recreation and entertainment, not related to throwing weapons, which are household products intended for leisure and mass sports;

homemade crossbows (in terms of determining whether they belong to throwing weapons during forensic examinations).

The main criterion for gradation is the strength of the crossbow's arcs (Table 1).

Table 1

For the same guest there is the following classification table (Table 2). This is what concerns the legislation and standards of the Russian Federation.

table 2

Fig.5. Sports match crossbow.

But I would like to propose a slightly different classification of modern crossbows.

Classification by purpose:

1. Sports match crossbows

2. Copies, replicas of ancient crossbows

3. Crossbows for fun and recreation

4. Hunting crossbows.

With match crossbows (Fig. 5), in general, everything is clear - this is a separate class of crossbows that are a sports equipment and at the same time, according to the forensic requirements of the Russian Federation, a weapon. We will not dwell on them in detail.

Fig.6. Replica of a medieval crossbow (by "Dirty" Burdwood)

Next, in second class, are copies and replicas of ancient crossbows - military, sporting and hunting crossbows manufactured before the 20th century. That is, these are Greek gastraphetes, and arquebuses (a crossbow with a barrel), and schnappers with balestres (crossbows that fire bullets), as well as classic crossbows, with cocking devices improved over the centuries - with a belt hook, with a “goat leg”, with an English collar, with a cranekin. Naturally, according to the same forensic requirements, most copies, especially authentic ones, will be weapons. But replicas of ancient crossbows have only external similarities with the originals, and even then, often the external differences are so significant that only to a person completely inexperienced in crossbows, such products may seem like a copy (Fig. 6). Materials for manufacturing can be any, including a variety of polymers. Such crossbows may well fit within the legal limits of 43 kg. Copies and replicas of ancient crossbows are mainly souvenirs and museum products, as well as the path of fans and re-enactors of these weapons. Although, there are quite a large number of crossbow unions abroad that specialize specifically in antique crossbows and hold meetings, exhibitions and shooting competitions. But still, such crossbows are not suitable for recreational shooting, especially for spears, due to their power (again the notorious “43 kg”), the complexity of manufacturing ammunition (the shape of ancient bolts is mostly spindle-shaped), which often simply shatter into splinters upon impact o target.

Let me make a comparison: being interested in antique crossbows is akin to smoking a pipe. This is a manifestation of a certain aestheticism, listen to how such people speak about their hobby: “...to get pleasure from smoking a pipe, it takes time. This is a cigarette you can smoke while running, at work, in the toilet. Pipe is a ritual. Choose an hour or two, relax. Let the bustle leave you for a while. Slowly and carefully hammer in the tube. Relax comfortably in your favorite chair. Light it lovingly and take a mouthful of aromatic smoke. Release a puff of smoke and feel how all your problems dissolve in it. Your hand is warmed by a gentle and devoted friend, and in her beauty, in the convolutions of wood patterns and smooth lines, you will discover something new for yourself every time. Such beauty and devotion in women is sometimes more difficult to find than in pipes...” ( http://voffka.com/archives/2006/09/19/029976.html).

Let's move on to the so-called crossbows for entertainment and recreation. The majority of crossbows on the market are of this class. This includes pistol crossbows and rifle crossbows of all designs not exceeding a peak cocking force of 43 kg. Many crossbows in this group are from the following class - the hunting class, but with weakened shoulders by the standards of our country. Although with 43-kilogram shoulders, this is especially true for block crossbows, due to their design features, you can hunt small game and birds. For example, one of the record holders for arrow speed, Bowtech “Desert Stryker” (Fig. 7), was equipped for the Russian Federation with weakened arms of 43 kg.

Fig.7. Bowtech "Desert Stryker"

There are no serious design differences in hunting crossbows. The main thing is their powerful shoulders - up to 80 kg in block crossbows and up to 150 or more in classic crossbows. This allows you to send a heavy arrow with a broadhead tip (three or four bladed hunting tip) to the target with good energy. Naturally, hunting crossbows are always the most expensive and most well-equipped devices.

Classification according to the design of the power section.

1. Crossbows with classic shoulders:

a) with simple shoulders;

b) with recursive arms.

2. Block crossbows:

a) with a pulley system of 2, 4, 6 and 8 rollers;

b) with round eccentric blocks;

c) with oval eccentric blocks;

d) with binary eccentrics.

3. Crossbows with non-classical shoulder placement:

a) with reverse shoulders;

b) with a different arrangement of arms and a system of rollers (blocks).

Let's look at the above structures in order. Simple shoulders in a free state without a bowstring are a straight or slightly curved plate towards the shooter (mono-bow) or a pair of such plates (split shoulders). Most ancient crossbows had a monobow, but in modern crossbows split shoulders have become more common. An example of simple separate shoulders is a model from the Canadian company “Excalibur” for the teenage generation (Fig.. Also, such shoulders are not uncommon among home-made people due to the availability of material (springs from cars, as well as other spring elements - saws, torsion bars) and ease of manufacture An example of the author’s homemade product with shoulders made from a circular saw blade is shown in Fig. 2.

Fig.8. Crossbow Excalibur "Apex Light"

The majority of modern crossbows of the “classical” layout are equipped with recurve arms. Such shoulders differ from straight ones in that they have a characteristic and quite noticeable bend forward at the ends. In a free state, without a bowstring, the ends of such arms, as a rule, go forward further than the line of the bowstring and even further than the middle of the bow, forming an arc curved away from the shooter (Fig. 10). The degree of recursiveness can vary widely. Almost all crossbows produced by the same company “Excalibur” have such shoulders (Fig. 9, 10).

Rice. 9. Excalibur “Equinox” crossbow with recurve arms.

Rice. 10. Excalibur “VIXEN” crossbow front with arms without string.

Recursive shoulders can also be mono (Fig. 11) or split.

Fig. 11. Barnett "Commando" crossbow with a recurve mono arc.

Both simple and recursive shoulders are made with a narrowing from the root to the ends. Often both in width and thickness. This is done so that the shoulders bend when tensioned evenly along the entire length, or even a little more towards the ends, which helps to increase the efficiency of the shoulders - the weight decreases, the speed of straightening the shoulders increases.

Recursiveness helps achieve even greater efficiency. The curved ends of the arms provide additional leverage, which, as the bowstring is pulled, seems to increase the length of the arm, changing the distance from the center of rotation (from the center of the bow) to the bowstring. That is, as the resistance of the arc increases, the leverage by which we overcome this resistance also increases . Thanks to this, the recurve bow draws more evenly, its force changes less throughout the entire working stroke, and with the same tension as a regular (simple) bow, the recurve bow has a much greater preload*, which gives it the opportunity to push the arrow with greater force to the very end. In fact, there is a partial change in the “gear ratio” of the arc force to the string.

(*A bow with a bowstring installed, but in an uncocked state, is pre-tensioned, that is, it has a preload. The amount of preload is selected in such a way that the material from which the arms are made has a margin of safety for the required working stroke of the bowstring. That is, a compromise is found between the power of the arc and the properties of the material from which it is made. In simple words, we shorten the bowstring - we increase the preload, accordingly the power of the bow changes to a greater extent, but the chance of its breakage also increases with the ensuing consequences of possible injury to the shooter.)

The next stage in the development of crossbows was systems with a pulley system. The pulley is a clip with one or more round movable rollers (Fig. 12). In theory, depending on the multiplicity (the number of cable branches and the number of rollers) of the pulley, it is possible to reduce the tension force of the bowstring from two to four times (systems with two, four, six, eight rollers) and increase the speed of movement of the bowstring when shooting at the same number of times.

Fig. 12. The principle of operation of the block and pulley. a – single block (with one cable stretched along the groove of a single pulley); b – a combination of two single blocks with a single cable covering both pulleys; c – a pair of double-groove blocks, through four paired grooves of which a single cable passes.

Also, a system with a pulley system allows you to reduce the transverse dimensions of the crossbow, since the stroke of the end of the arm in them is significantly less with the usual length of the working stroke. In practice, in addition to the advantages, there are also disadvantages of this system: losses due to friction of the cable on the rollers, friction of their axes, movement of the mass of the shoulder shackles (earrings are the roller clips at the end of the arms), non-parallelism of the cable branches (strings, which in pulley systems significant).

In Fig. 13 shows an example of how by adding a pair of rollers and the same stroke of the ends of the arms, the stroke of the bowstring increases.

Fig. 13. Comparison of a pulley system with simple arms.

Most factory-designed pulley crossbows have eight rollers (Fig. 14). Crossbows with two rollers are extremely rare (Fig. 15), as well as with six – I can only cite as an example the wonderful homemade “Lynx” crossbow from Zmeelink (Fig. 16). There are many homemade devices with four rollers (Fig. 17), and there are also factory ones (Fig. 1.

Fig. 14. Crossbow Interloper "Black Python".

Fig. 15. Crossbow from Ralph's

On factory and many homemade crossbows, the middle rollers are connected to the next pair by a rod, as in Fig. 14, 17, 18, but practice has shown that it is better to make them rigidly fixed to the guide, which allows them to be lowered below the level of the rollers at the ends of the arms without interfering with the free movement of the bowstring and the straightening of the shoulders (Fig. 16, 19).

Rice. 16. Crossbow “Lynx” from Zmeelink

Rice. 17. Crossbow from daf13

Rice. 18. Crossbow-pistol Interloper “Aspid”.

Rice. 19. Crossbow with eight rollers, the middle ones are rigidly fixed

For optimal operation of pulley systems, the arms, relative to the guide, should be located as parallel to it as possible, since the bowstring acts on the ends of the arms through rollers, which tend to bend the arms not towards the shooter, but towards each other. That is, the sharper the angle between the shoulder and the guide, the better. Of course, if the shoulders are placed parallel, this will significantly reduce the transverse dimensions of the crossbow, but will also increase the longitudinal ones. Therefore, here it is worth looking for the “golden mean” - and the shoulders are rarely placed at an angle less than 45 degrees to the guide. A good solution was suggested by http://forum.arbalet.info/viewtopic.php?t=2802&postdays=0&postorder=asc&start=960 igora - pseudoparallel shoulders (Fig. 19).

Rice. 19. Pseudoparallel shoulders, by igora

As the author himself described it: “The essence of the proposed 2nd method is to make the shoulders of an ordinary one-piece monobow work just as parallel to the stock (which is what all manufacturers strive for) while remaining a regular arc and even without bending at all. At the same time, the gear ratio of the chain hoist used increases. Moreover, for example, in the figure, the chain hoist in the 2nd version will give a gear ratio approximately like that of an 8-roller, but in reality only two of them are added. Well (and most importantly!) the direction of the forces applied to the shoulder will be corrected). The biggest problem I see is the long string, but not longer than the 8-roller.”

The shoulders of pulley crossbows are made short and rigid, often without narrowing in width and thickness, because the stroke of the end of the shoulder in these systems is small, and the force that the shoulders must create is several times higher than in “classical” systems. The material of the factory shoulders is unidirectional fiberglass. Homemade, most often - springs from cars,

The pulley transfers force from the shoulders to the string through a certain gear ratio (which usually reduces the force and increases the stroke). But since this gear ratio is constant, then as the bending increases, the force on the arc increases in the same way on the bowstring. To get rid of this, and to further improve the shooting qualities of crossbows, so-called blocks appeared. They allow you to transfer force from the shoulders to the bowstring with a variable gear ratio, thereby ensuring that, regardless of the degree of bending of the arc and the force on it, the desired force is always on the bowstring. Some of the simplest blocks are round eccentric blocks. This is a more complex system compared to a pulley system - each block consists of two rollers secured together, the axis on which it rotates is offset from the center (Fig. 20). There are two bowstrings - one of two parts, connecting the power rollers of the blocks and the opposite ends of the arms, is called a power or technical bowstring (blue with a yellow fork in the figure), and the second is a combat or high-speed bowstring, which directly accelerates the arrow (white with a red winding, Fig. 21).

Fig.20. Round eccentric blocks (the hole for the axle is highlighted)

Rice. 21. System with round eccentric blocks

The layout and reeving of bowstrings in systems with round eccentric blocks is shown in Fig. 22. Also, the ends of the power strings can be attached not to the rollers at the ends of the block axes (Fig. 21), but by means of a transition piece under the block, attached to the axle (Fig. 23).

Due to the fact that the power string does not extend much lower than the speed string, it became necessary to lower it somewhat so that it does not interfere with the lower feathering of the arrow. Therefore, all crossbows with eccentrics have a characteristic slot for a power bowstring, with a guide part running inside it along with two slots for the left and right power bowstrings (Fig. 22).

Fig.22a. Location of blocks, string and pressing part (top view)

Fig.22b. Location of blocks, string and pressing part (bottom view)

Another feature of the eccentrics is that at the end of the tension, the operation of the block provides the so-called reset - a sharp decrease in the tension force. Therefore, in such crossbows, the tension force is measured by the peak force, and not by bringing the bowstring to the lock, as with simple and recursive arcs or in pulley systems.

Rice. 23. Barnett “Lightning” crossbow with round eccentrics.

The next stage in the development of crossbows was the use of oval eccentrics instead of round blocks (Fig. 24). The shape of these blocks only resembles an oval, but in fact it is more complex. The fact is that in such blocks, the force on the bowstring is controlled not only by simply shifting the axis of the block, but also by changing the very shape of the rollers that form the block. This allows you to create absolutely any desired force on the bowstring throughout its entire working stroke. A small illustration of the operation of an oval eccentric (Fig. 25 (by Andrey 74)) shows how the gear ratio between the power and speed parts of the block changes during its unwinding.

By combining the shapes and sizes of the power and speed parts of the block, as well as their relationship with each other, you can select the optimal characteristics of force, speed and stroke of the bowstring for specific shoulders. Examples of crossbows with oval eccentrics in Fig. 26, 27, 28.

Rice. 24. Oval eccentric blocks

Rice. 25. Illustration of the operation of an oval eccentric (author andrey 74)

Fig.26. Ten Point "Phantom"

Rice. 27. Darton “Serpent”

Rice. 28. Crossbow Parker “SAFARI CLASSIC”

On some models of crossbows with oval eccentrics, the blocks are installed in the opposite direction and the bowstring lies on the side opposite to the shooter - these are the so-called “mirror blocks” (Fig. 29). In this case, the crossbow becomes somewhat more compact in the longitudinal direction than with the usual arrangement of eccentrics.

Rice. 29. Parker “Cyclone” crossbow

Recently, there has been a tendency to increase blocks almost to the size of archers. By winding more string from the blocks, we get a larger stroke of the string, which means that the transverse dimensions of crossbows can be further reduced. Despite the fact that with such large eccentrics, the stroke of the crossbow string approached 45 cm! The most striking representatives of the new generation of crossbows and record holders for arrow speed are the PSE “TAC-15” (Fig. 30) and Bowtech “Stryker” (Fig. 32) crossbows. Both crossbows are unique in their own way.

Let's take a closer look at the TAC-15. Due to its huge eccentrics, the width from axis to axis of the blocks in the uncocked state is 42.5 cm, and in the cocked state - 29.8 cm. And the stroke of the bowstring is a record for a crossbow - 45 cm! With a peak force of 77.2 kg, it is capable of sending a 425 grain (26.44 g) arrow at a speed of 125.6 m/s. At this time, this is an absolute record for crossbows. The kinetic energy developed in this case is up to 217 J, sufficient for hunting any large animal. The crossbow is also unusual in that the back of the crossbow is from an AR-15 (M16) automatic rifle - as you know, this rifle has a modular design (Fig. 31). Therefore, any weapon based on the M16 can be easily converted into a crossbow. The TAC-15 has a built-in winch-type cocking device. One more point - the arrow of this crossbow does not lie on the guide, but, like a bow, rests with its leading edge on the shelf. And the arrows recommended by the manufacturer also have a record length for crossbows - 26.25 inches (~66.7 cm)!

Rice. 30. Crossbow PSE “TAC-15”.

Rice. 31. AR-15 rifle

Rice. 32. Crossbow Bowtech "Stryker"

The Bowtech "Stryker" crossbow has slightly more modest characteristics, it launches an arrow weighing 425 grains at a speed of 123.4 m/s, while having a kinetic energy of 210 J. Its width from the axis to the axis of the block in the untensioned state is 69.2 cm, and when stretched it is 61.6 cm, the peak tension force is 79.45 kg with a bowstring stroke of 432 mm. But the Stryker has one feature - binary eccentrics, which classifies it as the next subclass of compound crossbows.

What are the differences between binary eccentrics and ordinary oval ones? Let's try to figure it out. All compound crossbows have one bad feature - the center of their bowstring (arrow stop) can shift to the left or right due to the fact that each one rotates independently, as a result of which shooting accuracy decreases. In binary systems, the blocks have an additional third pulley, onto which the other end of the power string on the right or left side is wound, due to which synchronization occurs (Fig. 33. (author igora)). In Fig. Figure 34 shows for clarity an example of a binary eccentric of a compound bow.

Rice. 33. Illustration of the operation of binary eccentrics from igora

Rice. 34. Binary eccentric compound bow

Even the brilliant Leonardo da Vinci came up with a design for crossbows with reverse arms (Fig. 35), and only recently did crossbows of this design begin to be mass-produced. The first sign was the Armcross "LeoPro" crossbow, created by Russian designers (Fig. 36). The main advantages of such crossbows are: compactness (reduced longitudinal and transverse dimensions), better weight distribution, reduced shot recoil, because when shooting, the shoulders do not move away from the shooter, but as if to each other and a little “into the shoulder.” In Fig. 37 you can see how compact the LeoPro is. Among the disadvantages of a crossbow, we can highlight the sharp angle of tension of the bowstring (Fig. 3, due to which it is convenient to cock the crossbow only using a cocking device, and also, purely hypothetically, it can be assumed that the shoulders, which are too close to the shooter’s face, can break injure.

Rice. 35. Schemes by Leonardo da Vinci

Rice. 36. Crossbow Armcross "LeoPro"

Rice. 37. Crossbow Armcross "LeoPro" with a specially designed unloading vest

Rice. 38. Cocking the Armcross "LeoPro" crossbow using a tensioner (shown below to the right)

Rice. 39. Crossbow Horton “Recon 175”

Another crossbow with reverse arms is produced by the Horton company - “Recon 175” (Fig. 39). Please note that both of the most famous crossbows with reverse arms have round eccentrics, which does not prevent them from showing very good characteristics - the initial arrow speed reaches 99 m/s.

It is not advisable to make such crossbows with a classical layout, that is, without blocks, since the shoulders will “run away” in the direction opposite to the tension and the efficiency, relative to crossbows with a classically located arc, will be much lower.

Recently, another player has appeared in the camp of crossbows with reverse arms - “Scorpyd” (Fig. 40). According to new trends, its blocks are binary and large in size. The stated initial speed of the arrow is 425 feet per second, which corresponds to 129.5 m/s! The stroke of the bowstring of this compact crossbow reaches a record 52 cm!

Rice. 40. Crossbow “Scorpyd” SLP

Among homemade products there are also crossbows of a similar design. Almost all have a similar “LeoPro” design, but mostly with a pulley system with two or four rollers (Fig. 41, 42, 43).

Fig.41. Crossbow from OLEKS

Fig.42. Crossbow from sa1982

Rice. 43. Crossbow from Frank

So, it’s time to touch on the last type of crossbow with a non-classical arrangement of shoulders - this is a crossbow that was released by the Swiss company Swiss Crossbow Makers - “Twinbow II” (Fig. 44). This crossbow is unusual not only in the location and operation of the shoulders, but also in its unique cocking device (Fig. 45). With compact dimensions (length 875 mm, width 420 mm) and a bowstring stroke of only 197 mm, it has very good power - with a tension of 180 kg, arrow speed of up to 113 m/s and energy of 145 J! When the bowstring is tensioned, the arms become almost parallel; both ends of each arm work through a roller system. As a result, the recoil when shooting from such a powerful crossbow is practically not felt.

Fig.44. Crossbow “Twinbow II”

Fig.45. Cocking the Twinbow II crossbow

There are several homemade crossbows made according to the “Twinbow II” design. The gunsmith111 crossbow (Fig. 46) uses a twin system without a cocking lever. But on shushai crossbows the main feature of the Swiss is implemented - cocking with a lever (Fig. 47 and 4.

Rice. 46. Crossbow from gunsmith111

Rice. 47. Crossbow “Twilight” from shushai

Rice. 48. Crossbow “Cyclone” from shushai

PART 2

3. Triggers of modern crossbows.

As mentioned above, the trigger mechanism (lock) of a crossbow can be an integral part of the design of the guide (stock) or can be mounted in a separate housing. The latter are found much more often both among crossbow manufacturers and home-made people, due to the convenience of installing a ready-made trigger mechanism (SM) in any place.

With all the variety of modern crossbow triggers, locks can be divided into three main types:

a) with a lower hook (nut, cracker) (Fig. 49a);

b) with an upper hook (Fig. 49b).

c) with a fixed hook (pin lock) (Fig. 49c)

A)

b)

Rice. 49. Triggers with lower (a) and upper (b) hook

Attention: when using materials from this article, a link to the site, as well as an indication of the author of the article REQUIRED!